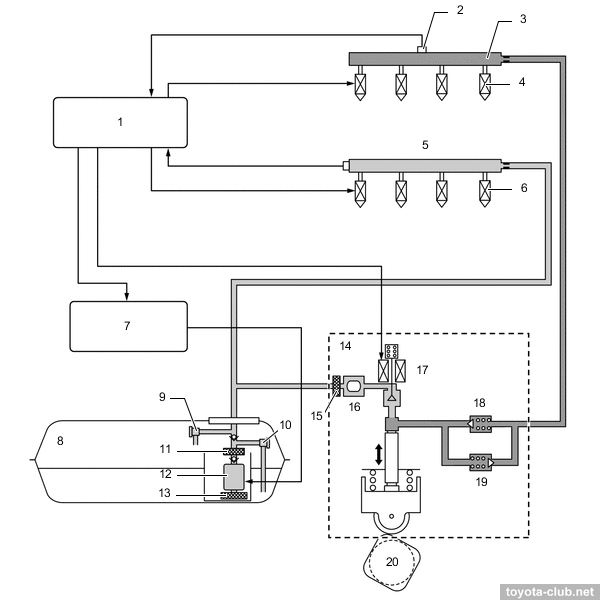

Fuel system (D-4S)

1 - ECM, 2 - fuel pressure sensor (high), 3 - fuel rail (high pressure), 4 - direct fuel injector, 5 - fuel delivery pipe with sensor (low pressure), 6 - port fuel injector, 7 - fuel pump ECU, 8 - fuel tank, 9 - fuel main valve (high pressure), 10 - fuel main valve assembly (low pressure), 11 - fuel filter, 12 - fuel pump (low pressure), 13 - fuel suction filter, 14 - fuel pump (high pressure), 15 - fuel sus filter, 16 - fuel pressure pulsation damper, 17 - spill control valve, 18 - check valve (60 kpa), 19 - fuel relief valve (26.4 MPa), 20 - exhaust camshaft. |

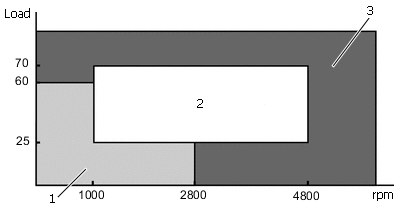

Fuel injection - combined: directly in the combustion chamber and multipoint in the inlet ports. At low to medium loads - combined injection is applied - homogeneous mixture increases the stability of the combustion process and reduces emissions. Under a heavy load use direct fuel injection - the evaporation of the fuel in the cylinder filling mass improves and reduces the tendency to knock.

1 - injection in port, 2 - injection in cylinder + port, 3 - injection in cylinder. |

- Stratified combustion mode. Fuel is supplied in the intake ports on the exhaust stroke. On the intake stroke after the opening of the valves in the cylinder receives a homogeneous lean mixture. At the end of the compression stroke, additional fuel is injected directly into the cylinder, allowing to enrich the mixture near the spark plug. This facilitates the initial ignition, is then distributed on the all lean mixture charge in the remaining volume of the combustion chamber. This mode is applied after a cold start to retard ignition timing and to increase the exhaust gas temperature for accelerate catalyst warming up.

- Homogenous mixture mode. Fuel is supplied in the intake ports on the expansion, exhaust and intake strokes. At the beginning of the intake stroke, additional fuel is injected directly into the cylinder and evenly mixed with the incoming charge. Homogeneous air-fuel mixture is compressed and then ignited. Due to the evaporation of injected fuel, air charge in the cylinder is cooled improves cylinder filling.

Review of Toyota Dynamic Force engines design and components - inline-4 (M20A, A25A)

toyota-club.net