I was thinking about my motorcycle the other day, which naturally led me to think about oil. My thought is, in certain use conditions it seems reasonable that the oil has sheared to a lower viscosity before additive depletion/exhaustion. In that case, determining the right service interval depends on first finding out how long an oil can stay in grade, then performing the hair-splitting analyses that we're so fond of.

From that, I began to see the utility in a cheap, crude viscometer.

Falling ball viscometer, Cole-Parmer, $180

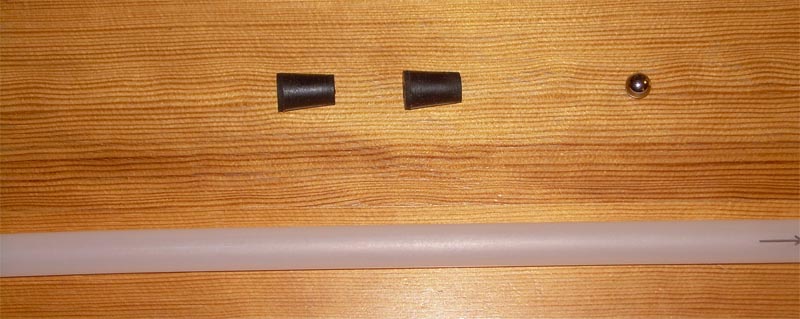

Falling ball viscometer, Homemade, $1.08

Fill with test fluid, toss in boiling water for a bit, then measure the elapsed time for the ball to fall a fixed distance. Use a couple of fluids of lesser and higher known viscosity to calibrate, then interpolate.

Anyone have experience with something like this? Care to share experience, or suggestions for calibration fluids?

From that, I began to see the utility in a cheap, crude viscometer.

Falling ball viscometer, Cole-Parmer, $180

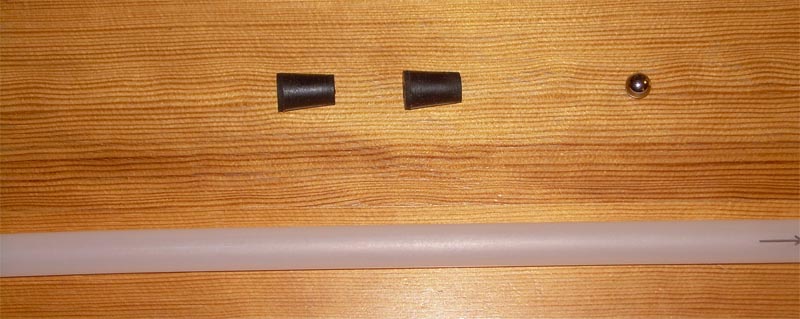

Falling ball viscometer, Homemade, $1.08

Fill with test fluid, toss in boiling water for a bit, then measure the elapsed time for the ball to fall a fixed distance. Use a couple of fluids of lesser and higher known viscosity to calibrate, then interpolate.

Anyone have experience with something like this? Care to share experience, or suggestions for calibration fluids?