Yup, only threads should be lubed, not the cone face.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lug Nuts Seizing Up

- Thread starter George7941

- Start date

Good information! You're saying that the torque is generated by the face of the cone on the rim, rather than thread-on-thread, correct?First reason.

Probably you stretched the studs.

Second reason.

Bingo.

Why you shouldn't apply oil onto the cone? This reduces friction ONCE when tightening thus the same torque allows for a much higher tension. Half a year later? That oil is long gone and you feel the real tension and torque to break the nuts loose.

Just never do it. I'd bet GM recommends not to use a air gun withou limiter and not apply oil.

If you actually think you need it just apply some tiny bit of anti seize on the theads only.

.

And by implication, if there is significant friction between the threads, then the lug nut might be under-torqued as a result of not enough of the torque reading being contributed by friction between the cone and the rim. (My wording is awkward, but I hope makes sense.)

I do use a small bit of anti-seize on the threads, but not on the cones.

It’s a combination, but most people think only threads contribute to torque. The area under the head contributes greatly though. And if you have other materials under, like gaskets etc. that affects the torque as well.

- Joined

- Dec 4, 2021

- Messages

- 746

Interesting. I would have thought tension / bolt stretch would be more of a factor.It’s a combination, but most people think only threads contribute to torque. The area under the head contributes greatly though. And if you have other materials under, like gaskets etc. that affects the torque as well.

View attachment 130987

George7941

Thread starter

Just checked the owners' manual, it says not to apply any lubricant anywhere, so I will stop applying the oil to the cone face.

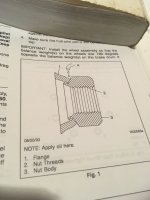

On the medium duty trucks I work on, they recommend oil at the end of the nut. See pic. But these are hub piloted wheels and have washered nuts. Looks like I should follow a different procedure for stud piloted wheels and not use oil.

There is not any significant rust or corrosion on the nuts and on the mating cone faces on the rim.

I will find out next spring if not lubricating the cone face leads to easier lug nut removal

On the medium duty trucks I work on, they recommend oil at the end of the nut. See pic. But these are hub piloted wheels and have washered nuts. Looks like I should follow a different procedure for stud piloted wheels and not use oil.

There is not any significant rust or corrosion on the nuts and on the mating cone faces on the rim.

I will find out next spring if not lubricating the cone face leads to easier lug nut removal

Attachments

Problem with that is you don’t know if it came loose or broke lol. Happened to me on a bolt (it broke)That's nothing. Your nuts ain't really tight until you need a 4 foot breaker bar PLUS a 5 foot cheater pipe.

View attachment 130910

Permatex recommends normal torque for bolts when using their AZ.It’s a combination, but most people think only threads contribute to torque. The area under the head contributes greatly though. And if you have other materials under, like gaskets etc. that affects the torque as well.

View attachment 130987

Can you provide the referance/source for the picture you provided?

Pretty easy to see the stud still in the nut to tell it's broken off if the missing stud alone isn't a clue.Problem with that is you don’t know if it came loose or broke lol. Happened to me on a bolt (it broke)

Permatex recommends normal torque for bolts when using their AZ.

Can you provide the referance/source for the picture you provided?

It’s a pretty good read

https://www.pcb.com/Contentstore/mk...Fastener-Design-and-Analysis-White-Paper).pdf

Wow. it sure is! Thank you.

- Joined

- Jan 5, 2021

- Messages

- 191

IMO you have a stretch problem,basically any bolt and nut combo that you can't reasonably finger tighten has a paint,rust,corrosion, cross thread or stretch problem.Your job is to try to figure it out the easy way.Try a different nut.They make thread chasers for your studs and lugs,sometimes its only a boogered up thread. When I bought my utility trailer I found individual chasers for studs and lugs,a few extra nuts,if your in rust belt like me,be real careful, especially with that torque gun

JHZR2

Staff member

Are the lug bolts/nuts the same for alloy and steel wheels?

I used to have this issue big time on my 91 BMW. The lug bolt seats were the same, but I found out the actual lug bolts were different. Anti seize didn’t help, oil/grease didn’t help. I even was accused on YouTube of putting my impact gun in forward mode vs reverse as the reason they wouldn’t come off. Ummm, no. Me needing to stand many feet away on the end of a cheater pipe was not tightening them up…. There was genuine chemical corrosion from whatever coating was/wasn’t there.

I used to have this issue big time on my 91 BMW. The lug bolt seats were the same, but I found out the actual lug bolts were different. Anti seize didn’t help, oil/grease didn’t help. I even was accused on YouTube of putting my impact gun in forward mode vs reverse as the reason they wouldn’t come off. Ummm, no. Me needing to stand many feet away on the end of a cheater pipe was not tightening them up…. There was genuine chemical corrosion from whatever coating was/wasn’t there.

I never had any trouble until with wheels sticking to hubs until I bought a '75 LTD wagon. Once I got the wheels off , I gave the mating pieces, hub and wheel, a thin coat of chassis lube. Stud threads too. I'm more concerned with getting a wheel off than I am about one falling off.

I always add a fro of oil to threads & taper seat then run them down lightly with impact. I then torque to spec or slightly less because of lubricant & I always make sure the nuts actually move & tighten to spec.

Putting a torque wrench on a nut & hearing it click without turning is not torquing, it is over tightened if it does not turn while torquing.

I’ve watched tire guys use torque sticks then a torque wrench to check with no additional turning of nut. It is already over torqued.

They get stuck on because of corrosion between the taper fit of the nut & wheels. Alloy wheels are particularly prone to this.

I use oil not neversieze because neversieze makes a mess & gets on everything.

90cummins

Putting a torque wrench on a nut & hearing it click without turning is not torquing, it is over tightened if it does not turn while torquing.

I’ve watched tire guys use torque sticks then a torque wrench to check with no additional turning of nut. It is already over torqued.

They get stuck on because of corrosion between the taper fit of the nut & wheels. Alloy wheels are particularly prone to this.

I use oil not neversieze because neversieze makes a mess & gets on everything.

90cummins

George7941

Thread starter

Careful with the oil on the taper seat. It ended up being why my lug nuts were so hard to loosen. Recommended torque is 140 ft lbs, I was using less and it still did not prevent the nuts from being overtightened. Last fall I left the taper seat dry and this spring the nuts came off without excessive force.I always add a fro of oil to threads & taper seat then run them down lightly with impact. I then torque to spec or slightly less because of lubricant & I always make sure the nuts actually move & tighten to spec.

Putting a torque wrench on a nut & hearing it click without turning is not torquing, it is over tightened if it does not turn while torquing.

I’ve watched tire guys use torque sticks then a torque wrench to check with no additional turning of nut. It is already over torqued.

They get stuck on because of corrosion between the taper fit of the nut & wheels. Alloy wheels are particularly prone to this.

I use oil not neversieze because neversieze makes a mess & gets on everything.

90cummins

Similar threads

- Replies

- 34

- Views

- 2K

- Replies

- 47

- Views

- 8K

- Replies

- 9

- Views

- 2K

- Replies

- 22

- Views

- 2K