First, here are some previous test results I obtained. It shows the tight control I keep over the testing.

http://theoildrop.server101.com/forums/s...rt=all&vc=1

Now I'll discuss the RLI Oil Experiment. I heated it for 12 hours at approximately 340F in an anodized aluminum cup; same for M1 0W-40 as a reference. I measured volatility at 1, 2, and 12 hours. The M1 0W-40 was less volatile. My notes are at home right now...from memory, the M1 lost 0.07 grams in one hour while RLI lost 0.1 grams. Not a big deal and that M1 is less volatile that almost every other oil I've tested. All oil's volatility drops as time goes on in these tests. Between 2 and 12 hours, RLI oil volatility dropped much more than the M1 oil's volatility dropped. This might indicate oxidative thickening of the RLI oil. I'd have to measure volatility at each hour and then calculate the rate of change of the volatility to get a better idea of this.

A simple crude viscosity test (at room temp) done by tilting the two cups of oils and comparing how fast the oil flows showed that the RLI oil started the test more viscous than M1, and at 12 hours, the difference between the viscosity of the two oils increased. I can't attribute it purely to oxidative thickening without a doubt because perhaps the VIIs in M1 "cracked", lowering the viscosity. More testing could answer this.

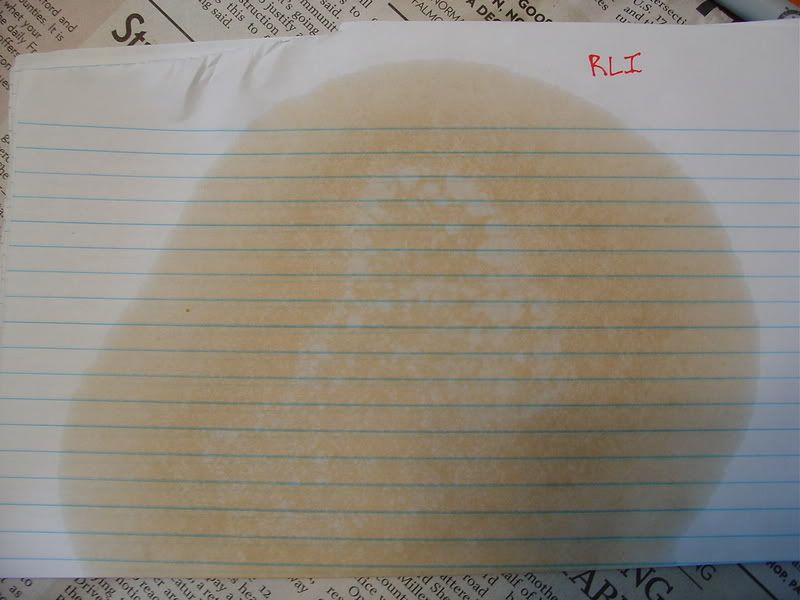

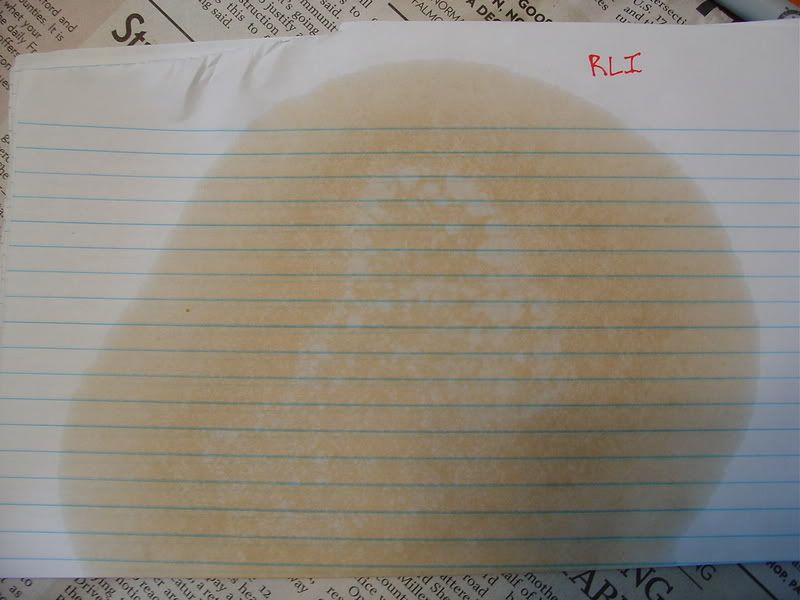

The real reason for testing is for oxidation and deposit formation. Neither oil left any deposits in the cups. The odd thing is that the RLI oil seemed to separate out quite a few clear "globules". They could be seen floating in the oil while it was in the cup. I poured the contents onto a folded piece of paper. The clear globules did not absorb into the paper nearly as fast as the rest of the oil. Some still were not absorbed into the paper 1 week later. That could be explained by the globules being oxidized/thickened HOBS oil that were not in solution with the rest of the oil. A picture of this is shown below.

Even before I heated the oil while it was in the cup, when I shook the oil, it looked like it was not a complete solution. I saw some color gradients...clear vs. dark brown. But the clear regions were not semi-solid globules like showed up at the end of this test. I think the former turned into the latter during the testing.

A test length of twelve hours in these cups without any catalysts in the oil is not nearly as severe as some other tests I've done.

http://theoildrop.server101.com/forums/s...rt=all&vc=1

Now I'll discuss the RLI Oil Experiment. I heated it for 12 hours at approximately 340F in an anodized aluminum cup; same for M1 0W-40 as a reference. I measured volatility at 1, 2, and 12 hours. The M1 0W-40 was less volatile. My notes are at home right now...from memory, the M1 lost 0.07 grams in one hour while RLI lost 0.1 grams. Not a big deal and that M1 is less volatile that almost every other oil I've tested. All oil's volatility drops as time goes on in these tests. Between 2 and 12 hours, RLI oil volatility dropped much more than the M1 oil's volatility dropped. This might indicate oxidative thickening of the RLI oil. I'd have to measure volatility at each hour and then calculate the rate of change of the volatility to get a better idea of this.

A simple crude viscosity test (at room temp) done by tilting the two cups of oils and comparing how fast the oil flows showed that the RLI oil started the test more viscous than M1, and at 12 hours, the difference between the viscosity of the two oils increased. I can't attribute it purely to oxidative thickening without a doubt because perhaps the VIIs in M1 "cracked", lowering the viscosity. More testing could answer this.

The real reason for testing is for oxidation and deposit formation. Neither oil left any deposits in the cups. The odd thing is that the RLI oil seemed to separate out quite a few clear "globules". They could be seen floating in the oil while it was in the cup. I poured the contents onto a folded piece of paper. The clear globules did not absorb into the paper nearly as fast as the rest of the oil. Some still were not absorbed into the paper 1 week later. That could be explained by the globules being oxidized/thickened HOBS oil that were not in solution with the rest of the oil. A picture of this is shown below.

Even before I heated the oil while it was in the cup, when I shook the oil, it looked like it was not a complete solution. I saw some color gradients...clear vs. dark brown. But the clear regions were not semi-solid globules like showed up at the end of this test. I think the former turned into the latter during the testing.

A test length of twelve hours in these cups without any catalysts in the oil is not nearly as severe as some other tests I've done.