Great news, my girlfriend's 02 honda civic (LX with steel pan and actual gasket) isn't burning as much oil as I thought. The oil pan gasket has failed. I'll be replacing it with a new OEM gasket in the next few days... Should I use some sort of threadlocker on the bolts? (Obviously will be torquing to proper specs)

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oil pan bolts... Threadlocker?

- Thread starter Indyvwhonda

- Start date

- Status

- Not open for further replies.

JHZR2

Staff member

I don't recall any fsm I have saying to do so. Have you looked at a Honda service manual?

No.

Originally Posted By: OneEyeJack

No.

+1

No.

+1

All I would add is to make sure the threads on the block and the threads on the bolts are clean. I am that weird person that sends a thread chaser through bolt holes.

Sometimes you need to re-torque the pan bolts after the gasket settles and you can't do that if you got Loctite on there. Besides that, you probably wouldn't be able to get the threads clean enough anyway.

I can understand the thought process but that's just asking for trouble. It would probably interfere with an accurate reading when torquing them down.

- Joined

- Oct 28, 2014

- Messages

- 1,187

Originally Posted By: bdcardinal

All I would add is to make sure the threads on the block and the threads on the bolts are clean. I am that weird person that sends a thread chaser through bolt holes.

^^Yep; that's me. When I R & R anything on my cars, I don't care if it is an intake, exhaust, valve covers, oil pan, anything...I'm not a grease monkey being paid for how much I get done in an hour, I'm a diligent BITOGER and I'm proudly OCD...I chase threads and run a die down over bolts...Clean up the threads and use either aluminum or copper anti-seize, (Exhaust), clay based thread sealant, (intake), or mild lock tite (valve covers); or a dab of silicone. Use factory torque specs and don't do anything twice.

Edit: And nothing past the eighties has cork gaskets that need re-torque...There are valid reasons that AISC does not accept torque values...Torque CAN be a measurement of debris on the threads...If you don't know what AISC is...G-O-O-G-L-E.

All I would add is to make sure the threads on the block and the threads on the bolts are clean. I am that weird person that sends a thread chaser through bolt holes.

^^Yep; that's me. When I R & R anything on my cars, I don't care if it is an intake, exhaust, valve covers, oil pan, anything...I'm not a grease monkey being paid for how much I get done in an hour, I'm a diligent BITOGER and I'm proudly OCD...I chase threads and run a die down over bolts...Clean up the threads and use either aluminum or copper anti-seize, (Exhaust), clay based thread sealant, (intake), or mild lock tite (valve covers); or a dab of silicone. Use factory torque specs and don't do anything twice.

Edit: And nothing past the eighties has cork gaskets that need re-torque...There are valid reasons that AISC does not accept torque values...Torque CAN be a measurement of debris on the threads...If you don't know what AISC is...G-O-O-G-L-E.

Originally Posted By: Ihatetochangeoil

Originally Posted By: bdcardinal

All I would add is to make sure the threads on the block and the threads on the bolts are clean. I am that weird person that sends a thread chaser through bolt holes.

^^Yep; that's me. When I R & R anything on my cars, I don't care if it is an intake, exhaust, valve covers, oil pan, anything...I'm not a grease monkey being paid for how much I get done in an hour, I'm a diligent BITOGER and I'm proudly OCD...I chase threads and run a die down over bolts...Clean up the threads and use either aluminum or copper anti-seize, (Exhaust), clay based thread sealant, (intake), or mild lock tite (valve covers); or a dab of silicone. Use factory torque specs and don't do anything twice.

Edit: And nothing past the eighties has cork gaskets that need re-torque...There are valid reasons that AISC does not accept torque values...Torque CAN be a measurement of debris on the threads...If you don't know what AISC is...G-O-O-G-L-E.

Just be careful as to which bolts you run a die over. Cut into the root of a thread and change the minor diameter you'll find yourself with a much weaker bolt.

Originally Posted By: bdcardinal

All I would add is to make sure the threads on the block and the threads on the bolts are clean. I am that weird person that sends a thread chaser through bolt holes.

^^Yep; that's me. When I R & R anything on my cars, I don't care if it is an intake, exhaust, valve covers, oil pan, anything...I'm not a grease monkey being paid for how much I get done in an hour, I'm a diligent BITOGER and I'm proudly OCD...I chase threads and run a die down over bolts...Clean up the threads and use either aluminum or copper anti-seize, (Exhaust), clay based thread sealant, (intake), or mild lock tite (valve covers); or a dab of silicone. Use factory torque specs and don't do anything twice.

Edit: And nothing past the eighties has cork gaskets that need re-torque...There are valid reasons that AISC does not accept torque values...Torque CAN be a measurement of debris on the threads...If you don't know what AISC is...G-O-O-G-L-E.

Just be careful as to which bolts you run a die over. Cut into the root of a thread and change the minor diameter you'll find yourself with a much weaker bolt.

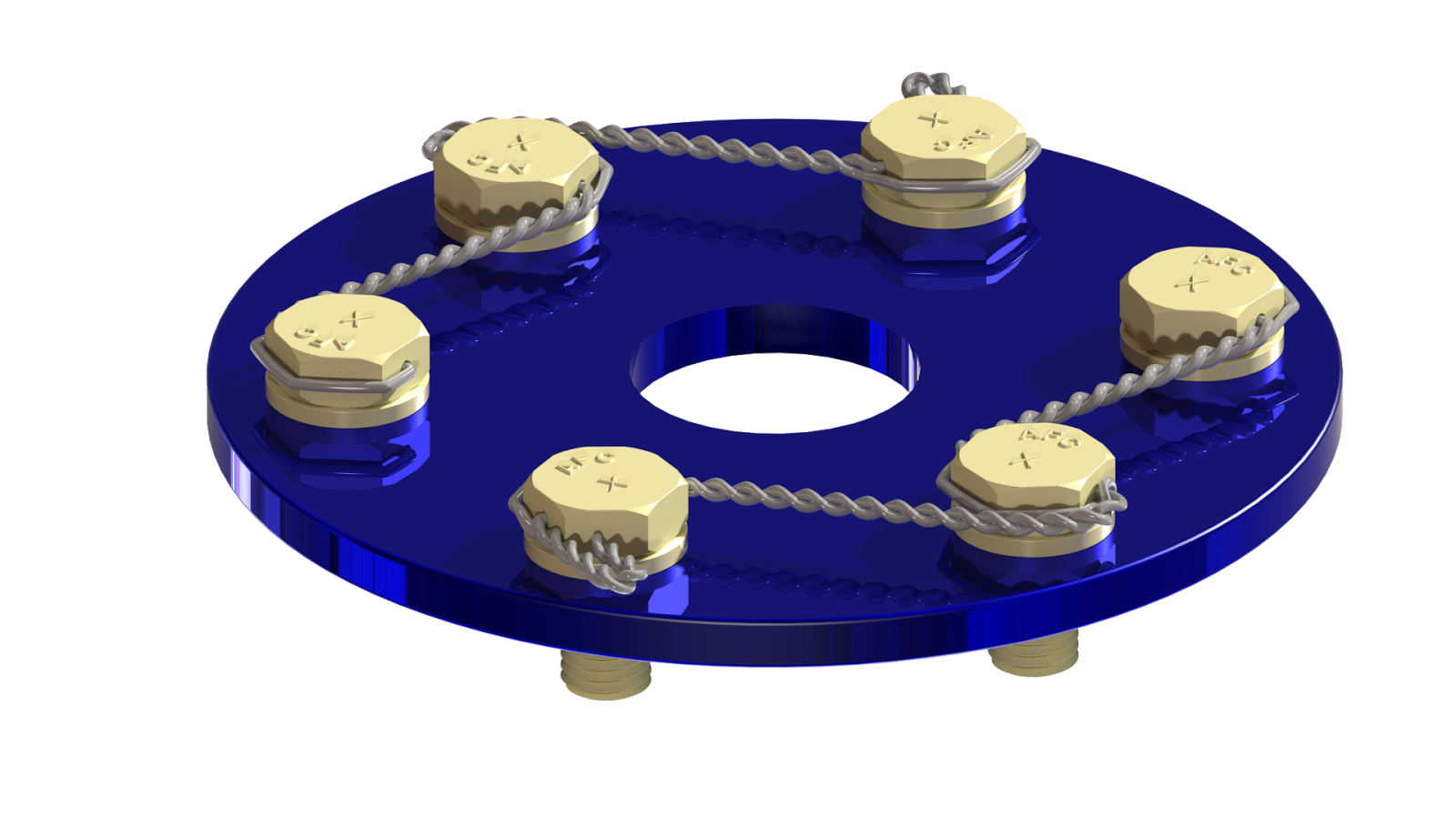

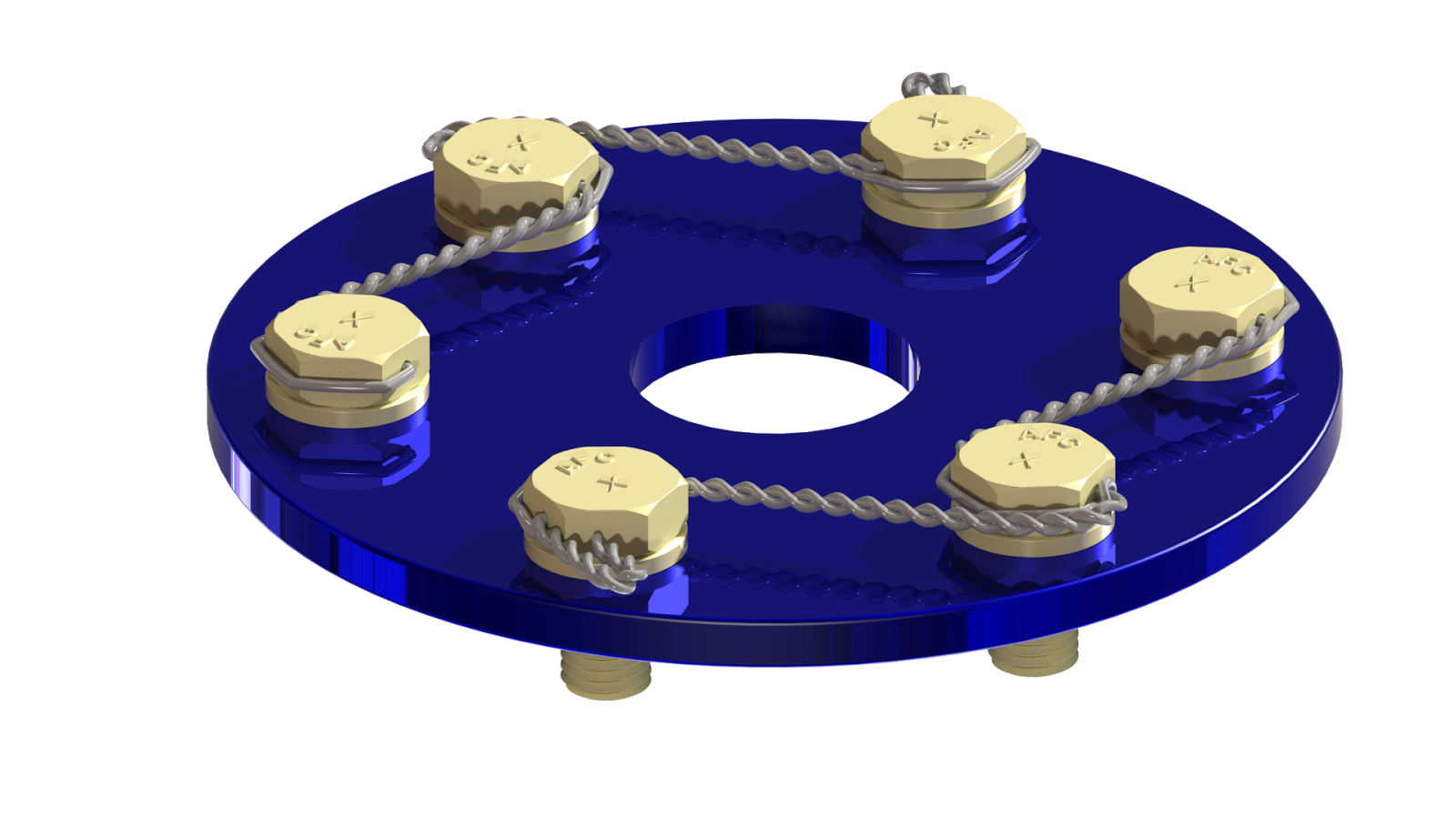

You can always safety wire them . . .

Yep safety wire.

I did it when I was flying. Never had a prop or oil filter come off during flight.

However I have never done it on an automobile and still never had a filter come off thank goodness.

Forget the thread locker. Just tighten in manner that does not cause issues and then torque to proper value

I did it when I was flying. Never had a prop or oil filter come off during flight.

However I have never done it on an automobile and still never had a filter come off thank goodness.

Forget the thread locker. Just tighten in manner that does not cause issues and then torque to proper value

For any loctite to work you would have to have absolutely NO oil on both the threads in the oil pan drain hole, and the threads on the drain bolt, and there is no way that is going to happen.

Originally Posted By: JimPghPA

For any loctite to work you would have to have absolutely NO oil on both the threads in the oil pan drain hole, and the threads on the drain bolt, and there is no way that is going to happen.

He's not talking about the drain plug; he's talking about the bolts that bolt the oil pan to the engine.

For any loctite to work you would have to have absolutely NO oil on both the threads in the oil pan drain hole, and the threads on the drain bolt, and there is no way that is going to happen.

He's not talking about the drain plug; he's talking about the bolts that bolt the oil pan to the engine.

I think you guys are overthinking this. Maybe it's because I've been doing mechanical stuff for 35+ years, but I have a feel for the tightness on bolts like this. I've never used a torque wrench on pan bolts and never had an issue.

Originally Posted By: Silverado12

I think you guys are overthinking this. Maybe it's because I've been doing mechanical stuff for 35+ years, but I have a feel for the tightness on bolts like this. I've never used a torque wrench on pan bolts and never had an issue.

Old argument, but it won't die.

I have a torque wrench but seldom use it, partly because I don't usually feel its necessary, but mostly because the specs, when available, usually assume dry, un-lubricated threads.

There is no way I'm using dry, un-lubricated threads, so little point in me using a torque wrench.

Lately I've been using polythene on threads (e.g. wheel studs) and intend doing this more in the future, though I dunno if I'd bother with sump bolts, which (on my cars anyway) are generally oily enough.

My impression is that the polythene has a bit of a thread-locking effect, nylock stylee.

It might be especially useful on motorcycles, which on the one hand get a lot of vibration and on the other suffer horribly from stuck fastners.

I think you guys are overthinking this. Maybe it's because I've been doing mechanical stuff for 35+ years, but I have a feel for the tightness on bolts like this. I've never used a torque wrench on pan bolts and never had an issue.

Old argument, but it won't die.

I have a torque wrench but seldom use it, partly because I don't usually feel its necessary, but mostly because the specs, when available, usually assume dry, un-lubricated threads.

There is no way I'm using dry, un-lubricated threads, so little point in me using a torque wrench.

Lately I've been using polythene on threads (e.g. wheel studs) and intend doing this more in the future, though I dunno if I'd bother with sump bolts, which (on my cars anyway) are generally oily enough.

My impression is that the polythene has a bit of a thread-locking effect, nylock stylee.

It might be especially useful on motorcycles, which on the one hand get a lot of vibration and on the other suffer horribly from stuck fastners.

Probably nothing wrong with using the weakest thread locker (Purple, I think).

Not needed - if it makes you sleep better at night you can use blue Loctite 243(or the Permatex equivalent, it's the oil-tolerant stuff).

Torque matters more, it think it's a low value(3-5ft-lb, a 5Nm bike torque key wouldn't hurt). Check the FSM.

Torque matters more, it think it's a low value(3-5ft-lb, a 5Nm bike torque key wouldn't hurt). Check the FSM.

- Status

- Not open for further replies.

Similar threads

- Replies

- 9

- Views

- 986

- Replies

- 30

- Views

- 3K

- Replies

- 33

- Views

- 2K