Good luck. Allow for ventilation if working with PVC glue and primer. Etc. The primer especially.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mending plastic

- Thread starter JHZR2

- Start date

- Status

- Not open for further replies.

There is Loctite 1363118 (epoxy meant for plastic). I've used it... works well. Home Depot carries it.

There's also J-B Weld 8237 PlasticWeld, which I haven't tried before.

There's also J-B Weld 8237 PlasticWeld, which I haven't tried before.

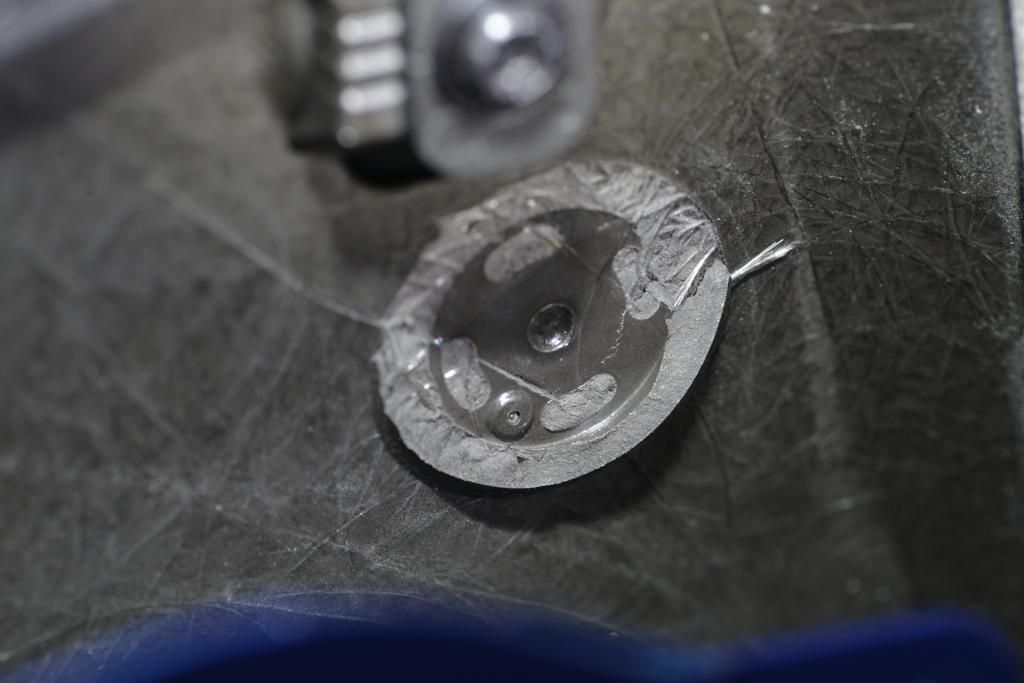

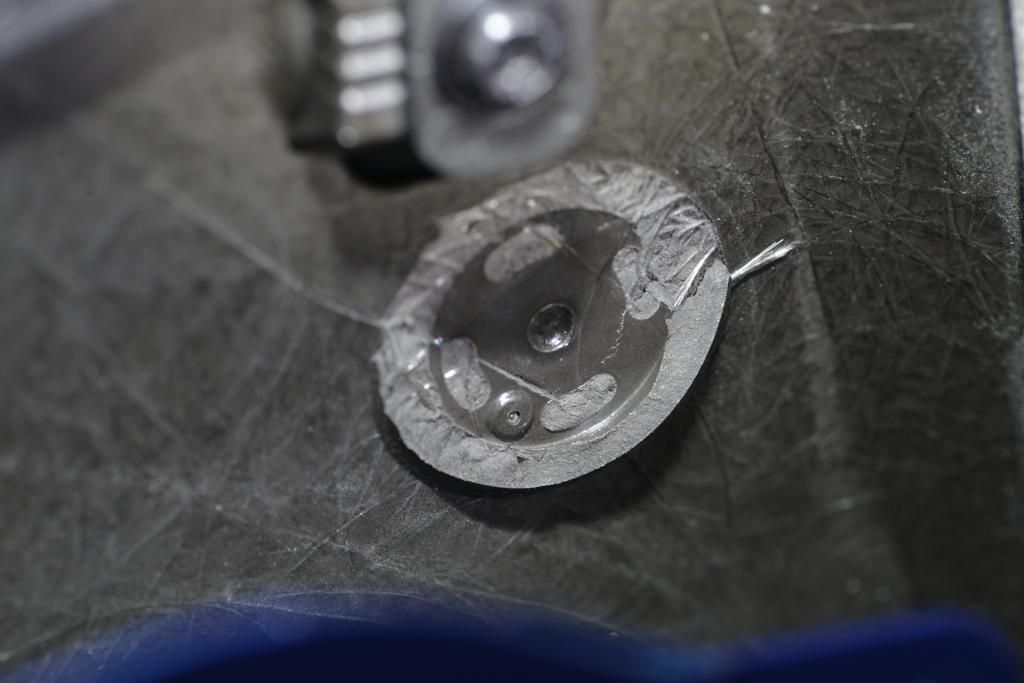

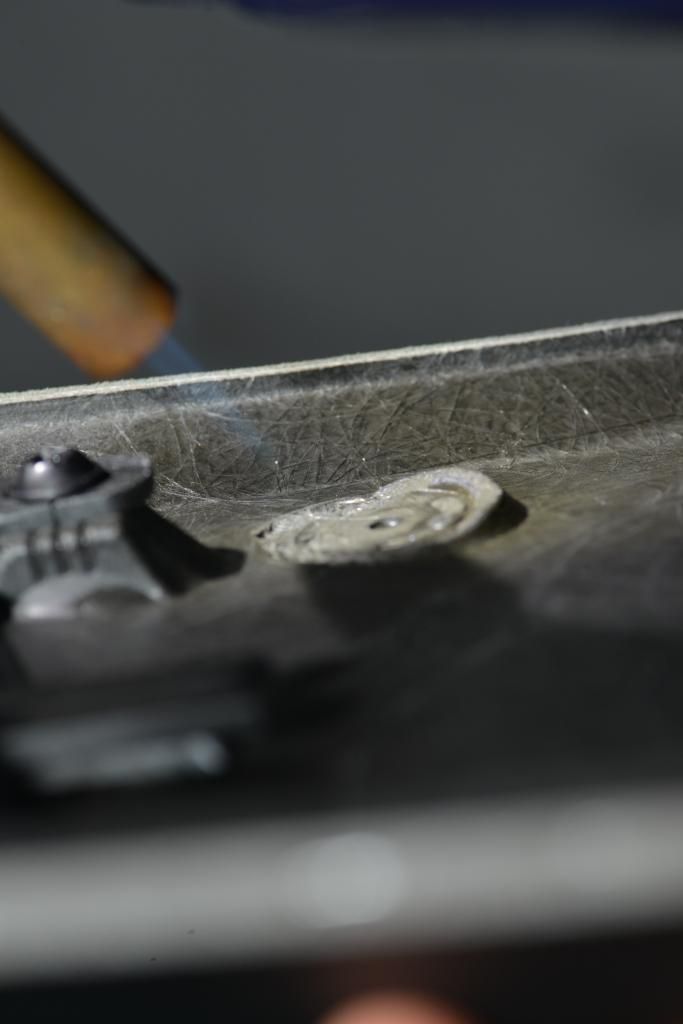

Probably the most important image... PE/PP mix then?

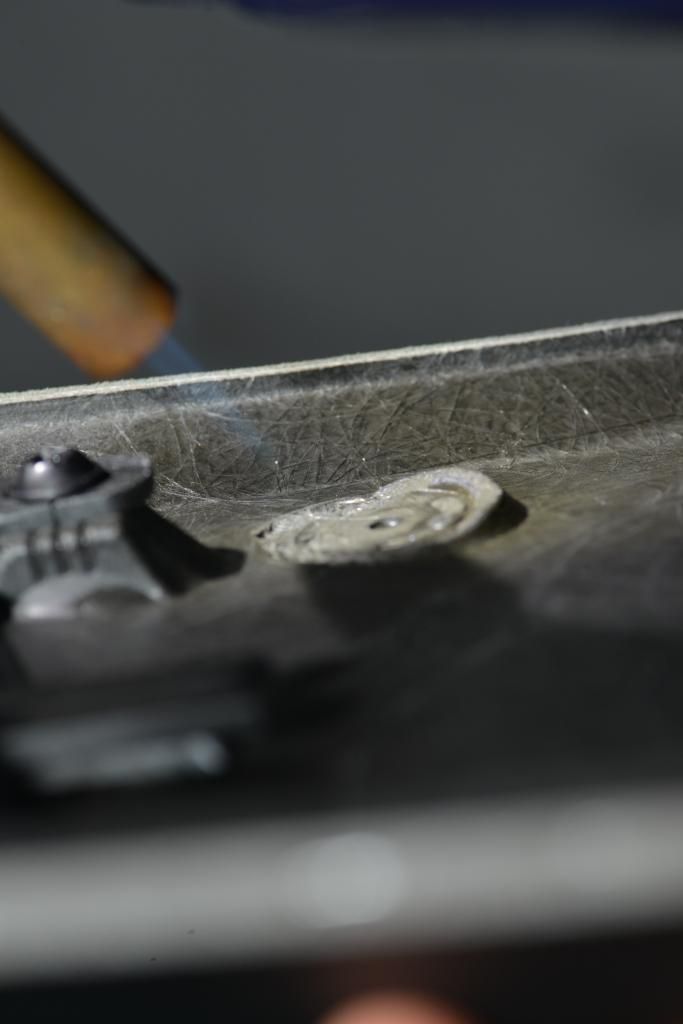

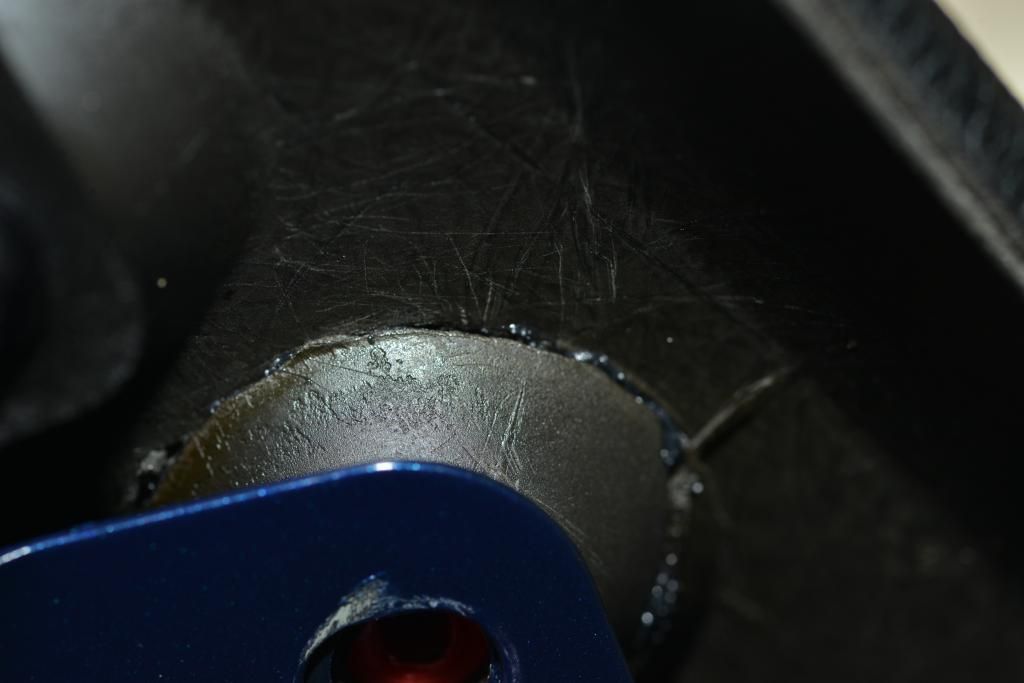

Seems glass reinforced. Decent surface for bonding on this side:

Obviously the red thing doesn't bond well. I think the item is screwed into, not a threaded rod. That's probably good from a torque basis. Notionally I can push it down to provide support when I finish screwing and torque goes up.

Thoughts??

Seems glass reinforced. Decent surface for bonding on this side:

Obviously the red thing doesn't bond well. I think the item is screwed into, not a threaded rod. That's probably good from a torque basis. Notionally I can push it down to provide support when I finish screwing and torque goes up.

Thoughts??

Yep, understood. You don't think scuff and flame/alcohol prep on the red thing and the area it contacts? What's nice is the rest of the area acts as a filet I guess...

I don't think you'll need it. But knock yourself out if you want to scuff up the center portion.

Flaming alcohol prep? That's a bit much. It's not a French dessert.

Perhaps just a light wipe down with isopropyl if you think there's contamination that will affect adhesion.

Flaming alcohol prep? That's a bit much. It's not a French dessert.

Perhaps just a light wipe down with isopropyl if you think there's contamination that will affect adhesion.

Google Q-Bond; I have it and I am absolutely impressed with it. I fixed broken tripod and a Cuisinart food processor. I had tried whole bunch of different glues and epoxies before but nothing worked in the high stress situation. Do you know the inter locking tab on a typical food processor? I used the glue to grow a new locking tab to the bowl! About $15 shipped from Amazon. Give it a try before trying anything else or worse giving up and buying new from BMW. http://www.amazon.com/gp/product/B002XF4S6C

You don't have to guess what it is, PP GF30 is polypropylene glass filled 30%

Originally Posted By: tom slick

You don't have to guess what it is, PP GF30 is polypropylene glass filled 30%

That's it?

Zoomed in a bit...

>PP+GF30/TPE

??? Different meaning? Seems PP is tougher to bond...

You don't have to guess what it is, PP GF30 is polypropylene glass filled 30%

That's it?

Zoomed in a bit...

>PP+GF30/TPE

??? Different meaning? Seems PP is tougher to bond...

PP IS harder to bond.

While I was poking a little fun above, I don't recommend corona flashing the bond area with the part still installed on the vehicle, as that is high risk if something goes amiss.

If you take the part off the vehicle, once it's on the bench you have all your repair options available.

I overlooked the convertible/wind shear factor in my earlier observation.

Because it's a convertible, it's in a very different environment than in an enclosed vehicle. I would also factor in if this fastener and part are going to be subjected to any wind shear forces when in motion. If they are, then I would much more strongly lean towards part replacement.

And the more I look at the fastening scheme of that trim panel, the more I believe it is a higher load fastener point that broke. On our R129s boot cover trim, it has at least 10 screws holding it down. It looks like this one has only 2 along the leading corners.

Repairing a high load fastener point is going to require more sophistication and taking the part off, IMO. And you're always going to run the risk that if the bond ever fails while underway and it lifts, it may wind sail and tear the entire panel right off, potentially damaging other parts of the car. The remaining pop fasteners won't hold that piece down. Neither will any other non-mechanical fastener at that point.

With that much repair labor already underway, just slap on a new part and have peace of mind.

The only other repair that would assure a secure result is going to involve drilling through the top, which will mar the part's appearance.

While I was poking a little fun above, I don't recommend corona flashing the bond area with the part still installed on the vehicle, as that is high risk if something goes amiss.

If you take the part off the vehicle, once it's on the bench you have all your repair options available.

I overlooked the convertible/wind shear factor in my earlier observation.

Because it's a convertible, it's in a very different environment than in an enclosed vehicle. I would also factor in if this fastener and part are going to be subjected to any wind shear forces when in motion. If they are, then I would much more strongly lean towards part replacement.

And the more I look at the fastening scheme of that trim panel, the more I believe it is a higher load fastener point that broke. On our R129s boot cover trim, it has at least 10 screws holding it down. It looks like this one has only 2 along the leading corners.

Repairing a high load fastener point is going to require more sophistication and taking the part off, IMO. And you're always going to run the risk that if the bond ever fails while underway and it lifts, it may wind sail and tear the entire panel right off, potentially damaging other parts of the car. The remaining pop fasteners won't hold that piece down. Neither will any other non-mechanical fastener at that point.

With that much repair labor already underway, just slap on a new part and have peace of mind.

The only other repair that would assure a secure result is going to involve drilling through the top, which will mar the part's appearance.

Last edited:

TPE is Thermo Plastic Elastomer: The plastics hhave a flex additive.

Originally Posted By: tom slick

TPE is Thermo Plastic Elastomer: The plastics hhave a flex additive.

BLAST!

Drove up to McMaster Carr today to buy some 3M 8005, which is designed for bonding PP. Will still sand, alcohol wipe and flame lick as I think these are best practices...

TPE is Thermo Plastic Elastomer: The plastics hhave a flex additive.

BLAST!

Drove up to McMaster Carr today to buy some 3M 8005, which is designed for bonding PP. Will still sand, alcohol wipe and flame lick as I think these are best practices...

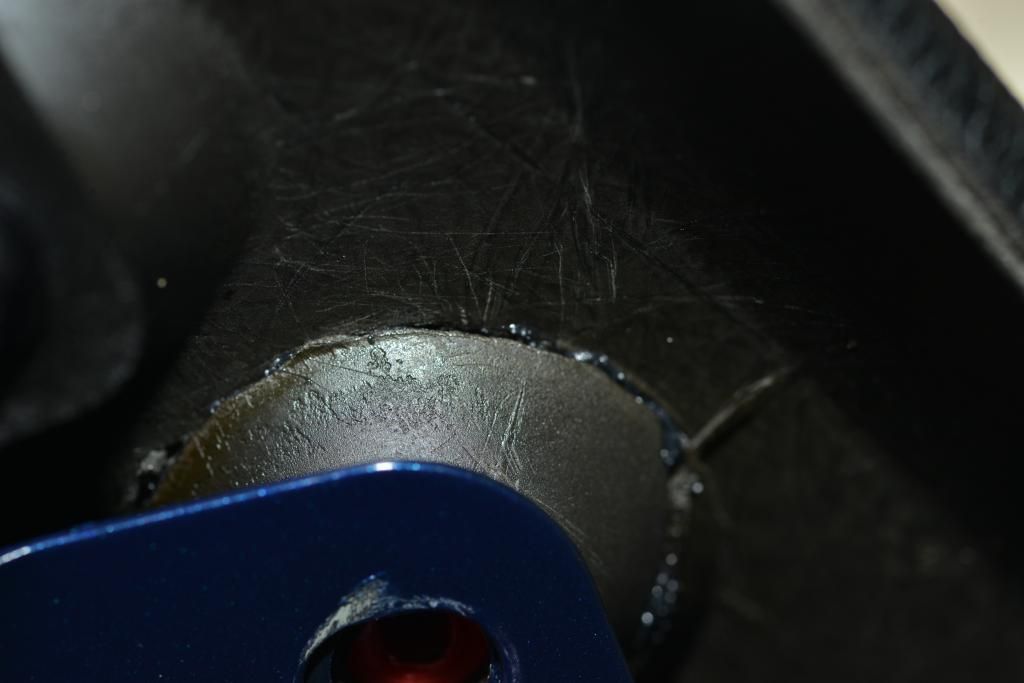

Well, its stuck. Almost had a heart attack when I was going to loosen the part to get it free and the trunk and top wouldn't budge. Turns out I had been fiddling too much with the top down and I guess the hydraulics had lost pressure. I had to lift the top into place, and then was able to get it to go to full open, then I was ok to move it again to an intermediate spot to work...

Not sure how great the job went... Did the alcohol and the flame (almost started the small broken piece on fire!), and then mixed the epoxy, waited for it for a bit (says three minute workability, so I waited nearly three minutes, then affixed the parts. Held them them clamped them for the night.

Not sure how great the job went... Did the alcohol and the flame (almost started the small broken piece on fire!), and then mixed the epoxy, waited for it for a bit (says three minute workability, so I waited nearly three minutes, then affixed the parts. Held them them clamped them for the night.

Well here is my repair process...

This was the part to be bonded originally...

And recall that this was the other side:

So I scuffed with 100 grit paper... I had 60 and 100, though I've seen 80 recommended. So I went with 100 to get more surface area.

I wiped it with denatured alcohol and then flame licked the parts.

Be aware that its pretty easy to get the parts to start to burn. I almost had that!

i drove to McMaster Carr yesterday to buy the proper 3M stuff. Its the only stuff Ive seen out there truly recommended for PP. It was a $32 tube, so a fairly costly gamble for a $245 part, but the highest chance of success IMO.

It is gritty stuff. Didn't look at the MSDS but Id guess it is silica or something similar. Fairly large particles for doing small gaps, but Im sure they optimized it...

Instructions say max strength after 12 hours at 77F, so I left it a good deal longer then that, then installed the part back onto the car.

Screwed it down without any issue and it seems to be holding just fine.

The 3M stuff is interesting. It has a very high holding strength on low surface energy plastics like PP, but it also is not cured as hard as I thought it would. I was expecting a very solid hard plastic structure, but there was still some give and softness to this cured pile of product that I had mixed.

Its stinky stuff, and they recommend just dripping some out before the quantity you want to use. Even that had somewhat self-mixed and begun to cure.

I may turn all this into a DIY.

So far, so good...

This was the part to be bonded originally...

And recall that this was the other side:

So I scuffed with 100 grit paper... I had 60 and 100, though I've seen 80 recommended. So I went with 100 to get more surface area.

I wiped it with denatured alcohol and then flame licked the parts.

Be aware that its pretty easy to get the parts to start to burn. I almost had that!

i drove to McMaster Carr yesterday to buy the proper 3M stuff. Its the only stuff Ive seen out there truly recommended for PP. It was a $32 tube, so a fairly costly gamble for a $245 part, but the highest chance of success IMO.

It is gritty stuff. Didn't look at the MSDS but Id guess it is silica or something similar. Fairly large particles for doing small gaps, but Im sure they optimized it...

Instructions say max strength after 12 hours at 77F, so I left it a good deal longer then that, then installed the part back onto the car.

Screwed it down without any issue and it seems to be holding just fine.

The 3M stuff is interesting. It has a very high holding strength on low surface energy plastics like PP, but it also is not cured as hard as I thought it would. I was expecting a very solid hard plastic structure, but there was still some give and softness to this cured pile of product that I had mixed.

Its stinky stuff, and they recommend just dripping some out before the quantity you want to use. Even that had somewhat self-mixed and begun to cure.

I may turn all this into a DIY.

So far, so good...

Good luck. It'll be interesting to see how this holds up with hot/cold delta-T's and vibration. Keep us posted.

- Status

- Not open for further replies.

Similar threads

- Replies

- 3

- Views

- 266

- Replies

- 5

- Views

- 726

- Replies

- 6

- Views

- 1K

- Replies

- 6

- Views

- 1K