I am a student at CSU Fresno and my Graduate Report is on the Evaluation and Testing of Automotive Oil Filters. In conducting the research, it became obvious that oil filters with either a synthetic or synthetic/cellulose blend almost always seem to have a smaller total surface area for their filtering media.

It seems logical that a synthetic filtering media could have a smaller filtering media and still capture smaller micron particles than a cellulose media, but it also seems logical that the total holding capacity of the synthetic media would be less due to the smaller total surface area.

The synthetic media oil filters are also generally recommended for longer drain intervals which is worrisome due to the smaller synthetic filtering medias total surface area, and the fact that the synthetic fibers will capture and hold smaller particles. Thus it is likely that the filter will become clogged faster with debris which would result in the oil bypass valve opening and defeating the purpose of the filtering element functioning as intended.

For example the Amsoil EAO 20 oil filter having the smallest filtering surface area of the test sample seems contradictory to Amsoil’s claim that their filter can last up to 25,000 miles. In fact their total surface area is 2.84 times smaller than the OEM Hyundai oil filter which it is a replacement for. Amsoil technical support also claims that all holding capacities of their oil filters are Proprietary information so I can not compare the holding capacity in grams from a full synthetic Amsoil Filtering Media to a standard cellulose filtering media.

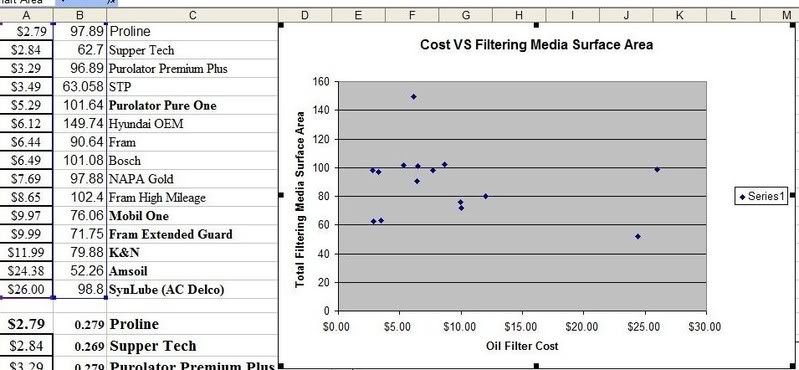

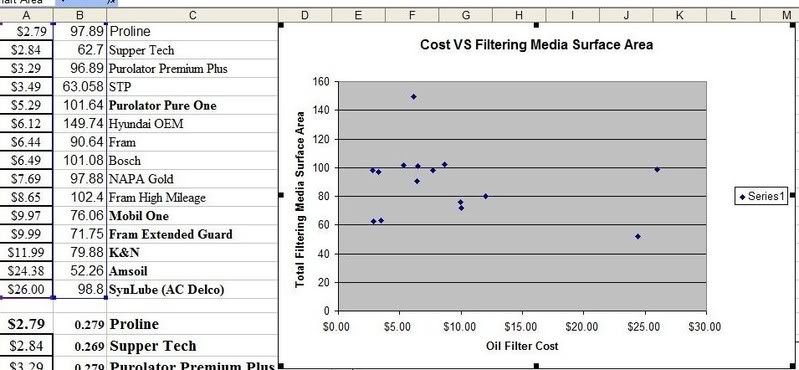

Hear is a picture of a graph showing the cost to total surface area of the filtering element:

In conclusion, my question is how can a smaller total surface area of synthetic filtering media have the ability to hold more total contaminant assuming the oil bypass valve on a synthetic and cellulose oil filter open at the same PSI?

If there is a study I missed in my research, please provide a link or article title.

Thank you for your help.

It seems logical that a synthetic filtering media could have a smaller filtering media and still capture smaller micron particles than a cellulose media, but it also seems logical that the total holding capacity of the synthetic media would be less due to the smaller total surface area.

The synthetic media oil filters are also generally recommended for longer drain intervals which is worrisome due to the smaller synthetic filtering medias total surface area, and the fact that the synthetic fibers will capture and hold smaller particles. Thus it is likely that the filter will become clogged faster with debris which would result in the oil bypass valve opening and defeating the purpose of the filtering element functioning as intended.

For example the Amsoil EAO 20 oil filter having the smallest filtering surface area of the test sample seems contradictory to Amsoil’s claim that their filter can last up to 25,000 miles. In fact their total surface area is 2.84 times smaller than the OEM Hyundai oil filter which it is a replacement for. Amsoil technical support also claims that all holding capacities of their oil filters are Proprietary information so I can not compare the holding capacity in grams from a full synthetic Amsoil Filtering Media to a standard cellulose filtering media.

Hear is a picture of a graph showing the cost to total surface area of the filtering element:

In conclusion, my question is how can a smaller total surface area of synthetic filtering media have the ability to hold more total contaminant assuming the oil bypass valve on a synthetic and cellulose oil filter open at the same PSI?

If there is a study I missed in my research, please provide a link or article title.

Thank you for your help.

Last edited: