JHZR2

Staff member

Originally Posted By: Brad_C

Originally Posted By: Gasbuggy

I have a 92 Yukon Coupe that has a R12 system in need of charge. How do I connect propane to it?

A) You don't.

B) If you need to ask then you have much homework to do.

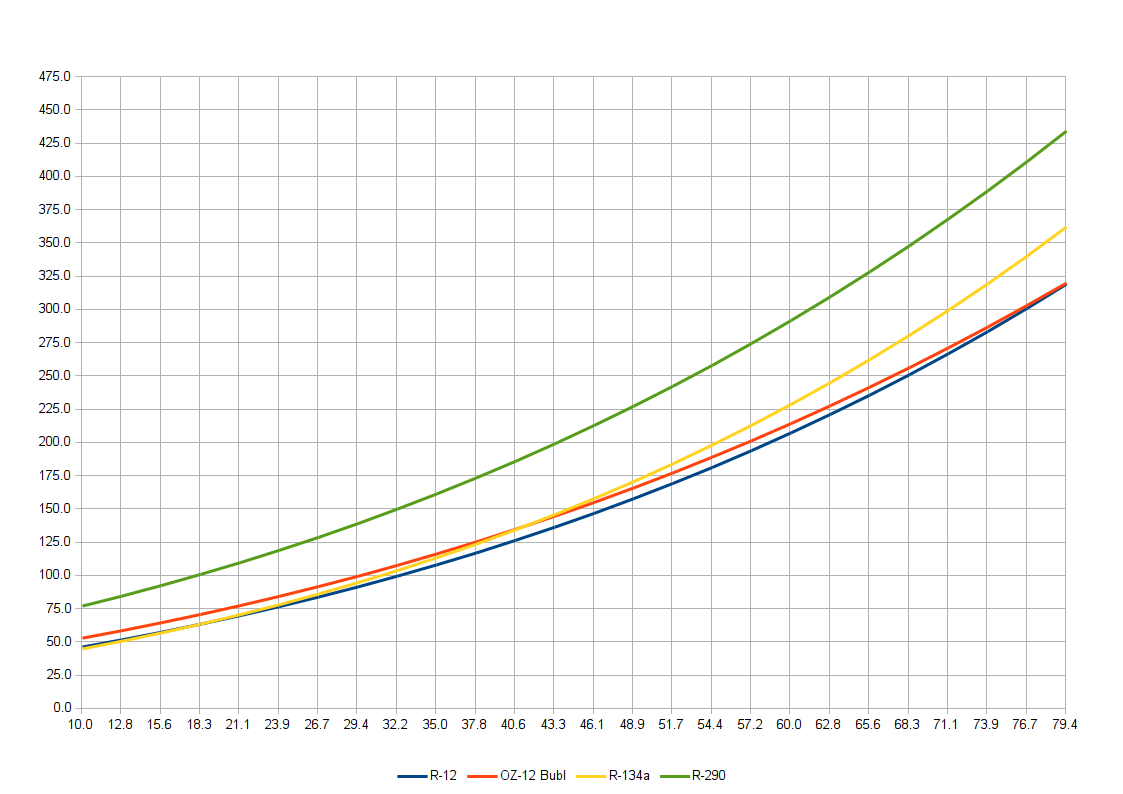

Pure propane has a much higher pressure curve than R12 and in hot climates may well cause rupture damage to the system. Appropriate HC refrigerants are a blend (usually of Propane & iso-Butane) which are mixed to lower the system pressure to that roughly matching R12. R290 is pure Propane.

In this chart OZ-12 represents approximately a 60/40 mix of R290/R600a (Propane/iso-Butane).

Y Axis is PSI. X Axis is temperature (C).

You can see on a hot day when condensing at 60C (pretty normal). Propane is about 100PSI up on R12. Not good.

The problem with blends is that there is a possibility of the more volatile species to escape at a faster rate than the other one. Then what?

Evacuating an HFC system is what scares me most - no shop is going to do it, and release to the air is a huge danger. Vacuuming it down is also a concern.

Originally Posted By: Gasbuggy

I have a 92 Yukon Coupe that has a R12 system in need of charge. How do I connect propane to it?

A) You don't.

B) If you need to ask then you have much homework to do.

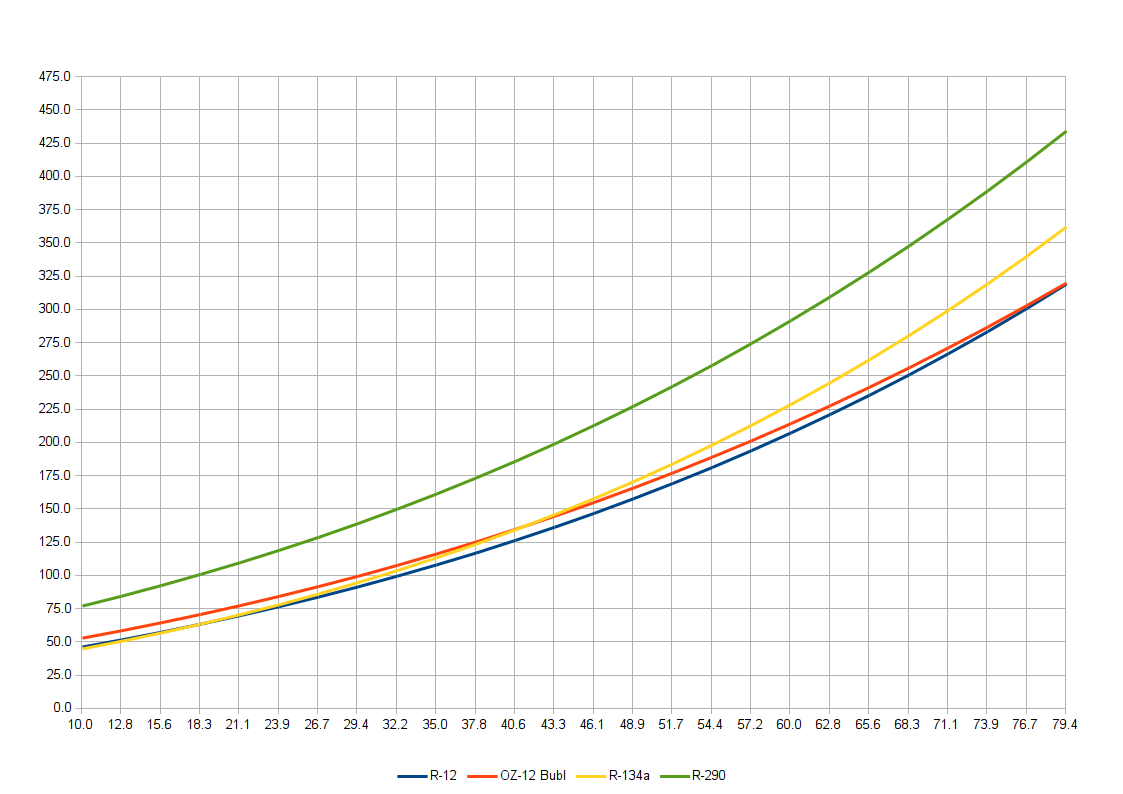

Pure propane has a much higher pressure curve than R12 and in hot climates may well cause rupture damage to the system. Appropriate HC refrigerants are a blend (usually of Propane & iso-Butane) which are mixed to lower the system pressure to that roughly matching R12. R290 is pure Propane.

In this chart OZ-12 represents approximately a 60/40 mix of R290/R600a (Propane/iso-Butane).

Y Axis is PSI. X Axis is temperature (C).

You can see on a hot day when condensing at 60C (pretty normal). Propane is about 100PSI up on R12. Not good.

The problem with blends is that there is a possibility of the more volatile species to escape at a faster rate than the other one. Then what?

Evacuating an HFC system is what scares me most - no shop is going to do it, and release to the air is a huge danger. Vacuuming it down is also a concern.