It has been my line of study for the last 55 years or so.

The topic here was reasons for thinner oils. I just listed one item of concern.

And how thicker lube will not flow so great through a fine mesh screen.

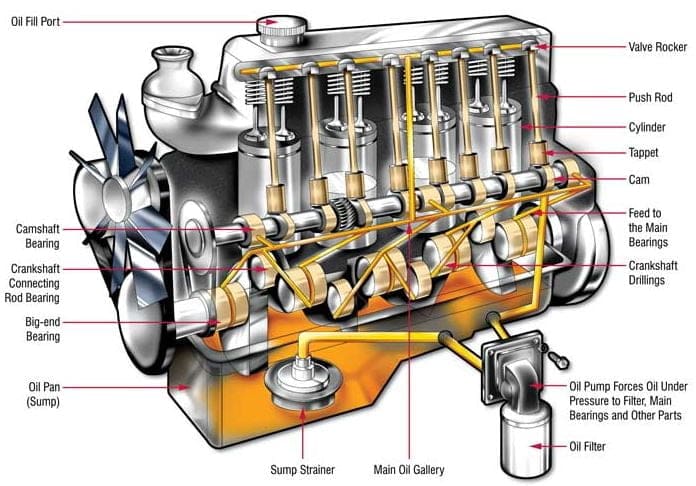

Oil flowing under gravity is irrelevant to the discussion here since engine oil is under pressure to create the proper flow rate. Here is a basic explanation of a pressurized oil system:

In this article, we are going to study Different Types of Lubrication System: Advantages and Disadvantages in detail. You can

themechanicalengineering.com

As others have stated, lower viscosity oils are mostly for CAFE (Fleet Mileage) mpg targets.

Lower viscosity oils also reduce the amount of HP needed to move the engine oil under pressure, which, in turn, reduces oil temperature ever so slightly, but we're talking small fractions of gains here.

@Exhaustgases Oil viscosity is not tested in an engine.

I am not sure what this means. Oil viscosity verses temperature is tested in the Lab to predict the bulk oil viscosity in engines at various operating temperatures.

Now if your main concern is maximum oil viscosity verses VVT solenoid and phasor operation, then yes, there is a maximum oil viscosity specification. In both my old 5.3L Trailblazer engine and in my old 2003 PathFinder 3.5L engine (both of which I no longer own), the maximum viscosity spec was a grade of 10W30. This assumes those "last chance" screens and VVT control-valves are free of carbon.

Check your Owner's Manual for the Minimum and Maximum oil viscosity allowed.

Again, if you are concerned about keeping those VVT components clean, this product is highly recommended:

HPL Engine Cleaner is designed for those who wish to clean deposits in their engines left behind from commodity type lubricants that are designed to “meet the spec.” Engine Cleaner is specially formulated and fortified with detergents and dispersants providing safe cleaning in the engine. When...

www.advlubrication.com