If the second filter, the bypass filter, in an Amsoil dual remote takes the same high pressure oil as the full flow filter filter and has a higher pressure drop than the full filter along with a lower flow rate, how does it return the oil back to the return line when the return pressure of the bypass is lower than the return pressure from the full flow filter? I know there is a little spring and a valve body in there but how does all this work?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Still not sure how an Amsoil dual bypass works.

- Thread starter LarryL

- Start date

- Status

- Not open for further replies.

my guess:

one way valve?

one way valve?

Think of it as an electrical circuit. You can have a 1 ohm resistor and a 100 ohm resistor in parallel and electricity will still flow through the 100 ohm resistor, just not as much as through the 1 ohm resistor.

Both filters feed off the same pressure line and return their clean oil to the same return line, so they are in parallel. The bypass will have more resistance but oil will still flow through it. The ball and spring decreases inlet pressure on the full-flow and increases inlet pressure on the bypass to help force more oil through it.

Both filters feed off the same pressure line and return their clean oil to the same return line, so they are in parallel. The bypass will have more resistance but oil will still flow through it. The ball and spring decreases inlet pressure on the full-flow and increases inlet pressure on the bypass to help force more oil through it.

I've got it figured out. You are right as far as you go, but it's the pressure drop across the spring valve plus the pressure drop across the full flow filter that lowers the downstream pressure enough to allow the bypass filter to actually flow oil and return it. As the full filter does its work it gradually builds a little more delta and the full flow filter sees a little more flow. If the spring breaks the full flow oil will be at its max and the bypass will see less flow.

Larry, the resistance of the spring valve causes the pressure control valve in the oil pump assembly to dump more oil back into the sump. This results in less oil to the engine. Apparently, this doesn't matter, but I wouldn't do it. I'd rather have the single bypass filter, not the dual assembly.

Ken

Ken

The Dual Remote allows all of the oil to go to the engine, rather than having some of it bled off. If the oil pressure doesn't get to the engine's pressure relief valve setting, none of the oil will get dumped back into the sump.quote:

Originally posted by Ken2:

Larry, the resistance of the spring valve causes the pressure control valve in the oil pump assembly to dump more oil back into the sump. This results in less oil to the engine. Apparently, this doesn't matter, but I wouldn't do it. I'd rather have the single bypass filter, not the dual assembly.

Ken

That's why I have an oil pressure gauge. It is also why I've switched to 0W-30 oil, although I didn't have a problem when I used 10W30. My pressure gauge tells me that I'm not getting to max pressure, at least with my vehicle. Some vehicles may have relatively low pressure relief settings, and it may go into bypass. If you really like using the dual remote setup, you can always put a washer behind the bypass spring, increasing the bypass pressure.

Sorry, I just completely do not understand this reasoning.quote:

Originally posted by Ken2:

Larry, the resistance of the spring valve causes the pressure control valve in the oil pump assembly to dump more oil back into the sump. This results in less oil to the engine. Apparently, this doesn't matter, but I wouldn't do it. I'd rather have the single bypass filter, not the dual assembly.

Ken

Isn't the bypass filter in parallel with the fullflow filter? Isn't the restrictor valve to the bypass filter AFTER the fullflow filter nd before the bypass filter- thus, not affecting the pressure control valve in the oil pump at all?

This is why I put a Frantz bypass on my 3 chevies, very simple, chevy oil pumps will usually out pump the demand and lastly and most importantly, I understand how it works! LOL

I put my mad artistic skills to good use and made a diagram that should explain everything.quote:

Originally posted by burntkat:

Isn't the bypass filter in parallel with the fullflow filter? Isn't the restrictor valve to the bypass filter AFTER the fullflow filter nd before the bypass filter- thus, not affecting the pressure control valve in the oil pump at all?

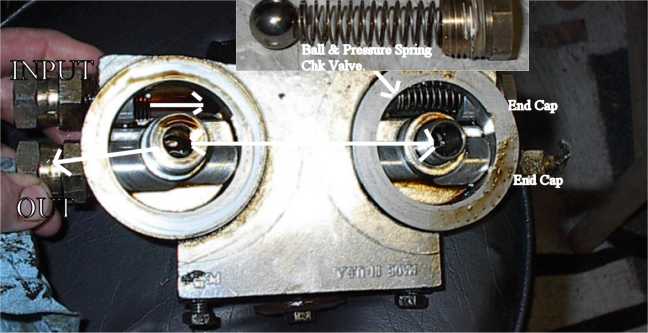

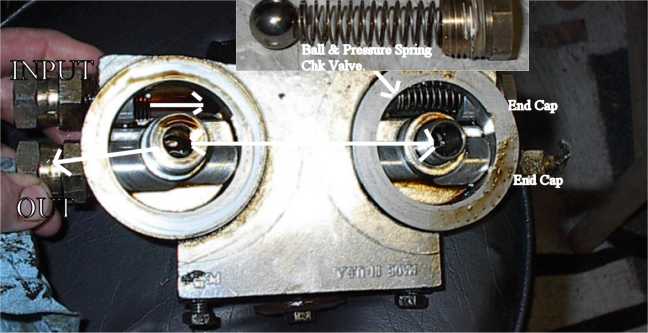

Imagine looking down at the top of the filter mount block. The 2 long rectangles are the 2 tubes bored into the block to flow oil in and out. As you can see, the filters are in parallel and the restictor is located after the bypass filter and before the full-flow.

Just to add to the above, the Amsoil dual remote bypass mount is definitely more restrictive to oil flow than a regular full-flow screwed to the block in the OEM location. If you look at the fluid flow in the pic I posted, you see that the oil has to pass through the bypass element and the restrictor valve, both are restrictive by design. So the oil pump is going to have to work a little harder to pump the oil through. But oil pumps are positive displacement pumps so you will not lose any flow volume. The pressure upstream of the mount may be slightly higher though. So I could see how it could affect the operation of the pressure relief valve or bypass valve in the engine block. When the oil is cold those valves may stay open a little longer. But once the oil is warmed up a bit, a few extra PSI won't open the valves.

In my opinion though, this is all just trivial hair-splitting. Plenty of oil will still be flowing eveywhere it needs to go.

In my opinion though, this is all just trivial hair-splitting. Plenty of oil will still be flowing eveywhere it needs to go.

Larry,

Oil pressure is not the best way to measure oil, but it's expensive to measure oil flow, so a pressure gage is an inexpensive way of determining oil flow. Since oil pumps are positive displacement pumps, the oil flow remains realitively the same. Changing the opening will directly affect the oil pressure and the speed it moves at.

A smaller opening will result in an increase in puressure in the pipe before the opening. A larger opening will result in a decrese in pressure in the pipe after the opening.

The math is complex, but the concept is simple.

The restrictor valve causes a smaller opening for the oil to travel though. If the rate of flow remains the same, the pressure in front of the valve will increase, and the oil will move faster past the restrictor.

That will increase the pressure on the inflow side of the bypass filter, which means there is a greater pressure difference between the in and out side of the by-pass filter. That will result in more oil flowing through the by-pass.

As for the full flow, both the input and output are after the restrictor, so the pressure difference between the two sides is smaller.

There is always less pressure on the out side than the in side. The pressure difference is directly related to the rate of flow. In the case of a positive displacement pump the flow is a constant, and the pressure is changed to achieve that flow rate.

Oil pressure is not the best way to measure oil, but it's expensive to measure oil flow, so a pressure gage is an inexpensive way of determining oil flow. Since oil pumps are positive displacement pumps, the oil flow remains realitively the same. Changing the opening will directly affect the oil pressure and the speed it moves at.

A smaller opening will result in an increase in puressure in the pipe before the opening. A larger opening will result in a decrese in pressure in the pipe after the opening.

The math is complex, but the concept is simple.

The restrictor valve causes a smaller opening for the oil to travel though. If the rate of flow remains the same, the pressure in front of the valve will increase, and the oil will move faster past the restrictor.

That will increase the pressure on the inflow side of the bypass filter, which means there is a greater pressure difference between the in and out side of the by-pass filter. That will result in more oil flowing through the by-pass.

As for the full flow, both the input and output are after the restrictor, so the pressure difference between the two sides is smaller.

There is always less pressure on the out side than the in side. The pressure difference is directly related to the rate of flow. In the case of a positive displacement pump the flow is a constant, and the pressure is changed to achieve that flow rate.

Sorry, this doesn't make sense to me unless the FF and BP were reversed.quote:

Originally posted by olympic:

I put my mad artistic skills to good use and made a diagram that should explain everything.quote:

Originally posted by burntkat:

Isn't the bypass filter in parallel with the fullflow filter? Isn't the restrictor valve to the bypass filter AFTER the fullflow filter nd before the bypass filter- thus, not affecting the pressure control valve in the oil pump at all?

Imagine looking down at the top of the filter mount block. The 2 long rectangles are the 2 tubes bored into the block to flow oil in and out. As you can see, the filters are in parallel and the restictor is located after the bypass filter and before the full-flow.

To slow down the oil flow through the BP, it requires a restriction on it's input, from all I have seen. Your drawing is putting the restriction on the input of the FF and leaving the BP to get full flow of the oil pump, the way I understand it.

What don't I understand here?

right. this is the way I understand it.quote:

Originally posted by greencrew:

The restrictor valve causes a smaller opening for the oil to travel though. If the rate of flow remains the same, the pressure in front of the valve will increase, and the oil will move faster past the restrictor.

That will increase the pressure on the inflow side of the bypass filter, which means there is a greater pressure difference between the in and out side of the by-pass filter. That will result in more oil flowing through the by-pass.

but I thought the idea was to run the oil through the bypass filter as SLOWLY and at as little pressure as possible, in order to get a really good scrub of the oil?

Sounds like Amsoil got it backwards?

Pretty sure the motorguard has a restrictor in it as well. Granted it's not directly in parallel with the FF filter- but wouldn't it be a better design to reverse the location of the BP and FF filters in the drawing above?

I think I have a grasp on the principles at play here-- but it seems as though Amsoil is doing it bass-ackwards..

You're missing the forest for the trees my friend. Putting aside greencrew's explanation of Bernoulli's Principle for a moment it's often helpful to look at extremes to understand what's happening in the middle.

In the diagram above imagine the restrictor removed and the outlet from the filter mount (on the left) open with no back pressure. In such a case oil will take the path of least resistance and most, if not all, will go thru the full flow filter. It does so because the bypass filter offers more resistance to flow than the full flow filter.

Now place a solid plug where the restrictor is. Where does all the oil go? Where does it *have* to go? Now vary the size of the orifice in the restrictor plug. You need some restriction to develop a pressure drop across the bypass filter or the oil wouldn't go thru it. It's restrictive on it's on so you need to develop enough pressure to over come it.

Keep in mind that everything in nature flows from high to low and always takes the path of least resistance. Pressure, temperature, etc. Pumps don't work by pushing, they work by creating a lower pressure at the inlet than the outlet. The same way vacuum doesn't "suck". By creating a delta P it's power of the ambient atmospheric pressure that does the work. Get it?

I'd add that this isn't the only way to skin this cat but that's what's happening in this schematic.

[ October 19, 2005, 12:11 AM: Message edited by: chenobylite ]

In the diagram above imagine the restrictor removed and the outlet from the filter mount (on the left) open with no back pressure. In such a case oil will take the path of least resistance and most, if not all, will go thru the full flow filter. It does so because the bypass filter offers more resistance to flow than the full flow filter.

Now place a solid plug where the restrictor is. Where does all the oil go? Where does it *have* to go? Now vary the size of the orifice in the restrictor plug. You need some restriction to develop a pressure drop across the bypass filter or the oil wouldn't go thru it. It's restrictive on it's on so you need to develop enough pressure to over come it.

Keep in mind that everything in nature flows from high to low and always takes the path of least resistance. Pressure, temperature, etc. Pumps don't work by pushing, they work by creating a lower pressure at the inlet than the outlet. The same way vacuum doesn't "suck". By creating a delta P it's power of the ambient atmospheric pressure that does the work. Get it?

I'd add that this isn't the only way to skin this cat but that's what's happening in this schematic.

[ October 19, 2005, 12:11 AM: Message edited by: chenobylite ]

Chenobylite is correct in his description of how the BMK-13 works. Here is a picture of an earlier version of this housing:

If the restrictor valve was removed, very little oil would flow through the bypass filter. To get the total flow to around 10%, the spring loaded valve raises the pressure going to the bypass filter relative to the full-flow filter.

If the restrictor valve was removed, very little oil would flow through the bypass filter. To get the total flow to around 10%, the spring loaded valve raises the pressure going to the bypass filter relative to the full-flow filter.

Good stuff. I was wondering what the internals on those things actually looked like. Yeah, lets just say the oil "piles up" in front of the restriction and has to go somewhere. That somewhere is thru the BP filter. The thing is the Purolator spin on BP filters I just bought have their own restrictors built right in so I'll have to play with adding a restrictor to the full flow mount I'm going to use. I may not even need a second orifice.

Thanks guys- I'm familiar with Entropy, I just need to think a bit.

Those filters you just bought that have the restrictor in them are exactly the kind of thing I'm thinking about. Still not sure why that works in that instance yet the Amsoil job does it the exact opposite way. I just need some time to get my head around it.

Those filters you just bought that have the restrictor in them are exactly the kind of thing I'm thinking about. Still not sure why that works in that instance yet the Amsoil job does it the exact opposite way. I just need some time to get my head around it.

It's true, the design of the BMK13 has the bypass filter unrestricited and tries to push as much oil through it as possible. But Amsoil claims it still only flows about 1 quart per minute.

A restrictor is needed in a stand-alone bypass because it has full engine oil pressure on the inlet and zero oil pressure on the outlet. So there could be a 40-60psi+ pressure differential. On the BMK 13, there is pressure on both sides so the differential is much less, meaning less flow through the bypass.

A restrictor is needed in a stand-alone bypass because it has full engine oil pressure on the inlet and zero oil pressure on the outlet. So there could be a 40-60psi+ pressure differential. On the BMK 13, there is pressure on both sides so the differential is much less, meaning less flow through the bypass.

- Status

- Not open for further replies.

Similar threads

- Replies

- 10

- Views

- 561

- Replies

- 35

- Views

- 2K