Last year I started getting a ton of blow by to the point it would push your hand off the breather hole in the valve cover. Engine ran and sounded fine but I knew something was wrong.

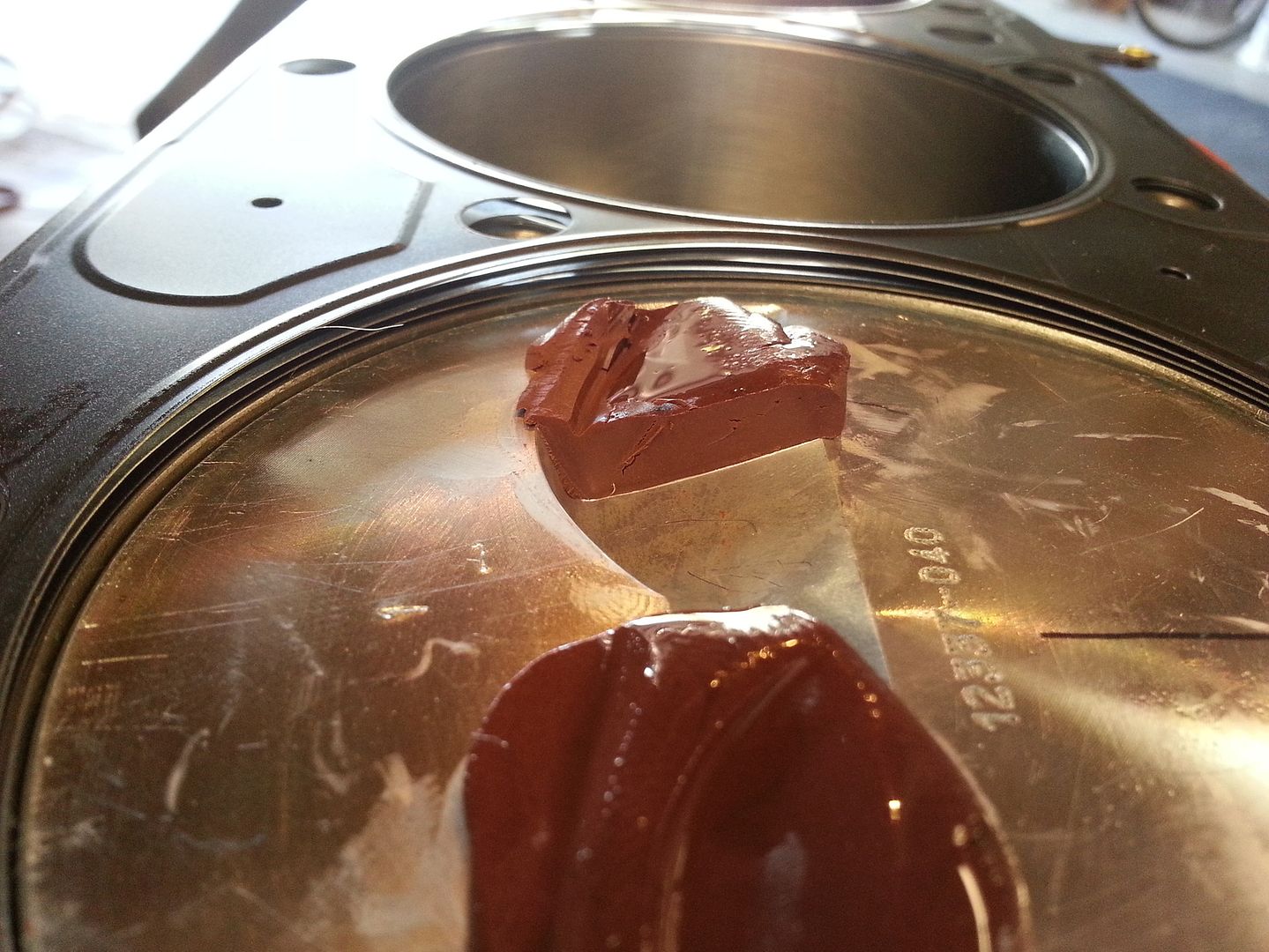

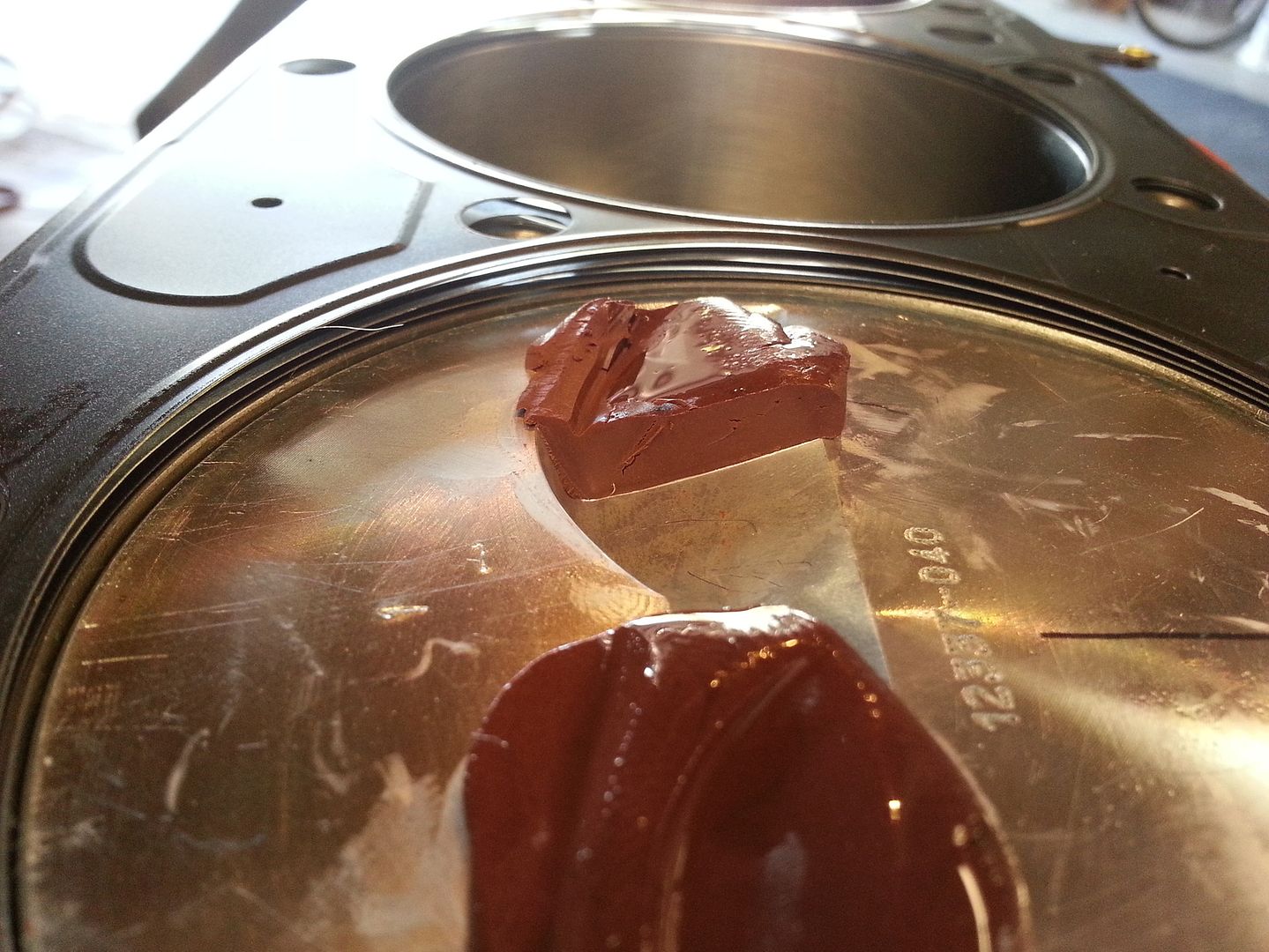

Whoops

Had it taken out to 4.040 and torque plate honed, decked, mains honed etc etc. It is now a 385 with 10.83:1 pump gas compression.

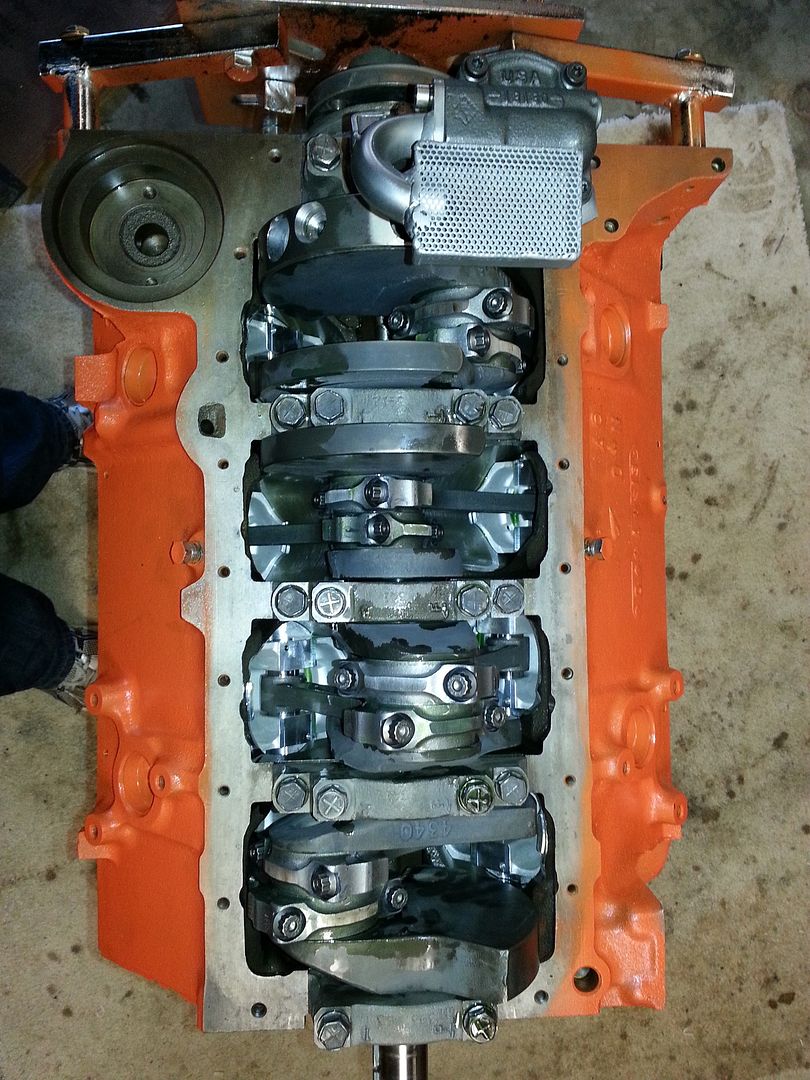

Here she is coming together

What do I spy cnc heads????????

The baby cam

The $1000 solid roller lifters. These have no needle bearings to go bad and drop into and wipe the engine.

Yup tons of clearance after Probe fly cut the pistons

Also sent my super comp's out to nitroplate to be coated and here she is together and ready to install.

Doing some tuning

http://youtu.be/vIQqzKXRtZw?t=48s

One of the rear oil galley plugs was leaking and we had to drop the trans to get to it. Here we are testing it to verify we fixed the leak before putting the trans back in. No exhaust here.

http://www.youtube.com/watch?v=HE27VqHn0Kk

Whoops

Had it taken out to 4.040 and torque plate honed, decked, mains honed etc etc. It is now a 385 with 10.83:1 pump gas compression.

Here she is coming together

What do I spy cnc heads????????

The baby cam

The $1000 solid roller lifters. These have no needle bearings to go bad and drop into and wipe the engine.

Yup tons of clearance after Probe fly cut the pistons

Also sent my super comp's out to nitroplate to be coated and here she is together and ready to install.

Doing some tuning

http://youtu.be/vIQqzKXRtZw?t=48s

One of the rear oil galley plugs was leaking and we had to drop the trans to get to it. Here we are testing it to verify we fixed the leak before putting the trans back in. No exhaust here.

http://www.youtube.com/watch?v=HE27VqHn0Kk

Last edited: