Originally Posted By: zrxkawboy

Can you now see why "greater than 20" and "equal to 20" are so different? In the first race, I mopped up because "greater than 20" included so many older guys, and that helped my average immensely. In the second race, all my competitors were 20, and so it was a much more difficult test.

Your analogy really doesn't jive with this discussion. You have to understand the ISO 4548-12 test to be able to understand that ">20 microns" is basically saying "at 20 microns".

The ISO 4548-12 test uses real time particle size measurement and counting instrumentation before and after the oil filter as oil is flowing through the filter. Here is a synopsis of ISO 4548-12.

================

Methods of test for full-flow lubricating oil filters for internal combustion engines --

Part 12: Filtration efficiency using particle counting, and contaminant retention capacity.

This part of ISO 4548 specifies

a multi-pass filtration test with continuous contaminant injection and using the online particle counting method for evaluating the performance of full-flow lubricating oil filters for internal combustion engines.

The test procedure determines the contaminant capacity of a filter, its particulate removal characteristics and differential pressure.

This test is intended for application to filter elements having a rated flow between 4 l/min and 600 l/min and with an efficiency of less than 99 % at a particle size greater than 10 microns.

ISO 4548-12 uses "muti-pass" filtering methods, versus a "single-pass" test method.

========================

Also see the "Multi-pass testing" (2nd paragraph) in this article.

http://www.lenntech.com/library/fine/beta/beta-ratio.htm

Here's another good link that explains filter testing, mulit-pass tests and beta ratio (ie, filter efficiency).

http://www.machinerylubrication.com/Read/564/filter-beta-ratios

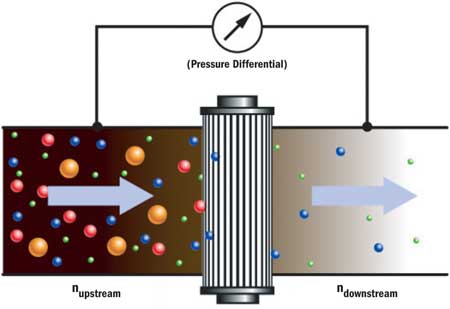

Here is a schematic showing the multi-pass test setup.

Here's a discription of the test procedure.

============================

"Test dust of a known particle size distribution is added to the fluid in the injection reservoir until it reaches a specified concentration in grams of contaminant per liter of test fluid. The fluid in the injection reservoir is then pumped continuously into the clean fluid in the test reservoir, thereby creating a low concentration test solution. This test solution is circulated continuously to the test filter at a constant flow rate. The test solution is filtered by the element under test and travels back to the test reservoir (along with any unfiltered particles). This cleaned fluid is contaminated again by the injection fluid, and is once again pumped to the test filter.

During the test, the element differential pressure, the upstream and downstream particle counts and the amount of injected contaminant are continuously monitored. In most instances, the multi-pass test is completed when the element differential pressure reaches the specified limit or the Beta Ratios fall below a specified level."

============================

So, as particles are injected to the oil source the size of the particles are continuously upstream and downstream at the same time and the numbers are compared to determine the efficiency of the filter over the entire range of particles.

You might see a distribution like this from the test results:

5u = 50% efficient

10u = 70%

15u = 90%

20u = 99%

25u = 99.5%

30u = 99.9%

40u = 100%

50u = 100%

Any filter is going to become more efficient filtering out larger particles than smaller partials, so the distribution will always show increasing efficiency as particle size increases.

In a distribution like shown above, the tester can conclude that this filter will take out 99% of all particles that are 20 microns and larger. He could say the filter is 99% for particles >20 microns to be "conservative", or he could actually say it's 99% @ 20 microns.

So the ISO efficiency test is comparing each size of particle before and after the filter to see how each size is filtered out. That's the whole key to understanding that saying ">20 microns" is essentially the same as saying "at 20 microns".