If I may, I have some points of views on filtering. I know this is going to stir the pot so to speak with many high end filter users but that's the way I like it.

To start with, I have recently been looking into filtration and examining filtration in general.

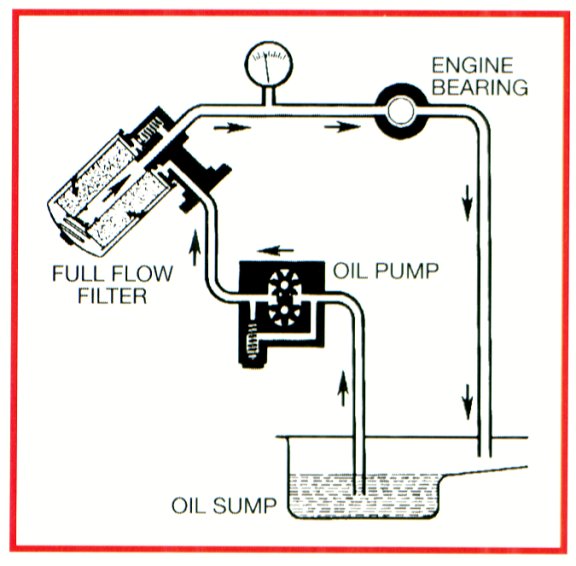

Here's a basic full flow filter diagram that demonstrates the path flow of oil through an engine. Notice that on the bottom, oil is pumped through the oil pump, which has a pressure(spring) on the bottom, which if too much pressure exists, it diverts it back around to the input side of the pump.

Now, onto the filter.. In this diagram, notice that the oil travels into the outer side of the media and inside of the filter can. On the bottom, it has a by pass valve spring, common in a lot of filters. Some by passes are on the top but either way, both work on the same principle.

OK, lets look at this... Oil pump produces anywhere from 30-60LBS of oil pressure, depending on pump design,engine,rpm and such. Given this, oil is pumped through to the outer side of the can. Lets say 40lbs of pressure is now on pushing inward on the filter media to go through and be filtered. Can a filter media allow 40lbs of oil pressure to pass through it at once? No, especially ones with higher filter media, which if media filters better, then it would stand to reason, there is more resistance to flow.(I'll prove this point later). Ok, so given that 40lbs of oil pressure can't flow through the media all at once, Now the bypass kicks in..

Lets take a moment to understand just exactly how does this work.. The by pass circuit has a spring calibrated to open between 8-12lbs say. So, if you have 40lbs of pressure on one side of the media(outer in this case) and with the media allowing say 20lbs through at a time(no real idea as to what it is but no way 40) you now have a difference of 20lbs between the inside of the media and the outside. Bingo, you've exceeded the 8-12lb limit thus it has opened. Now, If this was not to happen, that 40lbs of outer pressure pushing against the media, could in fact eventually crush or collapse the media inward. This is why you will see metal insides on filter medias so that it would not allow the media to crush and withstand higher amounts of pressure on the outside incase of a stuck by pass valve.

So, to keep the media from collapsing inward, you want to maintain equal pressure inside as outside. If the filter cannot pass 40lbs of pressure, then how does it keep 40lbs in the inside? The by pass has to stay open.

IMO, there is no way any filter media is going to allow the same amount of oil pressure on the outside into the inside without going into by pass. Filters are in the by pass mode most all the time as oppose to some of the time. Only when the the difference of pressure between the inside and the outside of the media are equal + or - the 8-12lb spring pressure would it be closed which would be intermittently on and off. Only part of the oil being pumped through is actually getting filtered and the rest passes through, and over a period of driving would all the oil eventually get filtered through.

Another point to consider here... The older an engine gets, the more flow is needed. Why? In the diagram, you'll notice that the engine bearing is where oil will meet resistance to flow and this is where pressure is developed to start with. The tighter the bearings, the less flow of oil, the more back pressure is produced on the inside side of the filter media. The older the engine with used bearings, the more clearance between the bearing and crank, the less resistance to flow, the lower the oil pressure on the inner media. So, if the oil pump is producing 40lbs of pressure on the outside of the filter media, but there is less resistance to flow through the bearings, the bigger the difference of oil pressure between the outside and the inside, the more the oil flows through the bypass to maintain equal pressure on the inside and outside media.

I'm going to continue in just a moment with more info about filter media.