Results are likely the same because Schaeffer used viscosity grade readacross (VGRA) and baseoil interchange rules (BOI) to read one result (probably on a 5W-30) to the visc grades and baseoil mixes in the other products. Detailed in API 1509 appendix E and F.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Schaeffer Oil Seq. IIIG Results ALL the same? How?

- Thread starter CrawfishTails

- Start date

- Status

- Not open for further replies.

CrawfishTails

Thread starter

I've already asked about whether its possible to blend 5 oils to those exact results, and I instead get answers that sound like Dr. Phil on crack!

CrawfishTails

Thread starter

Originally Posted By: jfang

Results are likely the same because Schaeffer used viscosity grade readacross (VGRA) and baseoil interchange rules (BOI) to read one result (probably on a 5W-30) to the visc grades and baseoil mixes in the other products. Detailed in API 1509 appendix E and F.

Would that apply here if those are Seq IIIG test results?

Results are likely the same because Schaeffer used viscosity grade readacross (VGRA) and baseoil interchange rules (BOI) to read one result (probably on a 5W-30) to the visc grades and baseoil mixes in the other products. Detailed in API 1509 appendix E and F.

Would that apply here if those are Seq IIIG test results?

MolaKule

Staff member

Originally Posted By: CrawfishTails

I've already asked about whether its possible to blend 5 oils to those exact results, and I instead get answers that sound like Dr. Phil on crack!

Ya get away from that Lophophora williamsii.

It is possible to formulate to those exact results.

I've already asked about whether its possible to blend 5 oils to those exact results, and I instead get answers that sound like Dr. Phil on crack!

Ya get away from that Lophophora williamsii.

It is possible to formulate to those exact results.

Last edited:

dnewton3

Staff member

In regard to the testing results, it is first and foremost important to contact the OEM and ask for details.

I personally have contacted Schaeffer's in the past regarding some fuel economy claims they made, and they provided me detailed documents. Their facts seemed substantiated, but they were "biased" (shall we say) for the purpose of marketing. But as long as they have a disclaimer, and offer details, then they are in reasonable compliance and not some imagined FTC violation. Never confuse marketing slush with real testing results. Every company, including this one, will edit, compress, alter and align what they want to say outwardly to the public.

You can report it to the FTC if you want, but the first thing they will do is what you apparently want to skip over; they will ask Schaeffer's for a direct explanation before they condemn. Perhaps it was an error in transmission; perhaps an employee untrained; perhaps an interpretive viewpoint; perhaps a lab mistake; perhaps legitimate ...

Don't get wadded up before you seek a full explanation and sincerely listen to the answer.

Do the due-diligence. Then assess. Then make a conclusion.

I personally have contacted Schaeffer's in the past regarding some fuel economy claims they made, and they provided me detailed documents. Their facts seemed substantiated, but they were "biased" (shall we say) for the purpose of marketing. But as long as they have a disclaimer, and offer details, then they are in reasonable compliance and not some imagined FTC violation. Never confuse marketing slush with real testing results. Every company, including this one, will edit, compress, alter and align what they want to say outwardly to the public.

You can report it to the FTC if you want, but the first thing they will do is what you apparently want to skip over; they will ask Schaeffer's for a direct explanation before they condemn. Perhaps it was an error in transmission; perhaps an employee untrained; perhaps an interpretive viewpoint; perhaps a lab mistake; perhaps legitimate ...

Don't get wadded up before you seek a full explanation and sincerely listen to the answer.

Do the due-diligence. Then assess. Then make a conclusion.

Originally Posted By: jfang

Results are likely the same because Schaeffer used viscosity grade readacross (VGRA) and baseoil interchange rules (BOI) to read one result (probably on a 5W-30) to the visc grades and baseoil mixes in the other products. Detailed in API 1509 appendix E and F.

+1

Results are likely the same because Schaeffer used viscosity grade readacross (VGRA) and baseoil interchange rules (BOI) to read one result (probably on a 5W-30) to the visc grades and baseoil mixes in the other products. Detailed in API 1509 appendix E and F.

+1

CrawfishTails

Thread starter

Originally Posted By: CrawfishTails

Originally Posted By: jfang

Results are likely the same because Schaeffer used viscosity grade readacross (VGRA) and baseoil interchange rules (BOI) to read one result (probably on a 5W-30) to the visc grades and baseoil mixes in the other products. Detailed in API 1509 appendix E and F.

Would that apply here if those are Seq IIIG test results?

On that subject of baseoil interchange rules, the base oils span quite a range, as we're talking from Supreme 9000 full-syns: 0w-20, 5w-20, & 5w-30 on through Supreme 7000 semi-syns: 5w-30 & 10w-30 ... Thats 5 different oil blends, all having the exact same test results in 2 areas (visc increase and cam wear). Doubtful this is the culprit here.

Originally Posted By: badtlc

Why don't you research if cam wear is based more on additive package or base oil viscosity? If additive package is the driving factor in cam wear, this falls totally into the realm of believable.

Cam wear and viscosity increase during the IIIG (remember 2 areas of the IIIG test were identical for 5 blends) are very much a function of both visc & additives. Think about it, as boundary lubrication and near-boundary lubrication conditions occur on the surface of the lobes, viscosity governs oil film thickness and additives step in as various basestocks form different tribofilms in combination. Its both!

Originally Posted By: MolaKule

It is possible to formulate to those exact results.

Thank you. Its in the realm of possibility then. Still seems odd you could hit both visc increase & an exact 9.8 micron cam wear for all 5 oils, since the span of products is large. For example, its known to be tough to get a 0w-20 to have great cam wear, and lighter oils like that have different visc increases than a 5w-30 too. You get it. A lot of variables to juggle across 5 differing oils.

Another example, bobbydavro, a tribologist or engineer involved with Castrol recently made a comment on bitog to the effect of how difficult it was to get a ligher visc oil like 0w-20 to pass the tough euro ACEA RNT (RadioNuclideTechnique) cam-tappet wear test, similar to the IIIG, a hot test on a 90's Nissan SOHC 4 cylinder.

Armed with this little bit of knowledge about baseOil exchange rules and MolaKule's opinion that its possible (probable though??) a blender can make 5 different oils with identical (down to the decimal place of micron wear identical) and also hit an exact 130% visc increase in the IIIG across all 5 oils, ...... its now time to ask Scheaffer for an explanation and documentation of certified test results. I can now approach them knowint a little bit about what to ask for. ..... (For those who say those are simply 10 typos, existing for years, or who say wear tests don't matter, they're simply wrong or delusional.)

Originally Posted By: jfang

Results are likely the same because Schaeffer used viscosity grade readacross (VGRA) and baseoil interchange rules (BOI) to read one result (probably on a 5W-30) to the visc grades and baseoil mixes in the other products. Detailed in API 1509 appendix E and F.

Would that apply here if those are Seq IIIG test results?

On that subject of baseoil interchange rules, the base oils span quite a range, as we're talking from Supreme 9000 full-syns: 0w-20, 5w-20, & 5w-30 on through Supreme 7000 semi-syns: 5w-30 & 10w-30 ... Thats 5 different oil blends, all having the exact same test results in 2 areas (visc increase and cam wear). Doubtful this is the culprit here.

Originally Posted By: badtlc

Why don't you research if cam wear is based more on additive package or base oil viscosity? If additive package is the driving factor in cam wear, this falls totally into the realm of believable.

Cam wear and viscosity increase during the IIIG (remember 2 areas of the IIIG test were identical for 5 blends) are very much a function of both visc & additives. Think about it, as boundary lubrication and near-boundary lubrication conditions occur on the surface of the lobes, viscosity governs oil film thickness and additives step in as various basestocks form different tribofilms in combination. Its both!

Originally Posted By: MolaKule

It is possible to formulate to those exact results.

Thank you. Its in the realm of possibility then. Still seems odd you could hit both visc increase & an exact 9.8 micron cam wear for all 5 oils, since the span of products is large. For example, its known to be tough to get a 0w-20 to have great cam wear, and lighter oils like that have different visc increases than a 5w-30 too. You get it. A lot of variables to juggle across 5 differing oils.

Another example, bobbydavro, a tribologist or engineer involved with Castrol recently made a comment on bitog to the effect of how difficult it was to get a ligher visc oil like 0w-20 to pass the tough euro ACEA RNT (RadioNuclideTechnique) cam-tappet wear test, similar to the IIIG, a hot test on a 90's Nissan SOHC 4 cylinder.

Armed with this little bit of knowledge about baseOil exchange rules and MolaKule's opinion that its possible (probable though??) a blender can make 5 different oils with identical (down to the decimal place of micron wear identical) and also hit an exact 130% visc increase in the IIIG across all 5 oils, ...... its now time to ask Scheaffer for an explanation and documentation of certified test results. I can now approach them knowint a little bit about what to ask for. ..... (For those who say those are simply 10 typos, existing for years, or who say wear tests don't matter, they're simply wrong or delusional.)

CrawfishTails

Thread starter

Spoke to Schaeffer techline just now. Schaeffer is claiming baseOil interchange guidelines means they can take their best result across the entire range of engine oils and publish it. They won't say which oil actually scored that well, as 9.8 microns is pretty good, at least compared to the very good Kendall GT-1, the other data point available.

So now I guess Pennzoil can claim PYB passes all the Ferrari tests since one synth oil they make does... hee-hee

So now I guess Pennzoil can claim PYB passes all the Ferrari tests since one synth oil they make does... hee-hee

Originally Posted By: CrawfishTails

So now I guess Pennzoil can claim PYB passes all the Ferrari tests since one synth oil they make does... hee-hee

of course pennzoil can do that if ferrari has baseoil interchange guidelines. why couldn't they?

So now I guess Pennzoil can claim PYB passes all the Ferrari tests since one synth oil they make does... hee-hee

of course pennzoil can do that if ferrari has baseoil interchange guidelines. why couldn't they?

Originally Posted By: CrawfishTails

Spoke to Schaeffer techline just now. Schaeffer is claiming baseOil interchange guidelines means they can take their best result across the entire range of engine oils and publish it. They won't say which oil actually scored that well, as 9.8 microns is pretty good, at least compared to the very good Kendall GT-1, the other data point available.

So now I guess Pennzoil can claim PYB passes all the Ferrari tests since one synth oil they make does... hee-hee

Nope, there's an Appendix R that can be applied also...the "Single Technology Matrix".

I just posted it in the BOI thread.

Allows one DI package to cross certify a bunch of oils after some testing is done...It's in all likelihood why Penrite in Oz seem to only have one additive package for everything...(well they have a different one for 30s and 16s, commensurate with the P limits)...their PDS other than that are all similar...as are their claims.

Spoke to Schaeffer techline just now. Schaeffer is claiming baseOil interchange guidelines means they can take their best result across the entire range of engine oils and publish it. They won't say which oil actually scored that well, as 9.8 microns is pretty good, at least compared to the very good Kendall GT-1, the other data point available.

So now I guess Pennzoil can claim PYB passes all the Ferrari tests since one synth oil they make does... hee-hee

Nope, there's an Appendix R that can be applied also...the "Single Technology Matrix".

I just posted it in the BOI thread.

Allows one DI package to cross certify a bunch of oils after some testing is done...It's in all likelihood why Penrite in Oz seem to only have one additive package for everything...(well they have a different one for 30s and 16s, commensurate with the P limits)...their PDS other than that are all similar...as are their claims.

CrawfishTails

Thread starter

OK, definition of "DI package":

"An acronym for Detergent Inhibitor package, this thick dark fluid is a concentrated cocktail containing most of the performance additives needed to formulate an oil. DI packs are generally made by additive companies...." (from this BITOG website)....

"An acronym for Detergent Inhibitor package, this thick dark fluid is a concentrated cocktail containing most of the performance additives needed to formulate an oil. DI packs are generally made by additive companies...." (from this BITOG website)....

CrawfishTails

Thread starter

Originally Posted By: Shannow

Originally Posted By: CrawfishTails

Spoke to Schaeffer techline just now. Schaeffer is claiming baseOil interchange guidelines means they can take their best result across the entire range of engine oils and publish it. They won't say which oil actually scored that well, as 9.8 microns is pretty good, at least compared to the very good Kendall GT-1, the other data point available.

So now I guess Pennzoil can claim PYB passes all the Ferrari tests since one synth oil they make does... hee-hee

Nope, there's an Appendix R that can be applied also...the "Single Technology Matrix".

I just posted it in the BOI thread.

Allows one DI package to cross certify a bunch of oils after some testing is done...It's in all likelihood why Penrite in Oz seem to only have one additive package for everything...(well they have a different one for 30s and 16s, commensurate with the P limits)...their PDS other than that are all similar...as are their claims.

Just seems not right to assume actual cam wear and visc increase in IIIG tests are gonna be the same, precisely the same 9.8 microns & 130% increase. I might be in over my head here. As we know as engineers, wear rates are sensitive to viscosity, additive concentrations and of course additive types, how much VI is there, all different when we're talking about 0w-20, 5w-20, 5w-30, full-syns and part-syns, 5 oils in all.

Interesting discussion though.

Originally Posted By: CrawfishTails

Spoke to Schaeffer techline just now. Schaeffer is claiming baseOil interchange guidelines means they can take their best result across the entire range of engine oils and publish it. They won't say which oil actually scored that well, as 9.8 microns is pretty good, at least compared to the very good Kendall GT-1, the other data point available.

So now I guess Pennzoil can claim PYB passes all the Ferrari tests since one synth oil they make does... hee-hee

Nope, there's an Appendix R that can be applied also...the "Single Technology Matrix".

I just posted it in the BOI thread.

Allows one DI package to cross certify a bunch of oils after some testing is done...It's in all likelihood why Penrite in Oz seem to only have one additive package for everything...(well they have a different one for 30s and 16s, commensurate with the P limits)...their PDS other than that are all similar...as are their claims.

Just seems not right to assume actual cam wear and visc increase in IIIG tests are gonna be the same, precisely the same 9.8 microns & 130% increase. I might be in over my head here. As we know as engineers, wear rates are sensitive to viscosity, additive concentrations and of course additive types, how much VI is there, all different when we're talking about 0w-20, 5w-20, 5w-30, full-syns and part-syns, 5 oils in all.

Interesting discussion though.

Originally Posted By: CrawfishTails

OK, definition of "DI package":

"An acronym for Detergent Inhibitor package, this thick dark fluid is a concentrated cocktail containing most of the performance additives needed to formulate an oil. DI packs are generally made by additive companies...." (from this BITOG website)....

Yeah, sorry...additive package then...

http://www.api.org/certification-programs/engine-oil-diesel-exhaust-fluid/~/media/files/certification/engine-oil-diesel/forms/application-part-q.ashx

Sort of information that goes in certification/cross reference.

OK, definition of "DI package":

"An acronym for Detergent Inhibitor package, this thick dark fluid is a concentrated cocktail containing most of the performance additives needed to formulate an oil. DI packs are generally made by additive companies...." (from this BITOG website)....

Yeah, sorry...additive package then...

http://www.api.org/certification-programs/engine-oil-diesel-exhaust-fluid/~/media/files/certification/engine-oil-diesel/forms/application-part-q.ashx

Sort of information that goes in certification/cross reference.

CrawfishTails

Thread starter

(Posting this over in the discussion of Base Oil Interchange rules and STM Single Tech Matrix guidelines too.) Its applicable to what I was trying to figure out was going on at Schaeffer Oil's tech data sheets here claiming exact 9.8 & 130% scores identically for all their motor oils. Still think this is fishy practice. Below, I think there is a valid reason for an oil company to only be able to say "PASS" if using STM with no actual engine tests, not exact figures! ---->

From http://papers.sae.org/2002-01-2676/ :

"Once a guideline is approved, a supplier can interchange or read an engine test pass for a particular additive package in a particular base oil and/or viscosity grade to a base oil and/or viscosity grade of equal or better performance without running an engine test."

OK, so it sounds like a company can only claim an oil they didn't actually run through a Sequence IIIG for example "passed", not the "all its oils magically" have the same micron wear rating and viscosity increases.

From http://papers.sae.org/2002-01-2676/ :

"Once a guideline is approved, a supplier can interchange or read an engine test pass for a particular additive package in a particular base oil and/or viscosity grade to a base oil and/or viscosity grade of equal or better performance without running an engine test."

OK, so it sounds like a company can only claim an oil they didn't actually run through a Sequence IIIG for example "passed", not the "all its oils magically" have the same micron wear rating and viscosity increases.

CrawfishTails

Thread starter

Originally Posted By: Nightmare

http://www.pqiamerica.com/March2013PCMO/schaeffersyn.htm The 309 ppm of moly is impressive.....

True that, Schaeffer Oil is kind of interesting. Notice high moly, high antimony, high sodium, high silcon, all of which suggests they have a slightly different approach than most other oils. Moly and antimony are anti-wear (noting an absence of boron), and sodium compounds are mostly detergent, with I believe anti-wear benefits too. Complicated, but choice of additives is cool.

One might say we can be reasonably sure Supreme 9000 5w-30 is the one that got the 9.8 and 130% result in IIIG, both great results, and the other oils were merely assumed to get that based on missapplication of STM.

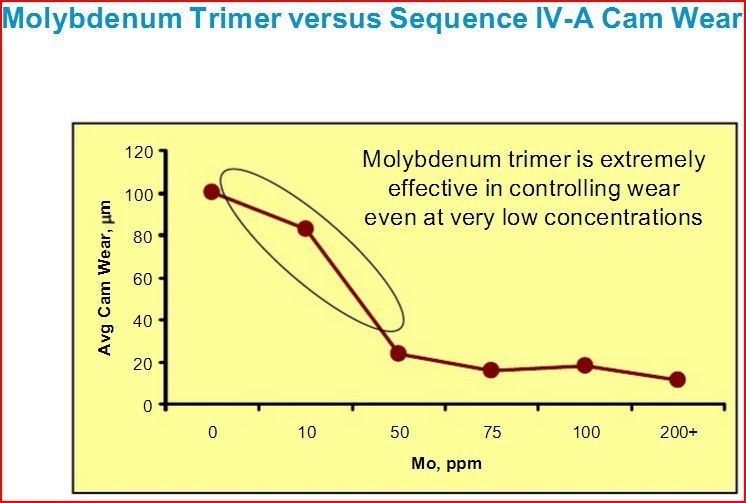

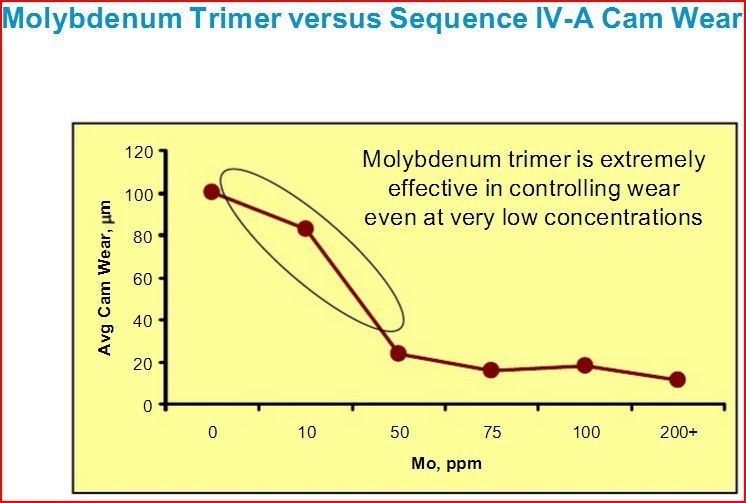

Might add that Schaeffer likely does NOT use the far more effective tri-nuclear moly that Infineum doles out to Mobil, Pennz, Quaker State, and Shell oils. The tri-nuc moly is about 2 or 3 times as effective, so when Pennz Ultra 0w-40 has 241 ppm tri-nuc moly, that is the real whopper for moly, not Schaeffer's 309 ppm of an older technology moly.

http://www.pqiamerica.com/March2013PCMO/schaeffersyn.htm The 309 ppm of moly is impressive.....

True that, Schaeffer Oil is kind of interesting. Notice high moly, high antimony, high sodium, high silcon, all of which suggests they have a slightly different approach than most other oils. Moly and antimony are anti-wear (noting an absence of boron), and sodium compounds are mostly detergent, with I believe anti-wear benefits too. Complicated, but choice of additives is cool.

One might say we can be reasonably sure Supreme 9000 5w-30 is the one that got the 9.8 and 130% result in IIIG, both great results, and the other oils were merely assumed to get that based on missapplication of STM.

Might add that Schaeffer likely does NOT use the far more effective tri-nuclear moly that Infineum doles out to Mobil, Pennz, Quaker State, and Shell oils. The tri-nuc moly is about 2 or 3 times as effective, so when Pennz Ultra 0w-40 has 241 ppm tri-nuc moly, that is the real whopper for moly, not Schaeffer's 309 ppm of an older technology moly.

Last edited:

Originally Posted By: CrawfishTails

The tri-nuc moly is about 2 or 3 times as effective, so when Pennz Ultra 0w-40 has 241 ppm tri-nuc moly, that is the real whopper for moly, not Schaeffer's 309 ppm of an older technology moly.

2 or 3 times as effective, please explain...and no schaeffers does not use the tri nuc moly

The tri-nuc moly is about 2 or 3 times as effective, so when Pennz Ultra 0w-40 has 241 ppm tri-nuc moly, that is the real whopper for moly, not Schaeffer's 309 ppm of an older technology moly.

2 or 3 times as effective, please explain...and no schaeffers does not use the tri nuc moly

CrawfishTails

Thread starter

Originally Posted By: salesrep

Originally Posted By: CrawfishTails

The tri-nuc moly is about 2 or 3 times as effective, so when Pennz Ultra 0w-40 has 241 ppm tri-nuc moly, that is the real whopper for moly, not Schaeffer's 309 ppm of an older technology moly.

2 or 3 times as effective, please explain...and no schaeffers does not use the tri nuc moly

OK. See http://www.readbag.com/infineum-document...-tribology-2009 and also

See http://www.bobistheoilguy.com/forums/ubbthreads.php?ubb=showflat&Number=3024485

and from an Infineum (Shell-Mobil moly supplier) presentation:

http://www.bobistheoilguy.com/forums/ubbthreads.php?ubb=showflat&Number=2265014

http://www.bobistheoilguy.com/forums/ubbthreads.php?ubb=showflat&Number=2265014

Originally Posted By: CrawfishTails

The tri-nuc moly is about 2 or 3 times as effective, so when Pennz Ultra 0w-40 has 241 ppm tri-nuc moly, that is the real whopper for moly, not Schaeffer's 309 ppm of an older technology moly.

2 or 3 times as effective, please explain...and no schaeffers does not use the tri nuc moly

OK. See http://www.readbag.com/infineum-document...-tribology-2009 and also

See http://www.bobistheoilguy.com/forums/ubbthreads.php?ubb=showflat&Number=3024485

and from an Infineum (Shell-Mobil moly supplier) presentation:

Last edited:

Originally Posted By: CrawfishTails

Originally Posted By: MolaKule

Originally Posted By: CrawfishTails

Originally Posted By: MolaKule

You have some interesting and divergent expectations.

Can I expect more from you? Something substantive perhaps? Are you a tribologist or not?

You've had great contributions in the past.

Are you really an engineer or are you trying to sustain an inane argument?

Mola's got his panties in a bunch!

Originally Posted By: CrawfishTails

Mola, either answer the question, discuss, or don't post. Easy.

A far fetched as it may seem, I've seen this type of argument before.

Originally Posted By: MolaKule

Originally Posted By: CrawfishTails

Originally Posted By: MolaKule

You have some interesting and divergent expectations.

Can I expect more from you? Something substantive perhaps? Are you a tribologist or not?

You've had great contributions in the past.

Are you really an engineer or are you trying to sustain an inane argument?

Mola's got his panties in a bunch!

Originally Posted By: CrawfishTails

Mola, either answer the question, discuss, or don't post. Easy.

A far fetched as it may seem, I've seen this type of argument before.

- Status

- Not open for further replies.

Similar threads

- Replies

- 5

- Views

- 3K

- Locked

- Replies

- 26

- Views

- 5K

- Locked

- Replies

- 77

- Views

- 45K

- Locked

- Replies

- 111

- Views

- 79K

- Replies

- 14

- Views

- 13K