JHZR2

Staff member

Because I’m on hour 4.5 waiting for a tow, I’ve started to think about how my fan clutch falling off came to be.

This is more a geometry/dynamic movement question regarding how fasteners back out, so I think it warrants its own thread.

I’m tired, hot, dehydrated, so I can’t visualize well.

What I know is this:

- it still was generally by the water pump, I guess the bolt for the pump was still in the bore of the water pump pulley slightly. It’s not like the fan flung all around underhood.

- maybe 25 miles before this, I felt like the engine was idling slightly low. No idea if this is related. Not sure I’d have found a loose fan anyway.

What I know about the fan is this:

- the engine turns clockwise if I look at it from the front. So right rotation

- the bolt that holds the fan in also is a right hand thread, right is tight.

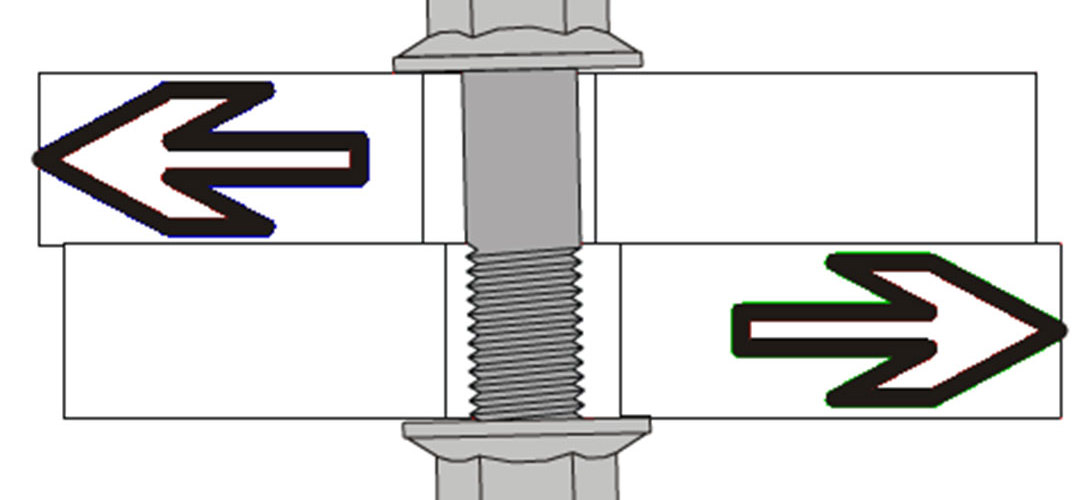

- The clutch is designed to turn… ccw???!? Note the arrow. Note that this side in the photo would be facing the front of the vehicle. The other side has a male end that inserts into the female socket of the water pump.

Could this item be entirely wrong? Was that why it was always on? I did drive it for maybe 500 miles or so before it came off. But if it wants to be spinning the other way, could that be the issue? I can’t see how that would cause the bearing in it to seize up tight, as I can’t spin it by hand.

But how could this happen? I’d suspect a stuck bearing might cause the whole thing to change speeds at a different rate than the engine during acceleration or deceleration, and ultimately cause the bolt to loosen? It is only an Allen bolt and isn’t torqued very tight. There’s limited space to do anything to even get it off.

So what could happen? I know it was installed and torqued correctly.

Thanks for your insights!

This is more a geometry/dynamic movement question regarding how fasteners back out, so I think it warrants its own thread.

I’m tired, hot, dehydrated, so I can’t visualize well.

What I know is this:

- it still was generally by the water pump, I guess the bolt for the pump was still in the bore of the water pump pulley slightly. It’s not like the fan flung all around underhood.

- maybe 25 miles before this, I felt like the engine was idling slightly low. No idea if this is related. Not sure I’d have found a loose fan anyway.

What I know about the fan is this:

- the engine turns clockwise if I look at it from the front. So right rotation

- the bolt that holds the fan in also is a right hand thread, right is tight.

- The clutch is designed to turn… ccw???!? Note the arrow. Note that this side in the photo would be facing the front of the vehicle. The other side has a male end that inserts into the female socket of the water pump.

Could this item be entirely wrong? Was that why it was always on? I did drive it for maybe 500 miles or so before it came off. But if it wants to be spinning the other way, could that be the issue? I can’t see how that would cause the bearing in it to seize up tight, as I can’t spin it by hand.

But how could this happen? I’d suspect a stuck bearing might cause the whole thing to change speeds at a different rate than the engine during acceleration or deceleration, and ultimately cause the bolt to loosen? It is only an Allen bolt and isn’t torqued very tight. There’s limited space to do anything to even get it off.

So what could happen? I know it was installed and torqued correctly.

Thanks for your insights!