I recently stumbled across some very interesting coolant research that directly pertains to some of the discussions that have been taking place here recently, I've attempted to summarize it:

Currently the US Army is using conventional green Inorganic Acid Technology (IAT) coolant with Supplemental Coolant Additive (SCA) and changing it annually instead of testing and recharging it. This is obviously quite expensive and wasteful, so they decided to look at moving to an Extended Life Coolant (ELC) that would be suitable for all the numerous different vehicles the Army fields.

They started by looking at all the engines used in ground vehicles and equipment, and what the manufacturers recommended ELC is:

https://apps.dtic.mil/sti/citations/AD1114771

Along side that they conducted a commercial market survey of available ELCs and their properties:

https://apps.dtic.mil/sti/citations/AD1112055

Five ELCs were selected for testing along side the existing conventional coolant; two that use straight Organic Acid Technology (OAT), two Hybrid OATs (HOAT), and one Nitrited OAT (NOAT).

All six were then subjected to laboratory bench and simulated service testing:

https://apps.dtic.mil/sti/citations/AD1170629

The commercial coolants were anonymized for confidentiality, but there's enough information present in the report to determine which is which:

The goal was not just to find a single coolant and select it for exclusive use, but to develop a specification that multiple products can be qualified as meeting. They want said specification to cover both light and heavy duty engines, so compatibility with cast aluminum parts commonly found in light duty engines is critical. And to make things harder qualified coolants must also be compatible with each other so they can be freely mixed in the field.

Therefor compatibility testing was under taken by mixing samples of each possible combination of the six candidates at ratios of 30/70, 50/50, and 70/30.

These blends were then subjected to ASTM D4340 testing for compatibility with cast aluminum alloys under heat-rejecting conditions; A cast aluminum test specimen with an alloy typical of that used in cylinder heads is exposed to coolant with salt (NaCl) added to it at a temperature of 135 °C (275 °F) and pressure of 193 kPa (28 psi) for one week. After which it's cleaned and measured to determine how much, if any, weight it lost, and what its condition is. The coolant is examined for its appearance and pH, and checked for the presence of any solids/precipitates.

The coolants they looked at generally claimed to be able to be safely mixed with other products, however of the 30 blends they tested 17 of them produced "large, white, jelly-fish like precipitates" and had heat-transfer corrosion rates above the allowable 1 mg per cm2 per week!

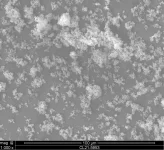

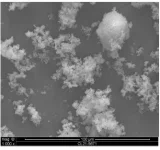

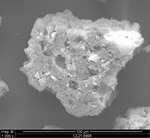

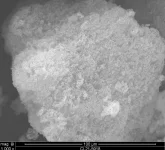

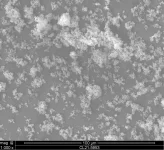

These precipitates were analyzed with a number of different methods including Scanning Electron Microscopy (SEM):

Energy Dispersive Spectroscopy (EDS) found the presence of aluminum in the precipitates, which did not come from the coolants.

The two OATs and the NOAT were the exception, they did not form any precipitates when mixed with each other. The rest of the testing on the precipitates was inconclusive.

There are a few other interesting tidbits in the report:

The two OAT coolants were selected to progress to real world testing as they were determined to be the most universal, it will be interesting to see how they do!

Currently the US Army is using conventional green Inorganic Acid Technology (IAT) coolant with Supplemental Coolant Additive (SCA) and changing it annually instead of testing and recharging it. This is obviously quite expensive and wasteful, so they decided to look at moving to an Extended Life Coolant (ELC) that would be suitable for all the numerous different vehicles the Army fields.

They started by looking at all the engines used in ground vehicles and equipment, and what the manufacturers recommended ELC is:

https://apps.dtic.mil/sti/citations/AD1114771

Along side that they conducted a commercial market survey of available ELCs and their properties:

https://apps.dtic.mil/sti/citations/AD1112055

Five ELCs were selected for testing along side the existing conventional coolant; two that use straight Organic Acid Technology (OAT), two Hybrid OATs (HOAT), and one Nitrited OAT (NOAT).

All six were then subjected to laboratory bench and simulated service testing:

https://apps.dtic.mil/sti/citations/AD1170629

The commercial coolants were anonymized for confidentiality, but there's enough information present in the report to determine which is which:

| Sample ID # | Product | Type | Color | Inorganic Additives |

| FL-18023-20 | Cummins ES Compleat | HOAT | Blue | Borate, Phosphate, Silicate, Nitrate, Nitrite and Molybdate |

| FL-18024-20 | Final Charge Global OAT Extended Life Coolant | OAT | Red | Nitrates, Molybdates |

| FL-18030-20 | Conventional CID A-A-52624 | IAT | Green | Nitrate, Nitrite, Borate, Silicate |

| FL-18031-20 | John Deere Cool-Gard II | HOAT | Orange | Borate, Phosphate, Molybdate, Nitrate, and Silicate |

| FL-18071-20 | Cat ELC | NOAT | Strawberry Red | Nitrites, Molybdates |

| FL-18072-20 | Cummins ES Compleat | OAT | Red | Nitrates, Molybdates |

The goal was not just to find a single coolant and select it for exclusive use, but to develop a specification that multiple products can be qualified as meeting. They want said specification to cover both light and heavy duty engines, so compatibility with cast aluminum parts commonly found in light duty engines is critical. And to make things harder qualified coolants must also be compatible with each other so they can be freely mixed in the field.

Therefor compatibility testing was under taken by mixing samples of each possible combination of the six candidates at ratios of 30/70, 50/50, and 70/30.

These blends were then subjected to ASTM D4340 testing for compatibility with cast aluminum alloys under heat-rejecting conditions; A cast aluminum test specimen with an alloy typical of that used in cylinder heads is exposed to coolant with salt (NaCl) added to it at a temperature of 135 °C (275 °F) and pressure of 193 kPa (28 psi) for one week. After which it's cleaned and measured to determine how much, if any, weight it lost, and what its condition is. The coolant is examined for its appearance and pH, and checked for the presence of any solids/precipitates.

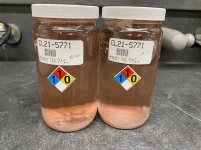

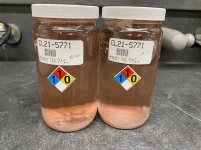

The coolants they looked at generally claimed to be able to be safely mixed with other products, however of the 30 blends they tested 17 of them produced "large, white, jelly-fish like precipitates" and had heat-transfer corrosion rates above the allowable 1 mg per cm2 per week!

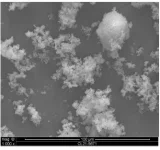

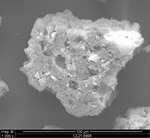

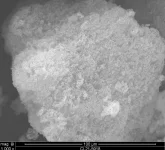

These precipitates were analyzed with a number of different methods including Scanning Electron Microscopy (SEM):

Energy Dispersive Spectroscopy (EDS) found the presence of aluminum in the precipitates, which did not come from the coolants.

The two OATs and the NOAT were the exception, they did not form any precipitates when mixed with each other. The rest of the testing on the precipitates was inconclusive.

There are a few other interesting tidbits in the report:

- OATs are noted to have very slightly higher thermal conductivity, potentially leading to very *slightly* increased cooling system efficiency, which could give a tiny increase in fuel economy.

- The engine OEMs they spoke to collectively agreed that 2-EHA is harmful should not be allowed.

- The OEMs additionally agreed that OAT coolant was the best fit for the Army's needs, NOAT was rejected for not being safe for use with aluminum.

The two OAT coolants were selected to progress to real world testing as they were determined to be the most universal, it will be interesting to see how they do!

Last edited by a moderator: