Originally Posted By: InfmousCornholio

I'm actually more worried about "filing down" the bolt than cleaning the threads.. I know that file will get the metal down..

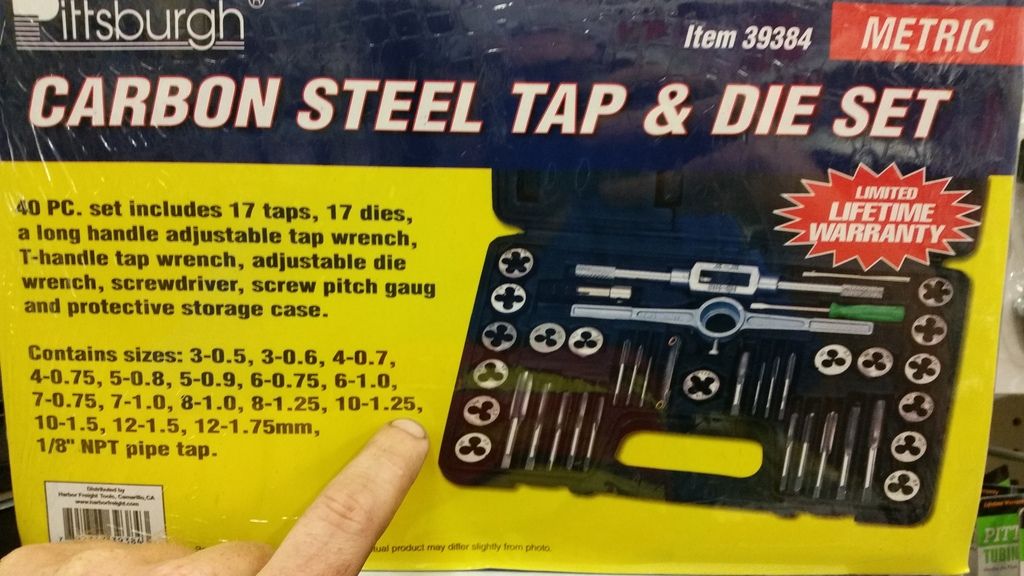

You aren't listening. You use the DIE from your tap and die set, to clean the threads of the bolts to make sure they are obstruction-free. You no longer need the file with the tool kit you bought.

Originally Posted By: InfmousCornholio

I actually plan on returning that HF unit pictured, and this is coming in the mail.. It is a tap, with a Heli-Coil.

https://www.amazon.com/gp/aw/d/B0002SRG3...d=ATVPDKIKX0DER

You are again getting ahead of yourself. Why do you think you need a heli-coil? So you can further bugger the engine? You don't even know if anything is stripped yet and subsequently in need of this.

Use the tap from the kit you just bought, the one that is the same thread as the bolts, and gently work it down the holes to clean them. Do this several times, WITH LUBRICANT. DO NOT BOTTOM THEM OUT.

With the threads on the bolts chased with the die and the threads on the block chased with the tap, the bolts should thread easily.

Originally Posted By: InfmousCornholio

I'm not sure why some would say the threads can't be tapped. I welcome input from all sides, but you all should know me by now.. I want to get it right.

Then stop jumping around like a rabid mongoose and pay attention. Read this thread. Then read it again. Good advice has been given, you are doing exactly what you always do which is go off half cocked on a crazy tangent and then wonder why things get buggered up.

People are telling you to be careful with the threads on the aluminum block because they are easy to bugger up and if you bugger them up, they need something like a time-sert in order to be usable again.

Originally Posted By: InfmousCornholio

I'll revisit cleaning and threading tomorrow.. Again, the ones in the back went well and the ones in the front have some kind of issues.

Those issues may just be filth and/or corrosion from the engine sitting outside with no head on it. This is why a proper inspection and cleaning is needed to assess what's really going on.

This is NOT complicated but it requires patience and understanding, both things that are not your forte so again I invite you to read and then re-read what has been said here until you are CLEAR on it and it has sunk in.