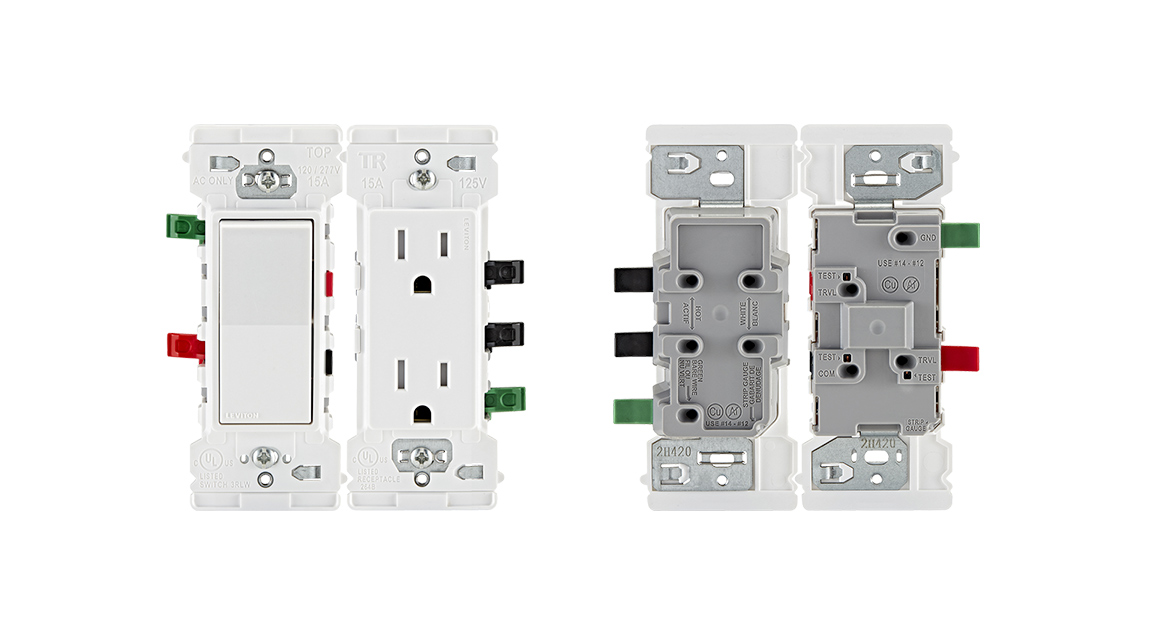

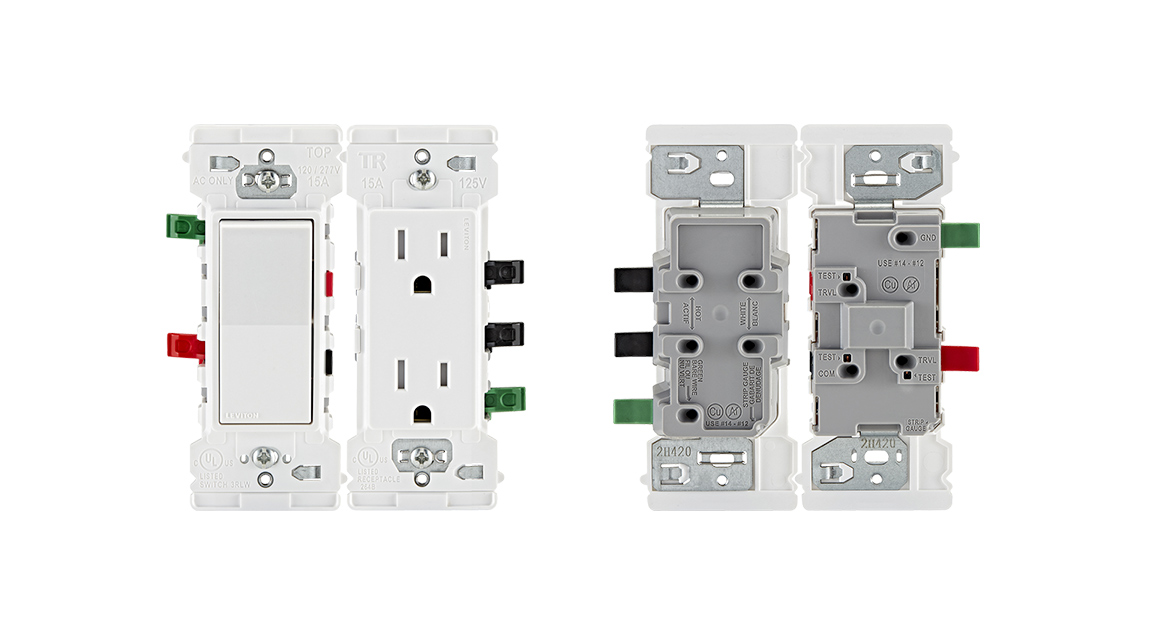

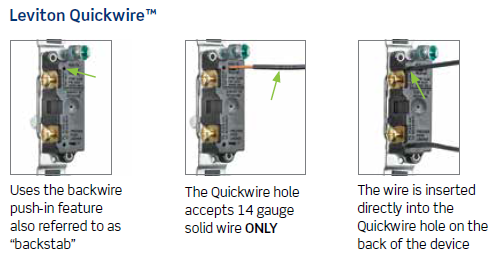

You’re referring to backstabs? Leviton calls theirs’ “QuickWire”.

I’ve looked inside a few, and there’s typically a curved depression for the wire to rest against, then a leaf spring/barb (that also serves as the release) that presses the inserted wire against the depression. As long as there’s decent pressure from the leaf spring, there should be fairly decent contact. The problem seems to be how good brass is long term as a leaf spring, and that it seems to weaken after several years, hot/cold cycles, and just the wire being in there for years. I’ve taken several out or at least switched to the screws after almost 30 years. The spring is definitely not as effective after that length of time. The spring has definitely been deformed after that amount of time.

I’m not sure about everything that WAGO makes, since that includes push in connectors. However, the 221 Lever-Nut uses a tinned copper bus bar and a steel spring at each lever position, along with some sort of barb to lock in wires. I’m guessing that’s what Leviton puts in. Maybe also Ideal with its In-Sure L2, which is a lever style connector where the lever is on the opposite side.

Just ordered a jar of 500 from Amazon since they were so cheap ($26). The price is mind boggling - cheaper than high quality wire nuts. I’m probably going to redo some of my work done with 3-port WAGO Lever-Nuts since I didn’t really need 3-port but I got them thinking they’d be more versatile. I do have one where I’m bridging connections in the box and then tapping a receptacle, but others there’s one port empty. I figure they can be reused.

I like the idea of using lever connectors instead of wire cuts for extensions. If there’s only a few inches, I don’t want to chew up what little wire there is to work with with a wire nut or a push in connector that can be removed with a bit of twisting that will obvious scratch up the wire.