Originally Posted By: nicrfe1370

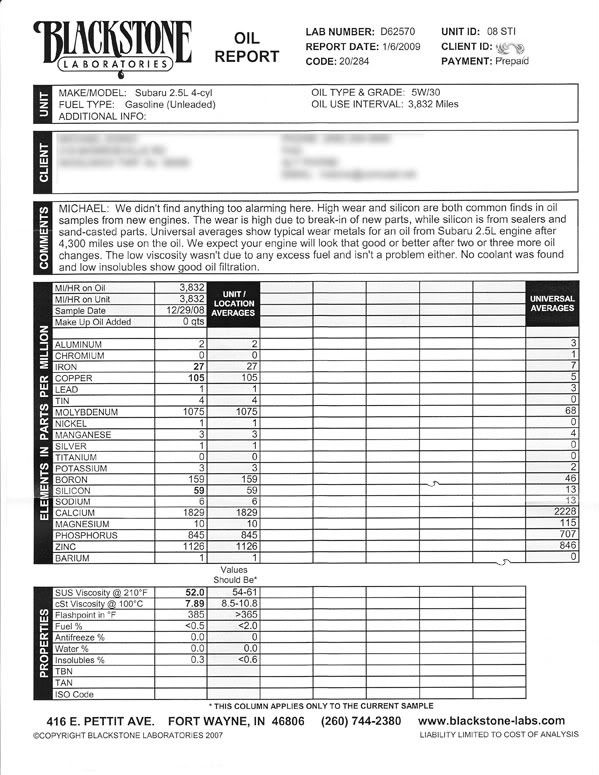

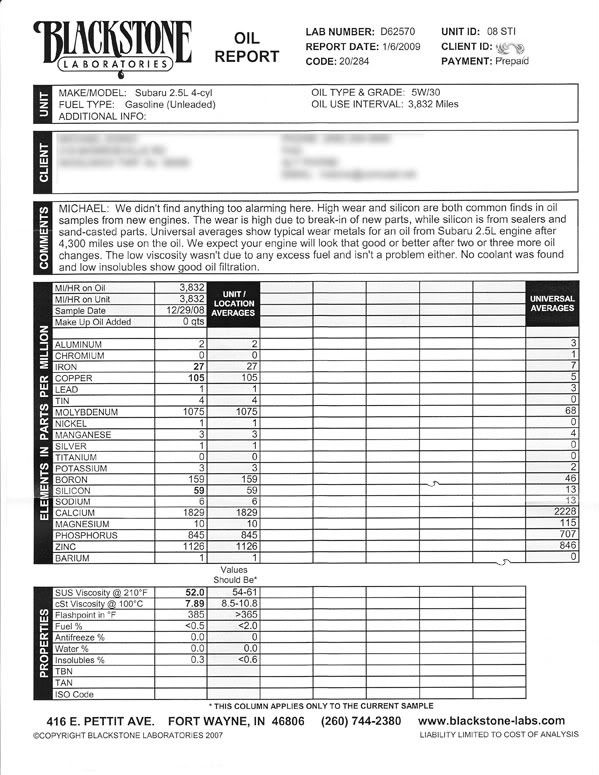

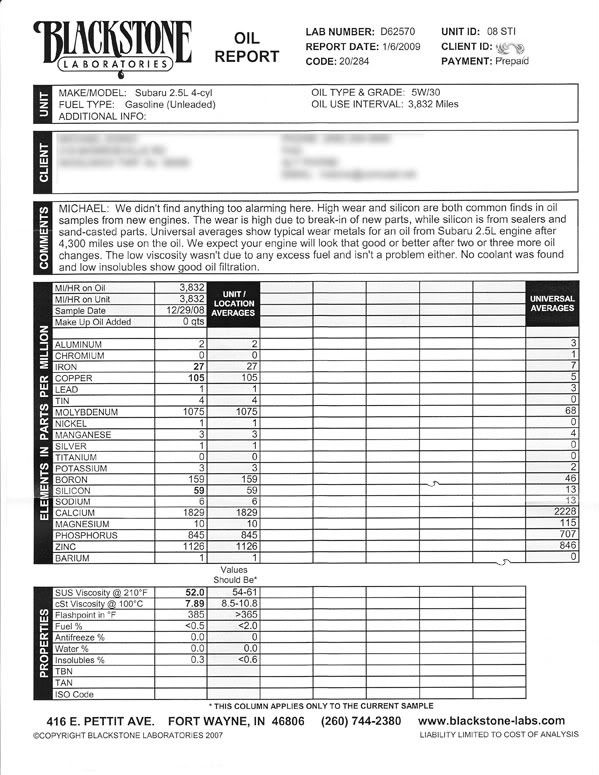

Merlot, that is WAY more copper than I am comfortable with in a Subaru. They never show this much, not even during break in. Tell me more about this "stop sale" and copper chips you mentioned, I have no idea what that's about. Unless you are 100% comfortable with the findings here, I would highly recommend you talk to Terry and get his very valuable professional opinion.

I don't know who Terry is. Anyway, here's a the specific procedure Subaru instructed dealers to do on vehicles in a certain VIN range:

Quote:

Turbo Engine Stop Sale checking Procedure

On April 7, 2008 we informed you of a stop sale order on 2008 Impreza, STi and Legacy vehicles and 2009 Forester vehicles equipped with 2.5L Turbo Engines and produced with the beginning chassis number/production dates and later as shown below:

Model Body Type Chassis Number Production Date

Forester Wagon 701045 or later 2008/01/08 or later

Legacy 2.5GT-LTD 222825 or later 2008/02/04 or later

2.5GT-B 222958 or later

OBK 2.5XT-LTD 353835 or later 2008/02/01 or later

Impreza Sedan 523363 or later 2008/01/08 or later

Wagon 825183 or later

We took this action as a “Customer First” preventive action as we had confirmed, in other markets, that there was a small possibility of an “Engine Knocking Noise” caused by a contamination in the area of the connecting rod big end journal at very low mileage/time in service.

The action was successful in preventing the potential of failures for our customers.

Subaru has defined a screening process that you must perform to all of the affected vehicles in your inventory before delivery to a customer or putting in demonstrator service.

The screening process consists of several steps to inspect the condition of the engine oil to determine if the engine is not affected by the contamination, is already damaged, or has a potential for damage.

Both a flow chart and detailed instruction sheet of the process are included in this document. Each step must be followed exactly, no short cuts.

As soon as the engine is determined to be in proper working condition, it can be sold or put into demo service.

To perform the screening, you will need the following materials for each vehicle:

• New magnetic Oil Pan Drain Plug (1) (32103KA000 - only this P/N is acceptable)

• New Oil Drain Plug Gasket (1) (11126AA000)

• New Oil Filter (1) (15208AA100)

• Engine Oil 5w30

• Filter paper (such as a standard automotive funnel type paint filter)

• Clear plastic “wash bottle” 16oz (500ml), with angled flexible snorkel:

Please order a plastic wash bottle, 16 ounce (500ml / 500cc), translucent color for observing the color of the oil. The cap and pick-up tube colors are not important for this test. We suggest using the following suppliers and supply houses to locate the plastic wash bottle or equivalent:

• W.W. Grainger Supply, Inc. -

http://www.grainger.com/

• Fisher Scientic, Inc. -

http://www.fishersci.com

• Most Medical Supply Locations

• Most Beauty Supply Locations

Note: It is important that the opening at the tip of the flexible snorkel be at least 3mm inside diameter in order to properly allow any contamination that may be present in the bottom of the oil pan to pass through into the bottle. It may be necessary to trim the flexible snorkel to obtain the 3mm opening. See picture in flowchart on page 4.

Detailed Instructions

You will need to refer to the flow chart provided to follow this written procedure and refer to the photos and graphics for examples.

Always follow all environmental and hazardous waste handling precautions to prevent any contamination or safety issues.

Engine Screening Procedure One

1) Drain the engine oil through the drain plug.

2) Using the wash bottle, insert the tip of the snorkel through the drain hole, ensuring that the tip is between the bottom of the pick-up screen and the oil pan. Note: The wash bottle can be re-used, but it must be thoroughly cleaned with aqueous parts cleaner and dried. All residual oil, particles and cleaner must be removed to ensure that no false judgments are made.

3) Siphon the remaining oil and residue from the oil pan as shown in the drawing (approximately 100cc).

4) Observe the color and clarity of the oil in the wash bottle, and compare it to the examples in the photo found on the flowchart on page 4.

NOTE: If the wash bottle is not clear, pour the oil and residue into a clear glass container to make a good judgment.

5) If the oil is clear, the engine is okay.

A) Replace the oil filter, install a new magnetic Oil Plug and new Oil Plug Gasket, and refill with fresh engine oil.

Engine Screening Procedure Two

6) If the oil clarity or color matches the “Needs Check” samples, strain the oil through the filter paper and capture the material residue.

A)If there are copper particles larger that 1 mm in the material residue, the engine is damaged. Immediately submit an E-QMR and wait for further instructions.

NOTE: It may be necessary to clean the particles to determine if they are copper. Copper is reddish in color. There may be very small particles of other materials that are typical of a new engine, such as silicon, aluminum and ferrous (steel or magnetic) content, that do not indicate any failure.

B)If there are no copper particles, or they are smaller than 1 mm, proceed to step 7.

7) Install a new magnetic Oil Drain Plug, reusing the original gasket and engine oil filter, and refill the engine with fresh oil.

8)Start the engine and let it idle for five (5) minutes to flush any residue from the oil passages.

A)Stop the engine, drain the oil, remove and replace the oil filter, clean and reinstall the magnetic drain pug, using the new gasket.

B)Refill with fresh oil.

9)Re-start the engine and let it idle for 5 minutes.

Note: Be sure to allow the Air Pump operation to complete its cycle. It will be difficult to distinguish any engine noise while the pump is operating.

A)Quickly rev and release the engine to 6,000 rpm at least 10 (ten) times. Caution: Do not exceed 6000 rpm or hold above the red line.

Note: Be sure to follow the “Reving Procedure” found on the flow chart located on page 4.

B)Let the engine idle for a few seconds; then increase and decrease the rpm slowly to 2500 rpm, while listening for abnormal lower end engine noise.

10) If lower end engine noise is evident, immediately stop the engine and submit an E-QMR and wait for further instructions.

11) If no noise, the engine is okay, and the vehicle can be released for retail sale.