Originally Posted By: oil_film_movies

There is energy conservation (and conversion) principles in physics, the biggest reference you seek, and there is a reference which explains the same thing I did:

"The principal method that causes the Helmholtz resonator to be effective is that the movement of air in the neck of the resonator causes a thermo-acoustic conversion of energy from acoustic sound to heat ...." --

http://pub.dega-akustik.de/IN2016/data/articles/000506.pdf which is specifically referring to the circular tire cavity noise issue here.

As I type, the acoustic energy from the keyboard that is lost on any physical mass is converted to heat. The concept is so basic that it's taken for granted. Reading the .pdf I'm getting an understanding of this fascination with damping ratios and the energy conversion associated with it, but it's my understanding the author mentioned it only to highlight the end of some of the energy's life as acoustic noise- the problem being solved for.

Originally Posted By: oil_film_movies

Not synonymous? There are unifying first principles at play here. (This is what makes an engineer see solutions, applying physics.) Basic energy-mass-stiffness-damping of Helmholtz resonators and Tuned Mass Dampers are indeed the same.

Sure, sure I agree, but they're definitely not synonymous. Not all Helmholtz cavities function as dampers and no other type of tuned-mass damping device uses exclusively a common gas as both the spring and the mass. No problem seeing the "unifying first principles" between the

specific use of a Helmholtz cavity for damping purposes vs other tuned-mass dampers of the general category. Also by definition, a resonator and damper are 180 degrees apart (if you will) in function.

Originally Posted By: oil_film_movies

Again, NOT cancellation inside the circular tire cavity. The abstract you quoted does not match the actual paper it refers to, probably written by a another person unfamiliar with what the original paper and author actually had working.

Any counter-phase resonance destructive to the source phase-frequency qualifies as cancellation, there is no minimum-degree or amplitude threshold that I'm aware of to qualify.

Also bear in mind that the computerized

active noise cancellation you're apparently reserving the term 'noise-cancellation' for, is only

more effectively noise-cancelling vs passive methods and yet, is never even perfect. In physical real-life, nothing rings perfectly.

Originally Posted By: oil_film_movies

You'd agree that the counter wave from the Helmholtz resonator must be 180 degrees out of phase to cancel the excitation wave, right?

I do not agree and did not say that.

Originally Posted By: oil_film_movies

Tire cavity acoustic waves excite the Helmholtz cavity at it's resonant frequency, which then absorbs the energy and converts it to heat.

Otherwise the acoustics would have been transmitted more through the suspension and surrounding air.

And that's also what happens! Aside from the noise that is lost through the mass-damping effect of the apparatus, the offending (target) frequency in this case 255Hz, is also simply shifted to less offensive frequencies, thus that portion of noise energy is not converted to heat

at that stage. As far as noise attenuation, this is the basic principle behind noise-shaping. Damping is clearly not the only means of noise attenuation in Helmholtz wheels.

From your reference document (refer to Fig 12 & 13):

"It can be seen that the amplitude at the resonance of 255Hz is reduced by approximately 15dB, by splitting that frequency into two adjascent smaller frequencies which are around dB lower in amplitude. The lower Doppler frequency is reduced by around 2dB due to the bandwidth of the Helmholtz resonator. While the tyre cavity sound pressure amplitude is reduced through the use of Helmholtz resonators, it creates many smaller resonances, at lower amplitudes"

Quote:

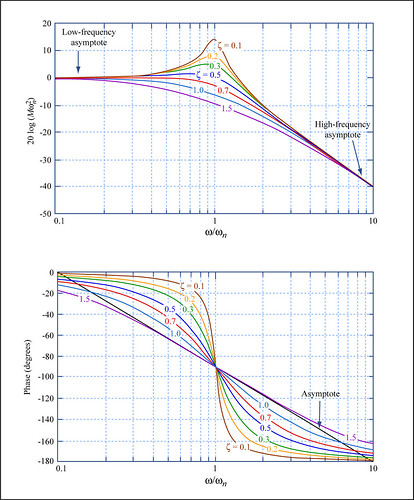

Note: The Helmholtz device damping (zeta) may be quite low, maybe around 0.05, so the peak would be even higher than the chart shows.

Sure. The mass of air in the the neck area is not so massive after all.