My question:

I was looking at your LF613 filter as a replacement for my PF48 filter on my 4.8 Silverado. I had a couple of questions:

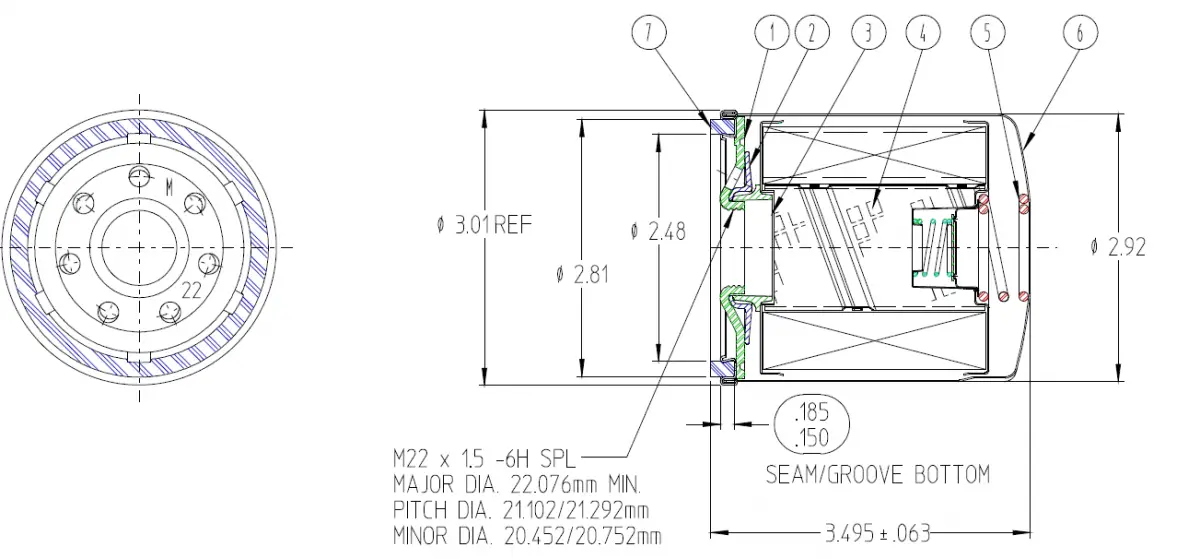

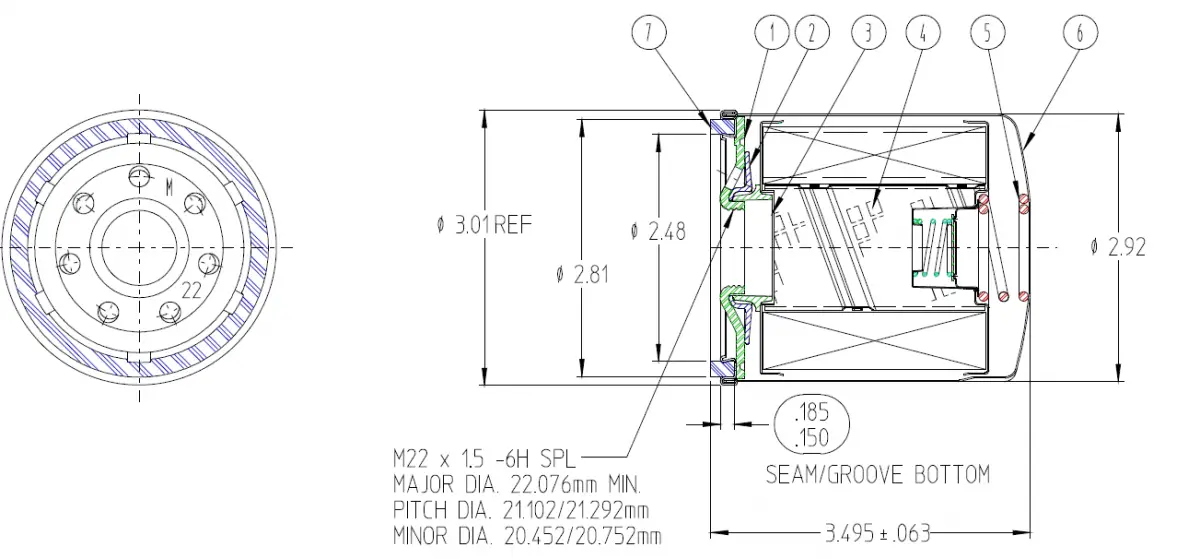

I just want to confirm that the location of the bypass valve on the LF613 is at the filter inlet, not at the top of the element as on the ACDelco PF48. The Delco's arrangement seems inferior to me.

Secondly, and more importantly, the bypass valve on the Delco operates at approximately 9-12 psi, or something in that neighborhood (from what I understand). The specs for the LF613 indicate that the bypass becomes operational at 20psi. Is this large desparity a problem? Will my engine be starved of oil at high rpms because the bypass on the LF613 requires a higher pressure to operate?

Thanks for your time.

Answer Given:

Thank you for using Hastings filters. The by-pass valve in the LF613 is at the top of the element. This valve is set to open when the differential pressure across the element reaches 20 psid. Engineering evaluated the AC Delco filter in 2006 and determined that the by-pass valve in that filter opened at 18.84 psid. Therefore, the by-pass valve in the LF613 opens at nearly the same level of restriction as the AC Delco filter.

I was looking at your LF613 filter as a replacement for my PF48 filter on my 4.8 Silverado. I had a couple of questions:

I just want to confirm that the location of the bypass valve on the LF613 is at the filter inlet, not at the top of the element as on the ACDelco PF48. The Delco's arrangement seems inferior to me.

Secondly, and more importantly, the bypass valve on the Delco operates at approximately 9-12 psi, or something in that neighborhood (from what I understand). The specs for the LF613 indicate that the bypass becomes operational at 20psi. Is this large desparity a problem? Will my engine be starved of oil at high rpms because the bypass on the LF613 requires a higher pressure to operate?

Thanks for your time.

Answer Given:

Thank you for using Hastings filters. The by-pass valve in the LF613 is at the top of the element. This valve is set to open when the differential pressure across the element reaches 20 psid. Engineering evaluated the AC Delco filter in 2006 and determined that the by-pass valve in that filter opened at 18.84 psid. Therefore, the by-pass valve in the LF613 opens at nearly the same level of restriction as the AC Delco filter.