- Joined

- Sep 26, 2010

- Messages

- 9,807

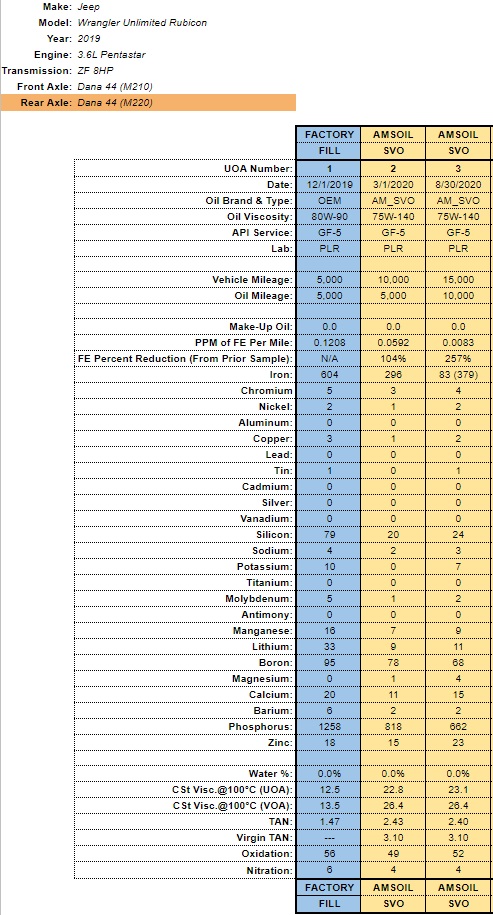

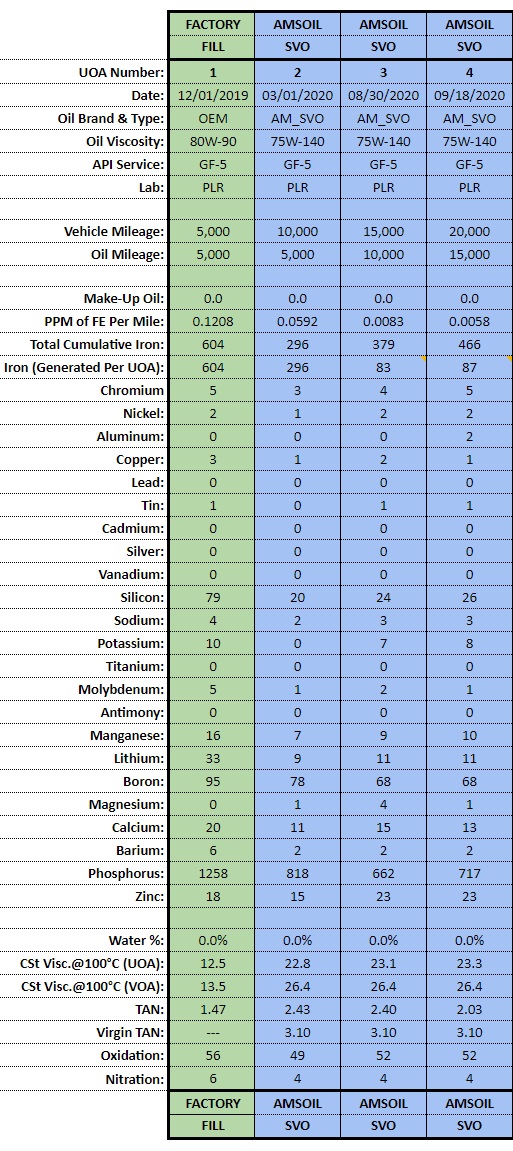

Here are the UOA results from Polaris for the Dana 44 front and rear axles of my Rubicon (M210 Front and M220 Rear). The viscosity of the oil indicates the factory fill was 80W-90 in both. I would have expected the rear to have 75W-140 in it since I have the towing package and Jeep recommends that oil for towing.

Although I have not used 4x4 mode yet, the front axle had some iron in the oil simply due to the design where the axle shafts spin in 4x2 mode, but the ring and pinion do not. The front axles on the Rubicon have a disconnect built-into them.

I have to say the UOA for the rear axle is the worst I have ever seen with regards to PPM of iron for such low mileage. For only 5,000 miles, it was a surprise to see 604PPM of iron. To put it into context, the cumulative iron for 150,000 miles in my 2010 FX4 (which had towed 8-9K pounds for at least 60,000 of those miles in temperatures ranging from -22°F to +117°F in the desert and mountains) was 697PPM of iron. With that said, these results support the concept that most axle wear occurs at 15K miles or less and it seems the Dana axle is no different.

The oil was fairly acidic with a TAN in the 1.47 to 1.81 range, but without a VOA of the oil to use as a comparison, it will not be possible to know if this is abnormal. However, most gear oil is somewhat acidic, for example, a VOA of Amsoil 75W-140 I performed found the TAN of the oil to be 3.1. As shown in this thread - 2019 Jeep Rubicon Axle OC [5,000 Miles], I picked up a second set of OEM front and rear covers from a fellow Jeep enthusiast and welded in a 1/8" NPT threaded boss into the top of the cover so that I can install a set of ISS Pro temperature gauges to monitor axle temperatures.

Viscosities for both oils are within specification and nothing else abnormal jumped out at me. I will be keeping an eye on the iron and may perform another UOA in a few thousand miles to ensure the iron is trending downwards as should be expected. 1.3QTs of Amsoil 75W-110 was installed in the front axle and 1.5QTs of Amsoil 75W-140 was installed in the rear. I will certainly not be performing any extended oil changes with the small capacity of these axles.

Enjoy!

![[Linked Image from iili.io] [Linked Image from iili.io]](https://iili.io/HujA21.jpg)

![[Linked Image from iili.io] [Linked Image from iili.io]](https://iili.io/HujTrP.jpg)

Although I have not used 4x4 mode yet, the front axle had some iron in the oil simply due to the design where the axle shafts spin in 4x2 mode, but the ring and pinion do not. The front axles on the Rubicon have a disconnect built-into them.

I have to say the UOA for the rear axle is the worst I have ever seen with regards to PPM of iron for such low mileage. For only 5,000 miles, it was a surprise to see 604PPM of iron. To put it into context, the cumulative iron for 150,000 miles in my 2010 FX4 (which had towed 8-9K pounds for at least 60,000 of those miles in temperatures ranging from -22°F to +117°F in the desert and mountains) was 697PPM of iron. With that said, these results support the concept that most axle wear occurs at 15K miles or less and it seems the Dana axle is no different.

The oil was fairly acidic with a TAN in the 1.47 to 1.81 range, but without a VOA of the oil to use as a comparison, it will not be possible to know if this is abnormal. However, most gear oil is somewhat acidic, for example, a VOA of Amsoil 75W-140 I performed found the TAN of the oil to be 3.1. As shown in this thread - 2019 Jeep Rubicon Axle OC [5,000 Miles], I picked up a second set of OEM front and rear covers from a fellow Jeep enthusiast and welded in a 1/8" NPT threaded boss into the top of the cover so that I can install a set of ISS Pro temperature gauges to monitor axle temperatures.

Viscosities for both oils are within specification and nothing else abnormal jumped out at me. I will be keeping an eye on the iron and may perform another UOA in a few thousand miles to ensure the iron is trending downwards as should be expected. 1.3QTs of Amsoil 75W-110 was installed in the front axle and 1.5QTs of Amsoil 75W-140 was installed in the rear. I will certainly not be performing any extended oil changes with the small capacity of these axles.

Enjoy!

![[Linked Image from iili.io] [Linked Image from iili.io]](https://iili.io/HujA21.jpg)

![[Linked Image from iili.io] [Linked Image from iili.io]](https://iili.io/HujTrP.jpg)