- Joined

- Oct 21, 2015

- Messages

- 233

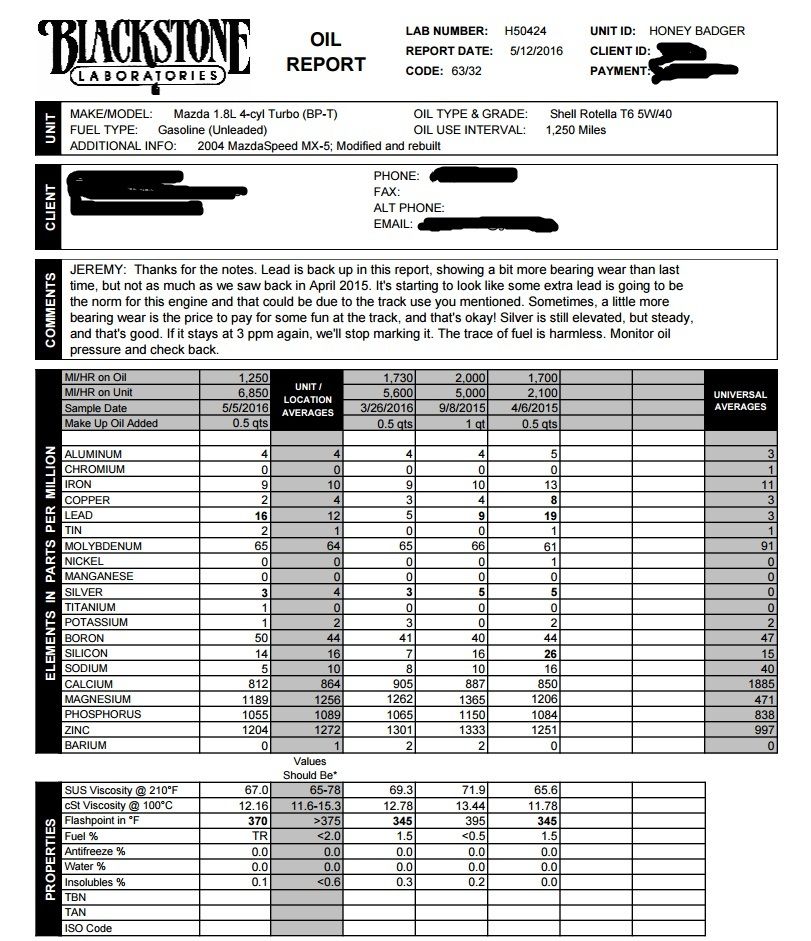

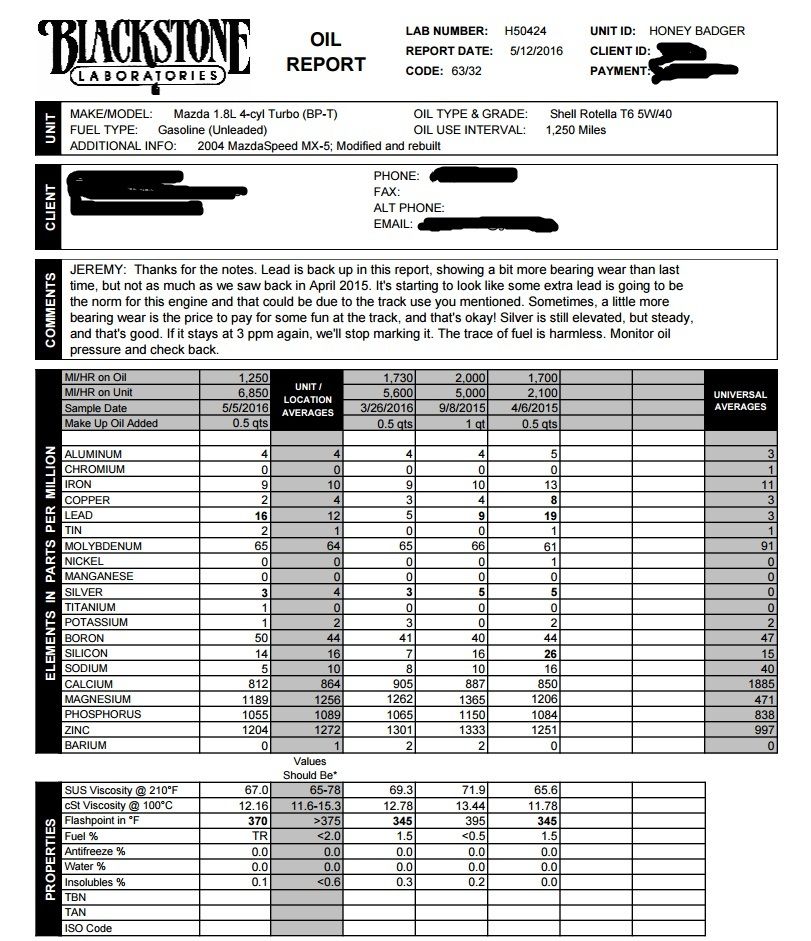

Hey guys so I've been running T6 since basically the start of my rebuild which has been about 7k miles ago. I recently started attending track events (so fun) and have done 2 so far (one whole, one half day). On this particular oil change, I have 1.5 hours of solid beating on the car, which in non turbo form made less than half of the power it does now, actually probably a third. The mod list is extensive, but for the stuff that should matter for this, I am using ACL Race bearings on mains and rods, clearanced at .002. I have a Boundary Engineering oil pump with no shims (I believe its set to open around 55-65psi). Oil is Rotella T6, oil filter was a Mobil 1 #3233. I also run a Setrab oil cooler on the car, using a thermostat sandwich plate which opens at 180 or 190*. I do not have a real oil pressure gauge or oil temp gauge on the car, but at the end of a 20 minute run, my oil pressure gauge dips slightly lower than normal, then levels back up in about 5 minutes. My gauge is a moving needle with lines, but they are not numbered. It's a good reference system, just doesn't provide any concrete data, but I can see my pressure slightly drop when my massive radiator fan kicks on, so it does work in its own way

Here is a cutaway of the bearings (cant get the image to embed, sorry)

https://www.mdspares.com.au/images/1242/bearing-materials.jpg?cache=20141123210950

Lead is elevated, but copper and tin, which are both part of that fatigue layer, are right in line with universal averages. Just looking to get some feedback on how the wear is in your opinions. I was considering trying 10w-40 Castrol EDGE with Titanium next time around and doing another 1250 mile run with about 1-2 track hours to see how it compares.

Here is a cutaway of the bearings (cant get the image to embed, sorry)

https://www.mdspares.com.au/images/1242/bearing-materials.jpg?cache=20141123210950

Lead is elevated, but copper and tin, which are both part of that fatigue layer, are right in line with universal averages. Just looking to get some feedback on how the wear is in your opinions. I was considering trying 10w-40 Castrol EDGE with Titanium next time around and doing another 1250 mile run with about 1-2 track hours to see how it compares.

Last edited: