JHZR2

Staff member

Hi,

I'm putting crown moulding in multiple rooms in my house. One of the rooms I'm using bigger moulding, like 3.5+". Because the house is somewhat crooked and the walls are all plaster, I'd like to put up nailing strips.

I don't have a table saw, just a circular saw and a compound mitre.

So there are instructions on this old house for how to make nailing strips.

http://www.thisoldhouse.com/toh/m/skill-builder/0,,20168434,00.html

But it isn't very clear how to cut the 2x4. I need to rip them with my circular saw.

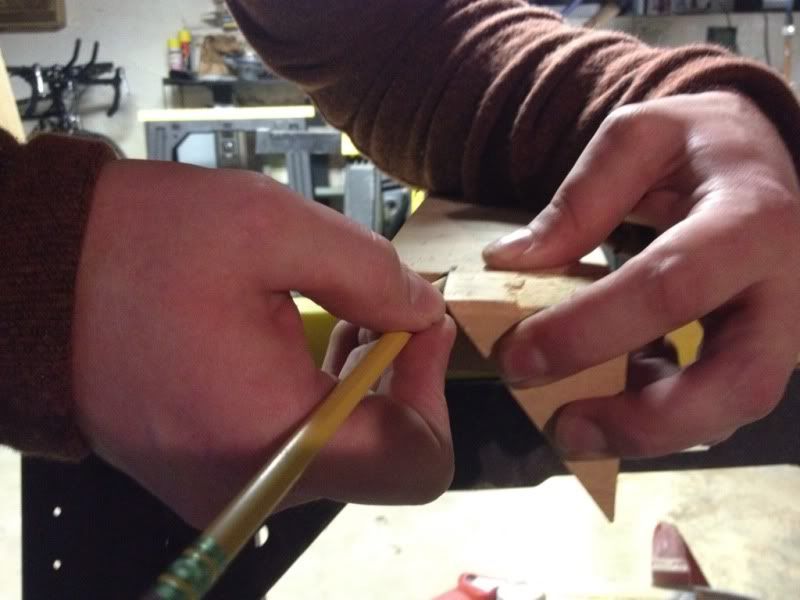

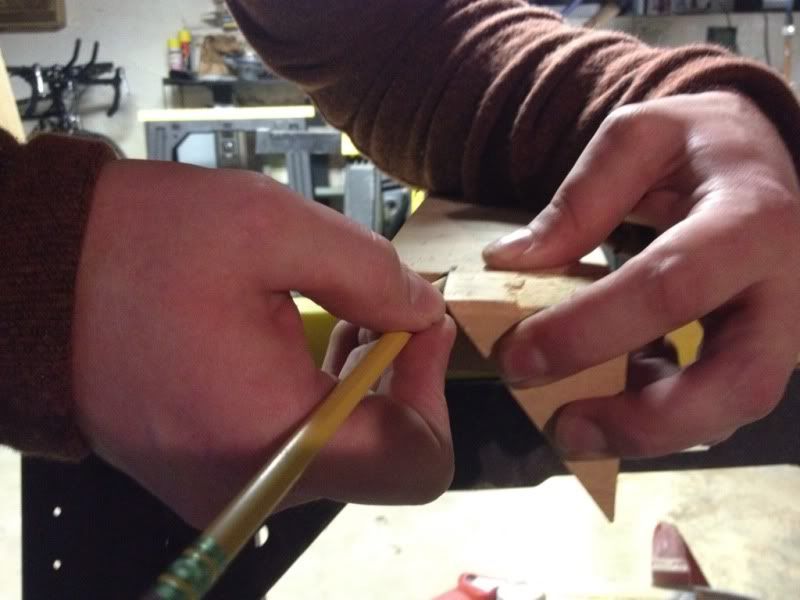

I tried the method I'm going to show, it works. Would love a safety critique though, as I'm far from a regular at ripping wood or operating a circular saw. I have a few 1000# saw horses, so I clamped the wood to the horses, scribed the lines on the wood, then cut.

So it is a 3-sawhorse setup. Clamp to two with someone spotting down there. Set the third horse a little but in and start ripping. Go a few inches in, change the horse to the end of the board, keep ripping in. Can only do about 5 of 8 feet, but to me it is safe, I have good control, and stay alongside the board at a good height.

Is there a better way?

Thanks!

I'm putting crown moulding in multiple rooms in my house. One of the rooms I'm using bigger moulding, like 3.5+". Because the house is somewhat crooked and the walls are all plaster, I'd like to put up nailing strips.

I don't have a table saw, just a circular saw and a compound mitre.

So there are instructions on this old house for how to make nailing strips.

http://www.thisoldhouse.com/toh/m/skill-builder/0,,20168434,00.html

But it isn't very clear how to cut the 2x4. I need to rip them with my circular saw.

I tried the method I'm going to show, it works. Would love a safety critique though, as I'm far from a regular at ripping wood or operating a circular saw. I have a few 1000# saw horses, so I clamped the wood to the horses, scribed the lines on the wood, then cut.

So it is a 3-sawhorse setup. Clamp to two with someone spotting down there. Set the third horse a little but in and start ripping. Go a few inches in, change the horse to the end of the board, keep ripping in. Can only do about 5 of 8 feet, but to me it is safe, I have good control, and stay alongside the board at a good height.

Is there a better way?

Thanks!