This filter is my official "nail" in the Purolator "coffin".

This came off my Jeep, ran a gallon of RT6 and everything that had a splash left in containers. In went an equivalent Denso, and topped off with some PYB 10w30. Left the oil in as it was only in there for 2k miles, and the can was clean (couple specks in there). Oil/filter is/was in service for 18 months or so. Oil will stay there until I get some oil for it on sale, maybe...

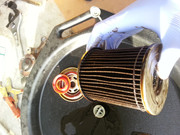

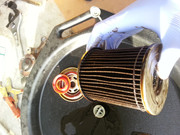

The filter came out internally flawless, ADBV/gasket had no rips, pliable (silicone). Pleats were perfect, which was a sigh of relief, but disappointing as I wasted an intact filter.

This came off my Jeep, ran a gallon of RT6 and everything that had a splash left in containers. In went an equivalent Denso, and topped off with some PYB 10w30. Left the oil in as it was only in there for 2k miles, and the can was clean (couple specks in there). Oil/filter is/was in service for 18 months or so. Oil will stay there until I get some oil for it on sale, maybe...

The filter came out internally flawless, ADBV/gasket had no rips, pliable (silicone). Pleats were perfect, which was a sigh of relief, but disappointing as I wasted an intact filter.