I now have some clues as to what might be causing at least part of the problem.

I tried using a vacuum gauge that I bought in Japan, to tune the idle. So far I can't see its much better than tuning by ear, but it did "accidentally" give me some info.

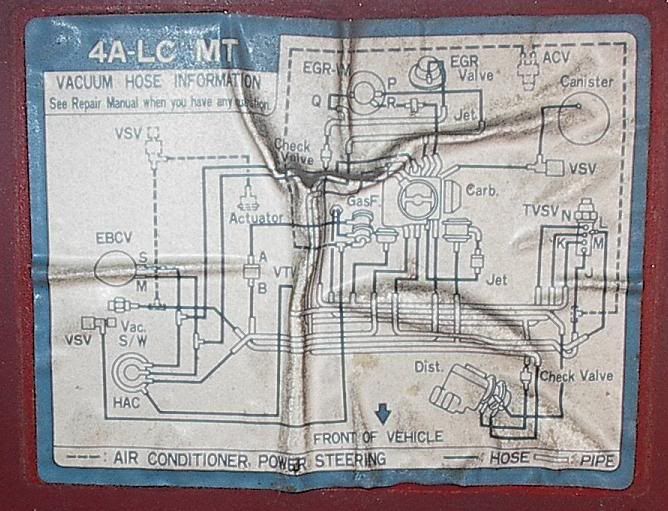

I wasn't sure where to plug it in, and tried one of the vacuum advance hoses to the distributor.

I noticed that the idle was steadier while doing this. Possible explanations include:-

(a) There is a vacuum leak via the vacuum advance circuit, perhaps due to a hole in its diaphragm. This will disturb the idle.

(b) As a result of (a), the vacuum advance doesn't work, so the spark happens late. This will disturb the idle too.

http://chevellestuff.net/tech/articles/vacuum/port_or_manifold.htm

There are actually two vacuum hoses to the vacuum advance unit, one from the middle of the can, one from the base. I'm guessing one of them might be getting manifold vacuum, and the other "ported" vacuum (sometimes even more obscurely referred to as "timed" vacuum), via a port just topsides of the throttle plate, so it only sees significant vacuum when the throttle plate starts to open.

I tried the gauge on both ports and recorded the vacuum reading (inches Hg) at different rpm, read off the dashboard rev counter through the windscreen via a scooter mirror tied to the steering wheel.

rpm 600 800 1000 1100 1200 1400 1500 2000

mid vac 2 3 4 5 7 15

base vac 13*** 12** 12* 12 12.5

(Apparently tabs don't work. Lined up in the original)

From this I'd guess the mid vac is "ported" and the base is manifold. The * represent the oscillation of the needle.

I don't know how this works. Wikipedia has

https://en.wikipedia.org/wiki/Ignition_timing

"Some vacuum advance units have two vacuum connections, one at each side of the actuator membrane, connected to both manifold vacuum and ported vacuum. These units will both advance and retard the ignition timing."

Not sure why (or if) this one would be retarding the ignition. The CB-23 spec says centrifugal advance 0 degrees at 750 rpm. 10.5 degrees at 2.800 rpm vacuum advance 0 degrees at 100 mmHg, 11 degrees at 320 rnmHg, and doesn't seem to mention retardation.

I used my brake-bleeding enema syringe to apply 12"Hg vacuum to the distributor, "calibrating" it with the vacuum gauge, as below. After holding for 30 secs, if the piston returned most of the way, it was considered to be holding vacuum.

Piston displacement (mls) 10 20 30 40 50 60

Pressure (-)("Hg) 7 12 15.5 18 19.5 21

The base vac isn't holding vacuum, but if the tube is reversed, or my brake-bleeding tube substituted, it holds.

This suggests it may be the tube, (which looks OK) rather than the advance can, that is faulty, which would be a cheap fix IF its all that's wrong.

I'll need to use the timing light to confirm (or deny) that the vacuum advance is defective. My new old-stock timing light flashes but I couldn't see the mark. Will try again tommorrow, maybe with tipex etc.

Assuming its faulty, pending repair or replacement of the distributor, I'm wondering about my scope for quick and dirty work-arounds to (maybe) get through the overdue inspection.

I can block off the vacuum advance port to eliminate the vacuum leak.

Would it be worth cautiously advancing the static timing a bit?

I think the emissions test is only done at idle.

I tried using a vacuum gauge that I bought in Japan, to tune the idle. So far I can't see its much better than tuning by ear, but it did "accidentally" give me some info.

I wasn't sure where to plug it in, and tried one of the vacuum advance hoses to the distributor.

I noticed that the idle was steadier while doing this. Possible explanations include:-

(a) There is a vacuum leak via the vacuum advance circuit, perhaps due to a hole in its diaphragm. This will disturb the idle.

(b) As a result of (a), the vacuum advance doesn't work, so the spark happens late. This will disturb the idle too.

http://chevellestuff.net/tech/articles/vacuum/port_or_manifold.htm

There are actually two vacuum hoses to the vacuum advance unit, one from the middle of the can, one from the base. I'm guessing one of them might be getting manifold vacuum, and the other "ported" vacuum (sometimes even more obscurely referred to as "timed" vacuum), via a port just topsides of the throttle plate, so it only sees significant vacuum when the throttle plate starts to open.

I tried the gauge on both ports and recorded the vacuum reading (inches Hg) at different rpm, read off the dashboard rev counter through the windscreen via a scooter mirror tied to the steering wheel.

rpm 600 800 1000 1100 1200 1400 1500 2000

mid vac 2 3 4 5 7 15

base vac 13*** 12** 12* 12 12.5

(Apparently tabs don't work. Lined up in the original)

From this I'd guess the mid vac is "ported" and the base is manifold. The * represent the oscillation of the needle.

I don't know how this works. Wikipedia has

https://en.wikipedia.org/wiki/Ignition_timing

"Some vacuum advance units have two vacuum connections, one at each side of the actuator membrane, connected to both manifold vacuum and ported vacuum. These units will both advance and retard the ignition timing."

Not sure why (or if) this one would be retarding the ignition. The CB-23 spec says centrifugal advance 0 degrees at 750 rpm. 10.5 degrees at 2.800 rpm vacuum advance 0 degrees at 100 mmHg, 11 degrees at 320 rnmHg, and doesn't seem to mention retardation.

I used my brake-bleeding enema syringe to apply 12"Hg vacuum to the distributor, "calibrating" it with the vacuum gauge, as below. After holding for 30 secs, if the piston returned most of the way, it was considered to be holding vacuum.

Piston displacement (mls) 10 20 30 40 50 60

Pressure (-)("Hg) 7 12 15.5 18 19.5 21

The base vac isn't holding vacuum, but if the tube is reversed, or my brake-bleeding tube substituted, it holds.

This suggests it may be the tube, (which looks OK) rather than the advance can, that is faulty, which would be a cheap fix IF its all that's wrong.

I'll need to use the timing light to confirm (or deny) that the vacuum advance is defective. My new old-stock timing light flashes but I couldn't see the mark. Will try again tommorrow, maybe with tipex etc.

Assuming its faulty, pending repair or replacement of the distributor, I'm wondering about my scope for quick and dirty work-arounds to (maybe) get through the overdue inspection.

I can block off the vacuum advance port to eliminate the vacuum leak.

Would it be worth cautiously advancing the static timing a bit?

I think the emissions test is only done at idle.

Last edited: