Well, I finally got a chance to look at this and respond like I said I would. I merged your two posts into one response.

Originally Posted By: Gary Allan

I used a Permacool sandwich adapter with the poppet relief welded shut. I then routed it to a dual Permacool filter mount where I used a block adapter on one of the filter mounts and a filter on the other. Hence pressure was read above and below the filter. This was routed to the two pressure gauges that you have seen. I later installed a 0-20 (or maybe 0-15, I had two - one stolen with the van) differential pressure gauge across the same setup.

The only time there was ever any appreciable PSID was during a relief event. That would be where the upstream reading attenuated (it always reached this pressure upon cold start) @ 82psi and the downstream side stopped at a lower level. Then the basement rose to (almost) meet the ceiling. This was always the case.

A loaded filter (9k) merely increased the level of PSID and elongated its duration upon startup ..but produced no substantial static PSID. That is, the 9k filter quickly retreated to 4PSID and then retreated even more as the oil warmed. @150F oil temp, running the rpms up into higher speeds (like the shifting point @ WOT but not achieved using WOT) produced a "surge" of PSID that retreated.

Nothing surprising here. Just as I’ve said many times, the max filter PSID and max engine oil pressure will always occur when the pump is in relief mode (under constant viscosity conditions as always). That is because when the pump is in relief mode, the max possible supply pressure is on the filter/engine flow path, and that will produce the max amount of oil flow at that instant in time. The corresponding filter PSID and engine oil pressure at that instant in time will be dependant on the volume & viscosity of the oil flowing through the system.

Of course if the engine PRM is decreased, and/or as the oil starts to warm up, then eventually the pump will go out of relief mode and the filter PSID and engine oil pressure will retreat (decrease) accordingly.

Originally Posted By: Gary Allan

I did see one event where the differential gauge reached the range of the normal Purolator bypass setting on the 9k loaded filter with 15w-40 oil @ 28F with overnight temps of the low 20's/high teens. The condition was brief ..like 30 sec.

Not surprising. Obviously with oil that viscous the pump was in relief mode supplying its max pressure. Even though the oil flow volume going to the filter/engine was much less, the high viscosity factor has a large influence on filter PSID and engine oil pressure. The filter was probably loaded enough to cause the flow’s volume & viscosity combo to create a PSID greater than the bypass setting. It’s also possible that the system was probably not fully pressurized initially upon startup for the first few seconds (up to 30 sec ?? – who knows) due to the oil being so viscous. This would cause an initial higher “in-rush” oil volume through the filter until the engine circuit was filled to produce the normal backpressure on the system which would then lessen the flow rate and filter’s PSID.

Originally Posted By: Gary Allan

With a new Pureone filter, the smallest one that they make in the 3/4-16 thread (or I could find, maybe) ..I thought the gauge was broken. I had to wonder if the blip that I thought I saw was a placebo effect, or some vibration from the engine on initial firing. It was that "unremarkable".

I’m assuming the same cold oil start-up conditions applied to this filter? If so, this doesn’t sound like a normal response. I would expect some noticeable/visible PSID at these cold startup conditions with any oil filter in the system. Maybe the gauge didn’t like the cold weather that day, or maybe the bypass valve was stuck open all the time. Hard to say.

Originally Posted By: Gary Allan

This would not be the situation with all engine/filter combo's. My 2.5 jeep resides at or near the relief level all the time. Depending on what visc oil I use, I would be in some state of elevated PSID based on visc (mostly) whenever off idle. Same with my wife's HV pump's 4.0. Both are slammed up against the relief most of the time. You have to use 20 grade in the 4.0 to "fit" all the volume through at full warm up ..with the 2.5, I THINK, I can manage to get into a decent range of flow within the relief limit. Throw in 5w-40 ..and neither will be out of relief. THEN the PSID will vary depending on visc. The higher PSID will retreat to a lower PSID.

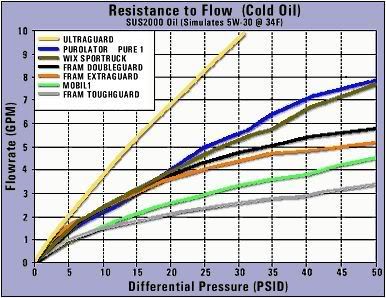

A good reason to ensure the oil filter being used is matched to the vehicle in terms of flow resistance (ie, element size and flow vs PSID characteristics) and bypass valve setting. Just like the Subaru application (high volume oil pump!) this thread is focused on ... if you used a filter with a much lower bypass setting than specified, the filter could certainly be in bypass mode much more and much longer than really desired. I think we all have agreed to that conclusion.

Originally Posted By: Gary Allan

Here's a state that I think you've failed to consider (me too, for that matter). It will probably work with your basic rationale to this whole deal.

If a pump was in perpetual relief, all of your assumptions about filter resistance will be 100% valid (at least I think so). There you would/should have all of your pressure drops responding directly to volume. Cold oil, high PSID, hot oil ..low PSID ..but it would always vary with the volume through it ..high or low.

True ... there will always be a pressure drop across a device that is resistant to flow, and the associated pressure drop will be proportional to the flow volume and fluid viscosity.

Originally Posted By: Gary Allan

You would still have to figure some way of having the filter reduce it's relative resistance while still dropping the supply across both. I'm not sure (haven't thought it out too far), but I think you would have to see the engine side (on my two gauge setup) dip assuming that you don't exceed the oil pump's relief capacity. Both must add up to supply, so any increase in PSID must reduce the drop across the engine. It would be very odd to see.

I can't think straight at the moment, but I think that this too would require more flow being shunted to the relief.

If the pump is in relief mode and viscosity constant, then of course any increase in filter PSID (due to loading, etc) will cause a decrease in the engine oil pressure reading (sensor after the filter). Ideally, if more flow was shunted out the relief valve to the sump, then there should be a corresponding drop in both filter PSID and engine oil pressure after the relief valve has stabilized the flow conditions.

One thing never discussed yet is how does the flow resistance of the filter and engine chance with thermal effects. In other words, does the filter and engine flow resistance change as they heat up? It’s entirely possible that the engine’s flow path becomes less restrictive as all the parts heat up and expand (ie, bearing clearances increase), which could dynamically change the flow resistance ratio of the filter/engine circuit. I can’t really see how an oil filter’s flow resistance would decrease as it heated up, but if it did, due to the element material “opening up”, you would also think it’s filtering performance might also change some (become worse) with its temperature.