JHZR2

Staff member

When below 45F, and especially below freezing, my 91 BMW 318i has a lifter tick. Sounds like a sewing machine, and goes away after about two minutes of driving, during which I try to never go over 2000RPM.

I've tried a bunch of things - 0w oil, neutra, kreen, zmax, LM MoS2. All had some quieting behaviors, but none lasted.

So I'm just sticking with M1 10w-40.

But I have a few questions:

-I've heard lots of folks say that they've driven for years with a tick. I've also read that driving with a lifter that doesn't take the valves up properly is a recipe for a burned valve, since the valve will not be traveling its correct distance. Which is the case?

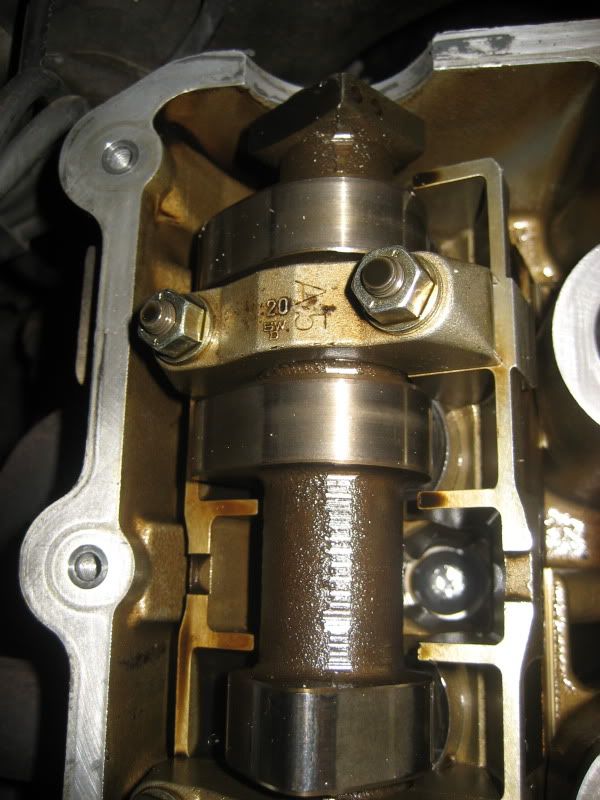

-Is it prudent to replace only one lifter (if you can find which one it is), or must you do all 16?

- How do you determine which is ticking?

-Does this job require removal of the head?

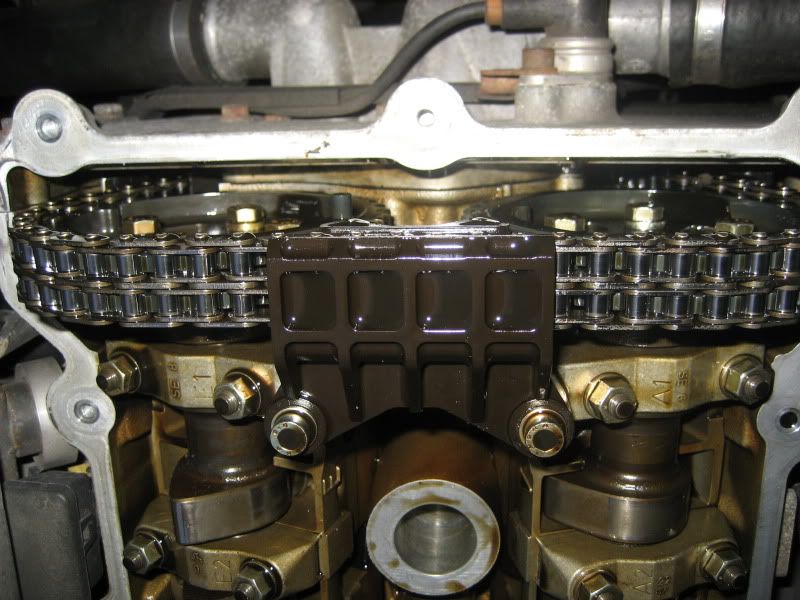

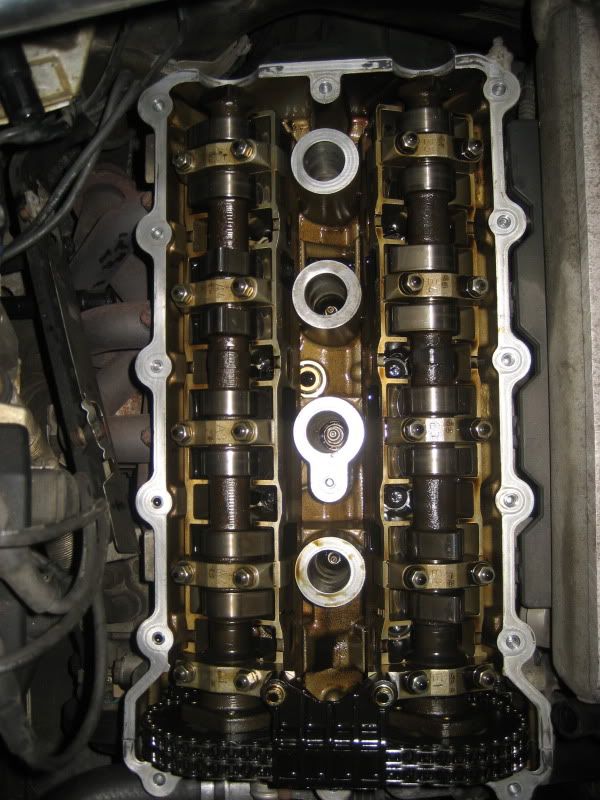

- is this job a DIY without special tools? Like remove the VC, unscrew the bearings holding the cams down, pull the cams, extract the lifters, then replace and torque down back together?

Thanks!

I've tried a bunch of things - 0w oil, neutra, kreen, zmax, LM MoS2. All had some quieting behaviors, but none lasted.

So I'm just sticking with M1 10w-40.

But I have a few questions:

-I've heard lots of folks say that they've driven for years with a tick. I've also read that driving with a lifter that doesn't take the valves up properly is a recipe for a burned valve, since the valve will not be traveling its correct distance. Which is the case?

-Is it prudent to replace only one lifter (if you can find which one it is), or must you do all 16?

- How do you determine which is ticking?

-Does this job require removal of the head?

- is this job a DIY without special tools? Like remove the VC, unscrew the bearings holding the cams down, pull the cams, extract the lifters, then replace and torque down back together?

Thanks!