This presentation shows a 20-40% reduction in friction and wear by adding Moly DTC, or "nanoparticles"

https://bobistheoilguy.com/forums/posts/1511442/

But the key to me is 20-40% reduction over what? If over bare bones dino, I can believe it. But I think for a well formulated oil with a strong additive package I don't think you can't say Moly is necessarily better because the chemists have balanced the ingredients to work together. For example, M1 0w40 uses small amounts of moly, shaeffers in moderate amounts, and redline high amounts (in some formulations).

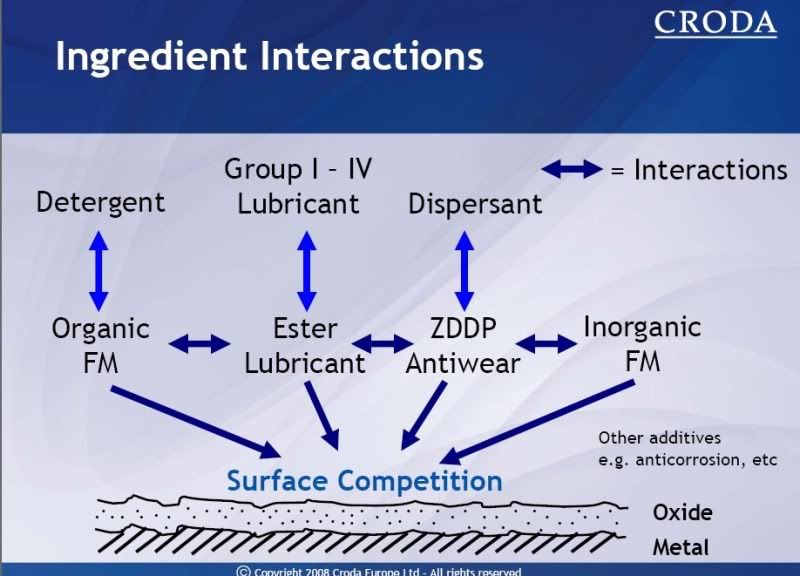

Some of these witches brews are amazingly complex and the ingredients are carefully balanced. So just adding a moly additive f.e. may be beneficial to one oil, say bare bones dino (I'm guessing here) but may not for another oil, say an oil like biosyn that uses antimony similarly to moly as I understand it, ZDDP, and even copper as additives. These additives are all in competition with each other. This CRODA slide illustrates this:

I hate to say it, but you almost have to have "faith" that the formulator knows what they are doing and there use of moly, or not, as part of their "pallete" of addtives they use in their own brew is the right thing for them based on the total package.

Another reason I think the different between oils is so small now is that the basic proportions of ZDDP to detergent etc. have all been worked out (and of course common req. by API etc.) and the "lowest" levels of oils nowadays is not that bad. The highest levels of oils are occupied by those oils where the chemists are really fine tuning and tweaking the additives, basestocks, and the complex interactions between them. These are my impressions based on my limited level of knowledge anyway.