Originally Posted By: Gokhan

Originally Posted By: Clevy

Originally Posted By: tig1

Why do you guys hate XM? I hear you say it but no explaination.

Years ago I was an M1 fanboy. Then I got caught up in the whole basestock debacle,then the castrol hearings and I just swung over to the Amsoil bench.

And if you like a Amsoil you naturally have to hate Mobil.

Then I tried it out for old times sake and my engines got very noisy and I didn't like that they cheapened the basestocks after the castrol thing but the cost to the consumer didn't change so I just decided that's it,no more Mobil.

I'll buy the stuff when its cost effective and on sale but I won't go out of my way to search got it.

Originally Posted By: Gokhan

Elastohydrodynamic-lubrication (EHL) film thickness is given by (

reference):

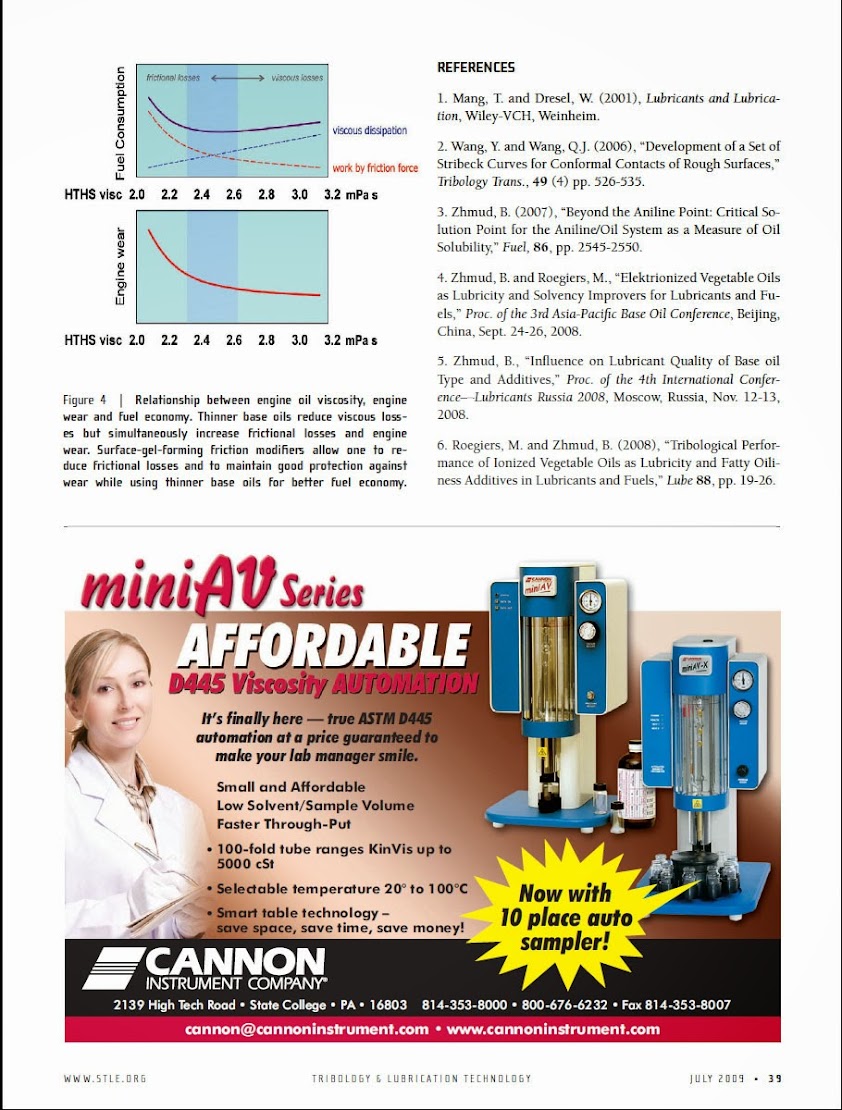

Here H_c is the EHL film thickness, alpha is the pressure - viscosity coefficient, and eta_0 is the high-shear (HTHS) viscosity.

The goal is to have the pressure - viscosity coefficient as high as possible, as well as the HTHS viscosity, to achieve a higher EHL film thickness.

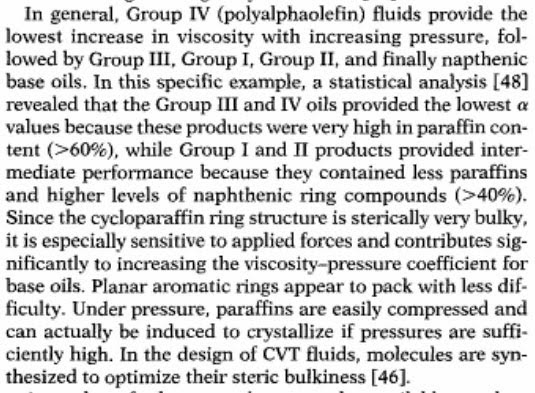

Unfortunately, Group IV (PAO) has the smallest pressure - viscosity coefficient, followed by Group III, which is followed by Group II. Group I has the largest pressure - viscosity coefficient. Here is why (from page 180 of the

reference):

Therefore, synthetic oils will give smaller oil film thickness than Group II oils and Group II oils will give smaller oil film thickness than Group I oils in the EHL regime. EHL regime and boundary-lubrication regime both apply to the valvetrain.

One advantage of synthetic oils is that, due to their use of lower concentration of viscosity-index improvers, their HTHS viscosity will shear less than for conventional oils over the OCI. Higher HTHS viscosity is good for oil-film thickness. Therefore, synthetic oils will maintain their oil-film thickness better than conventional oils over the OCI.

After all this said, am I worried about using synthetic oil? No, I am not. I believe the most important protection against wear in the valvetrain is ZDDP, moly, and other antiwear additives. So, if you have a decent concentration of quality (mostly secondary kind) ZDDP, the trinuclear kind of moly, and some additional quality AW/EP/FM additives, you should have good wear protection in the valvetrain regardless of the viscosity or the pressure - viscosity coefficient. This is not a proven statement though but more my current understanding. Engine tests are always the most authoritative in reaching a conclusion.

So this explains why conventional oils tend to make an engine very quiet,because the oil film is thicker but not necessarily stronger.

Am I to infer that yes a conventional oil has a thicker oil film at any given temp however the film strength is lesser than their synthetic counterparts?

Thanks in advance for any answers if you know them.

I don't think "oil-film strength" is a scientific term.

If you mean how much pressure it takes an oil before it's squeezed out in the EHL regime, it's the same as oil-film thickness. If you mean how much protection an oil offers in the boundary lubrication regime, it mostly has to do with the AW/EP/FM additives and has little to do with the base oil.

Therefore, "oil-film strength" is primarily a gimmick used by some boutique synthetic-oil manufacturers.

The bottom line is that Group I base oils provide better wear protection than Group II, which provide better wear protection than Group III, which provide better wear protection than Group IV and GTL in the EHL regime. This is because their pressure - viscosity coefficient is higher and they maintain thicker oil films under high-pressure conditions.

Does this mean that we should worry about using synthetic oil because their oil film breaks down more easily than conventional oil in the EHL regime? Probably not. I know Mobil 1 had poor wear protection in their SM formulation but this has been corrected in their SN formulation. Even if the oil film breaks down and you go into boundary lubrication (metal-to-metal contact), than the AW/EP/FM additives will protect against wear. Besides, I believe the valvetrain primarily works in the boundary-lubrication regime to begin with, and thereofe the AW/EP/FM additives, not the base oil, is the most critical factor there.

That was an awesome explanation. Thank you for correcting me. I was mistaken on a few points which you've clarified in a stellar fashion for me.

Thank you very much. Fantastic explanation.