JHZR2

Staff member

Old as in 35 years old. Like I was barely alive when it was made...

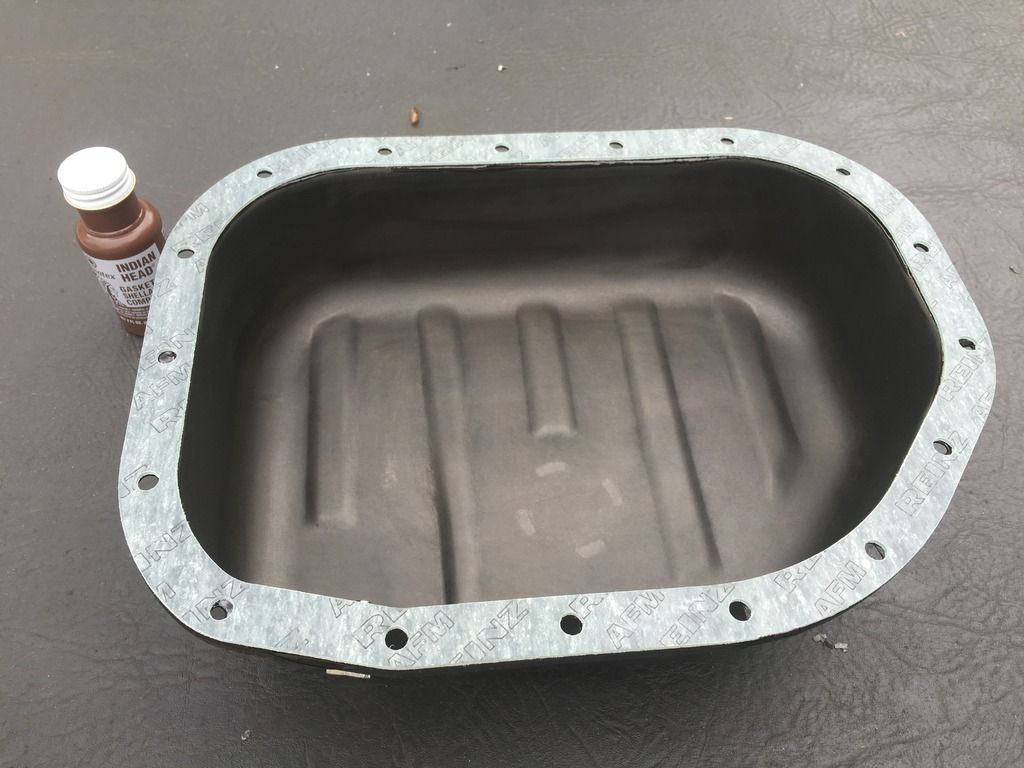

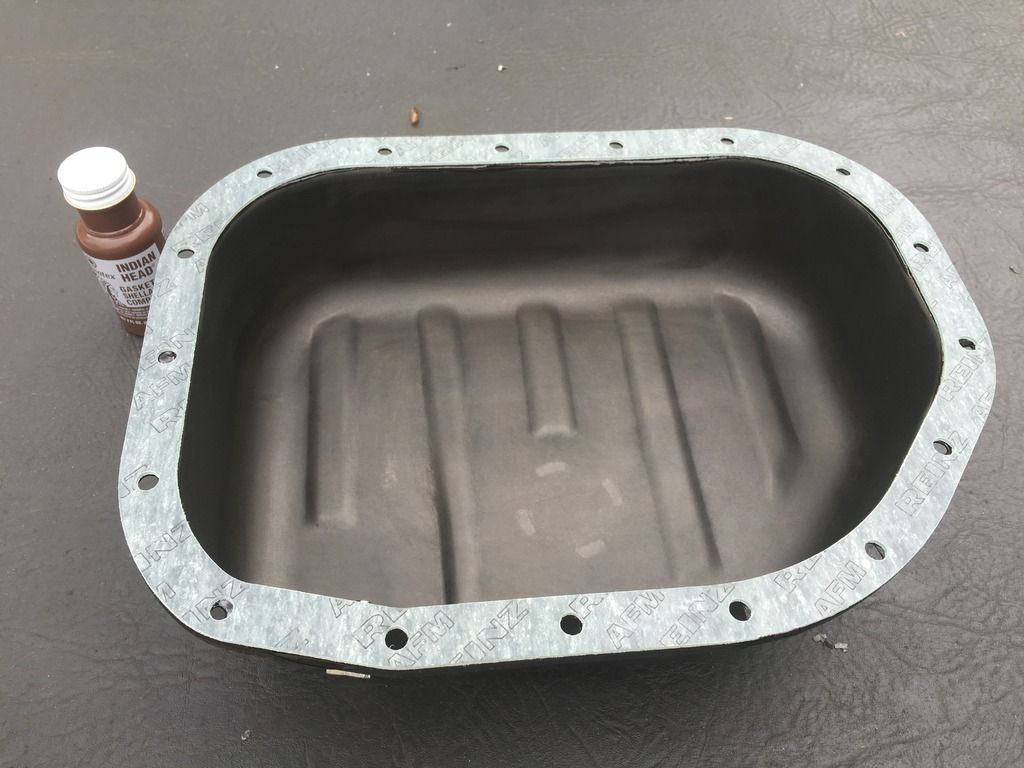

It is an OE Reinz gasket on my 81 240D oil pan. It started seeping, a lot, so it was time for a change.

Most of it came off well and easily. It was a perfect clean break from the engine block... But was stuck well to the pan...

They obviously used some adhesive or sealant around the holes to prevent leaks...

This kind of residue:

I tried a few things - white paper towels, blue paper towels, some solvents, and a razor blade. The towels were too linty, the solvents helped a bit, but the razor was really what was needed.

After scraping, flushing with some aerosol solvent to help get rid of lint, then blasting with compressed air, it looked ok.

I used Indian head shellac on both sides. I applied to the pan, then set the gasket, then applied to the gasket and bolted the pan up. Smells like natural vanilla extract!

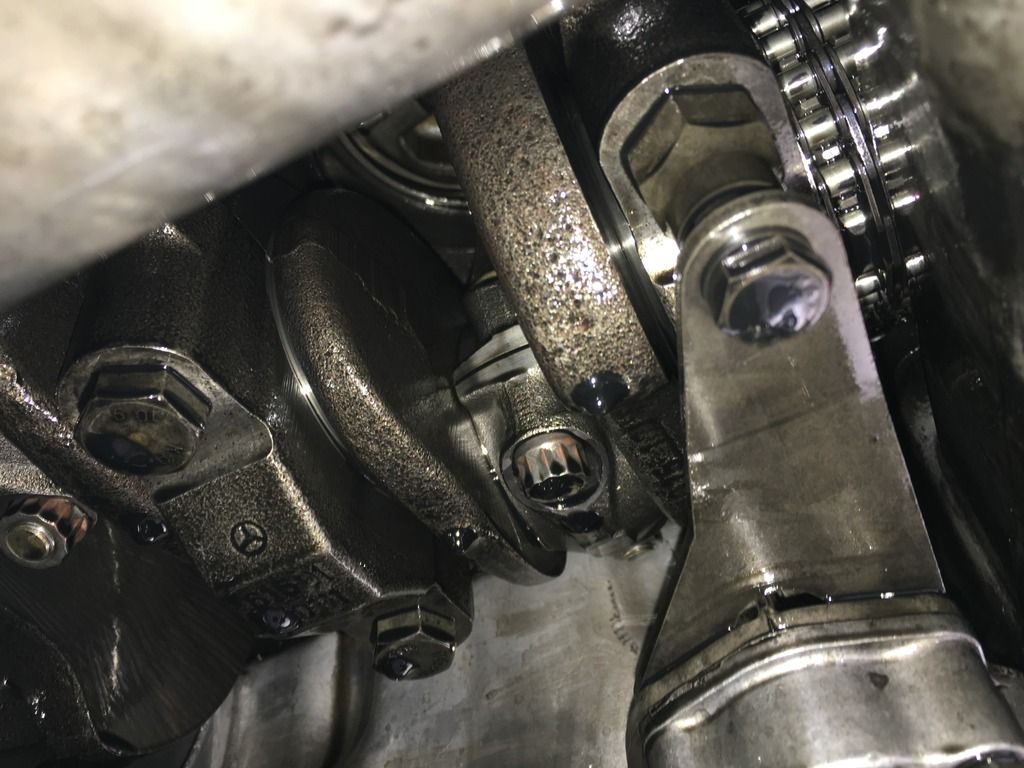

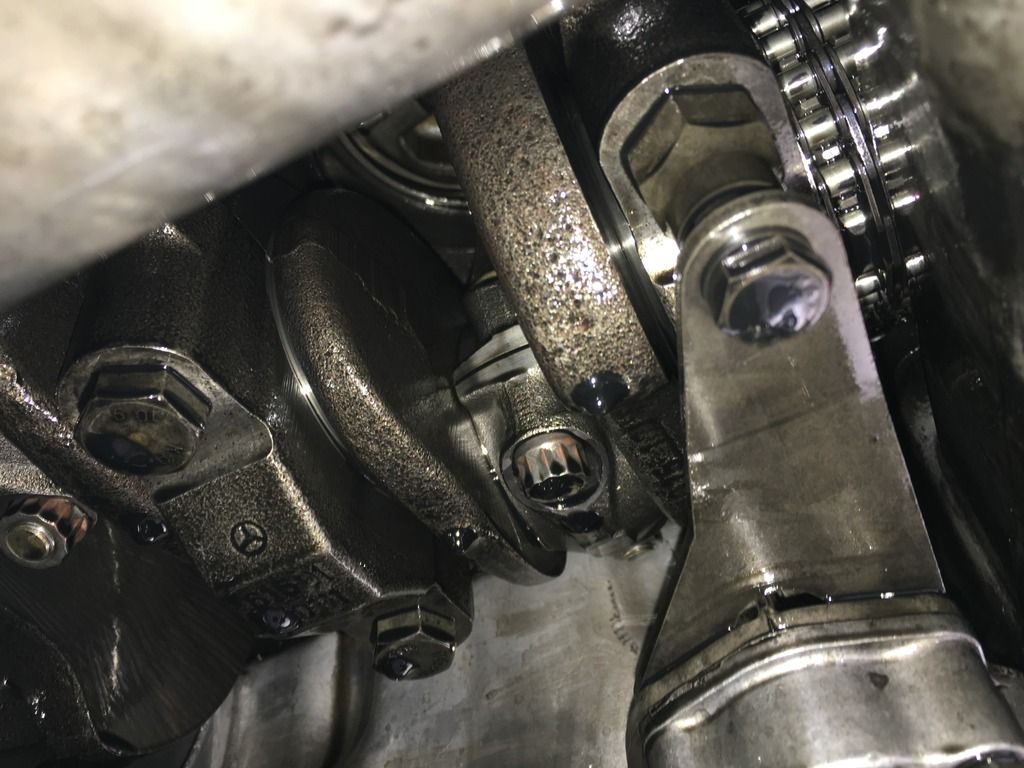

Things looked good up above...

So, please critique. Should I have done something else to prep the pan, given the residues left on there? It was easy to start scratching away the paint in the pan if not careful, so depth control was an issue. I'm not sure a wire brush or some such thing would have helped in that regard.

Comments? Critiques?

It is an OE Reinz gasket on my 81 240D oil pan. It started seeping, a lot, so it was time for a change.

Most of it came off well and easily. It was a perfect clean break from the engine block... But was stuck well to the pan...

They obviously used some adhesive or sealant around the holes to prevent leaks...

This kind of residue:

I tried a few things - white paper towels, blue paper towels, some solvents, and a razor blade. The towels were too linty, the solvents helped a bit, but the razor was really what was needed.

After scraping, flushing with some aerosol solvent to help get rid of lint, then blasting with compressed air, it looked ok.

I used Indian head shellac on both sides. I applied to the pan, then set the gasket, then applied to the gasket and bolted the pan up. Smells like natural vanilla extract!

Things looked good up above...

So, please critique. Should I have done something else to prep the pan, given the residues left on there? It was easy to start scratching away the paint in the pan if not careful, so depth control was an issue. I'm not sure a wire brush or some such thing would have helped in that regard.

Comments? Critiques?