I have read that condemnation limits for iron are up to 150 ppm, whereas for other wear metals, it is more like 30-60 ppm. Why would this be the case? Are the particles of other metals (such as copper or aluminum) harder, or in some other way, more destructive to an engine, than iron?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Condemnation limits different for different metals

- Thread starter paulri

- Start date

- Status

- Not open for further replies.

Originally Posted By: paulri

I have read that condemnation limits for iron are up to 150 ppm, whereas for other wear metals, it is more like 30-60 ppm. Why would this be the case? Are the particles of other metals (such as copper or aluminum) harder, or in some other way, more destructive to an engine, than iron?

100ppm per 10K for cars, 200ppm for trucks is perfectly OK. Al and Pb are real soft, Cu is about the same as Fe, BUT only Si (Silicon sand) is restricted to 30 ppm. Its crystals have real sharp corners and it comes in through the air filter (Even an OEM one), past the rings and into the oil. Only a difficult to fit dual filter bypass system will catch it. Big trucks have those as standard, there is room in a smallish truck, BUT to fit one in a car might involve moving the battery to boot etc.

I have read that condemnation limits for iron are up to 150 ppm, whereas for other wear metals, it is more like 30-60 ppm. Why would this be the case? Are the particles of other metals (such as copper or aluminum) harder, or in some other way, more destructive to an engine, than iron?

100ppm per 10K for cars, 200ppm for trucks is perfectly OK. Al and Pb are real soft, Cu is about the same as Fe, BUT only Si (Silicon sand) is restricted to 30 ppm. Its crystals have real sharp corners and it comes in through the air filter (Even an OEM one), past the rings and into the oil. Only a difficult to fit dual filter bypass system will catch it. Big trucks have those as standard, there is room in a smallish truck, BUT to fit one in a car might involve moving the battery to boot etc.

Last edited:

- Joined

- Sep 26, 2010

- Messages

- 9,807

While the condemnation limit for iron (as an example) may be 100-150ppm, I would have a problem with that level long before it climbed that high. **Typically**, I have seen all levels to be lower than universal averages in most UOAs which makes one wonder about the engines that cause the universal levels to be what they are. In the Ford Modular family, my engine only exceeded the universal averages when I was more than double (and in some cases triple) the mileage for the universal average. I have to think that my engine is not special and many of the same engines wear the same. It seems strange that a number of them are so vastly different and push the averages to where they are.

Originally Posted By: Shannow

Look at the areas for wear...

Take a cylinder, and there's a massive area for wear to take place versus the rings and bearings.

Shannow, I think you're assuming I know a lot more about cars and oil than I actually do.

So can you please break that down for me---how that pertains to wear metals and condemnation limits? Thanks.

Look at the areas for wear...

Take a cylinder, and there's a massive area for wear to take place versus the rings and bearings.

Shannow, I think you're assuming I know a lot more about cars and oil than I actually do.

So can you please break that down for me---how that pertains to wear metals and condemnation limits? Thanks.

Last edited:

- Joined

- Oct 28, 2014

- Messages

- 1,187

Have no idea where you read that, I disagree. I would change my oil with 75 ppm iron; but that's my personal judgment. The two worst things you can have in your oil are Iron and Silicon. Iron is your engine (literally and microscopically) disintegrating, and Silicon is rock, harder than iron. Most test labs like Blackstone and Polaris caution over 20 ppm Si. Silicon usually comes in thru the air intake. Iron (Fe) ppm can be divided by the number of miles on the oil (in thousands) to determine a wear rate.

http://www.bobistheoilguy.com/used-oil-analysis-how-to-decide-what-is-normal/

You may find this interesting reading, gasoline engines are shown in a chart on page 12-13; along with a good amount of information regarding condemning limits: http://www.oil-lab.com/downloads/Petroleum_Technologies.pdf

And yes, common sense tells us that softer metals such as lead, copper, aluminum, tin, cadmium, etc. are more than likely coming from a little bearing wear and are NOT hard enough to damage other engine parts while sloshing around in your oil, whereas iron particles have the potential to further damage your engine.

http://www.bobistheoilguy.com/used-oil-analysis-how-to-decide-what-is-normal/

You may find this interesting reading, gasoline engines are shown in a chart on page 12-13; along with a good amount of information regarding condemning limits: http://www.oil-lab.com/downloads/Petroleum_Technologies.pdf

And yes, common sense tells us that softer metals such as lead, copper, aluminum, tin, cadmium, etc. are more than likely coming from a little bearing wear and are NOT hard enough to damage other engine parts while sloshing around in your oil, whereas iron particles have the potential to further damage your engine.

Originally Posted By: Ihatetochangeoil

Have no idea where you read that, I disagree. I would change my oil with 75 ppm iron; but that's my personal judgment. The two worst things you can have in your oil are Iron and Silicon. Iron is your engine (literally and microscopically) disintegrating, and Silicon is rock, harder than iron. Most test labs like Blackstone and Polaris caution over 20 ppm Si. Silicon usually comes in thru the air intake. Iron (Fe) ppm can be divided by the number of miles on the oil (in thousands) to determine a wear rate.

Really? How big are the particles that show up in a Blackstone analysis? The ones that register on an ICP or AAS.

That 75ppm of iron that shows up is not in itself doing any damage to your engine. It may mean that damage is occurring (which wouldn't be helped by changing the oil), but the elements that show up on the analysis as being in the oil aren't the ones causing the damage.

Have no idea where you read that, I disagree. I would change my oil with 75 ppm iron; but that's my personal judgment. The two worst things you can have in your oil are Iron and Silicon. Iron is your engine (literally and microscopically) disintegrating, and Silicon is rock, harder than iron. Most test labs like Blackstone and Polaris caution over 20 ppm Si. Silicon usually comes in thru the air intake. Iron (Fe) ppm can be divided by the number of miles on the oil (in thousands) to determine a wear rate.

Really? How big are the particles that show up in a Blackstone analysis? The ones that register on an ICP or AAS.

That 75ppm of iron that shows up is not in itself doing any damage to your engine. It may mean that damage is occurring (which wouldn't be helped by changing the oil), but the elements that show up on the analysis as being in the oil aren't the ones causing the damage.

- Joined

- Oct 28, 2014

- Messages

- 1,187

Iron is a wear metal detected with Elemental Analysis by ICP (inductively-coupled plasma), which detects up to 24 metals, measuring less than 10 microns in size, that can be present in used oil due to wear, contamination or additives. Wear Metals include iron, chromium, nickel, aluminum, copper, lead, tin, cadmium, silver, titanium and vanadium. Contaminant Metals include silicon, sodium, and potassium. Multi-Source Metals include molybdenum, antimony, manganese, and lithium. Additive Metals include boron, magnesium, calcium, barium, phosphorous and zinc. Elemental Analysis is instrumental in determining the type and severity of wear occurring within a unit as is performed by both Blackstone and Polaris.

"That 75ppm of iron that shows up is not in itself doing any damage to your engine. It may mean that damage is occurring (which wouldn't be helped by changing the oil), but the elements that show up on the analysis as being in the oil aren't the ones causing the damage."

Really? So 75 ppm iron are OK with what mileage on the oil? Further information and stated conditions please sir.

The comments I posted regarding Iron and Silicon are quotes from Alan Bender, Technical Lab Director at Oil Analyzers. I am a long time customer and I'm sure I can obtain his phone number and I'm sure he would be happy to discuss his positions and reasons with you sir.

"That 75ppm of iron that shows up is not in itself doing any damage to your engine. It may mean that damage is occurring (which wouldn't be helped by changing the oil), but the elements that show up on the analysis as being in the oil aren't the ones causing the damage."

Really? So 75 ppm iron are OK with what mileage on the oil? Further information and stated conditions please sir.

The comments I posted regarding Iron and Silicon are quotes from Alan Bender, Technical Lab Director at Oil Analyzers. I am a long time customer and I'm sure I can obtain his phone number and I'm sure he would be happy to discuss his positions and reasons with you sir.

That makes my point exactly. I used to do AAS plus KF and acid titrations for the fluid power and automotive engineering departments in college. The maximum particle size detectable was related to the residence time in the plasma (and of course the diameter of the aspiration tube into the machine) and I would agree it is less than 10 microns.

Your post said that you would change the oil at 75ppm iron because that iron in the oil was disintegrating and causing damage. What I said (and what your response reinforced) was that the iron and other elements detectable through AAS or ICP analysis is not the material that is damaging the engine. In fact, I'd go as far as saying that the detectable elements in an analysis may be irrelevant in regards to initiating engine damage. It is an indicator but not a cause.

We found that a significant portion of the elements detected by AAS were at the sub-micron level. A critical factor in an oil was the level of water which became acidic due to combustion byproducts. This caused corrosion and those corrosion products were atomic in size but still show up on the analysis.

Bottom line, once the problem is showing up on an AAS or ICP the damage (if any) is already done. Those elements showing up on the analysis aren't the ones then doing further damage, they are too small. An engine that is destroying itself may shed large particles but those are not detectable by analysis. If you are going by "ppm wear metals" alone you would think the engine is running just fine when in fact it may be on the verge of failure. Doing a wash-down of the filter and an examination of the residue under an electron microscope will show you those particles.

Originally Posted By: Ihatetochangeoil

Iron is a wear metal detected with Elemental Analysis by ICP (inductively-coupled plasma), which detects up to 24 metals, measuring less than 10 microns in size, that can be present in used oil due to wear, contamination or additives. Wear Metals include iron, chromium, nickel, aluminum, copper, lead, tin, cadmium, silver, titanium and vanadium. Contaminant Metals include silicon, sodium, and potassium. Multi-Source Metals include molybdenum, antimony, manganese, and lithium. Additive Metals include boron, magnesium, calcium, barium, phosphorous and zinc. Elemental Analysis is instrumental in determining the type and severity of wear occurring within a unit as is performed by both Blackstone and Polaris.

"That 75ppm of iron that shows up is not in itself doing any damage to your engine. It may mean that damage is occurring (which wouldn't be helped by changing the oil), but the elements that show up on the analysis as being in the oil aren't the ones causing the damage."

Really? So 75 ppm iron are OK with what mileage on the oil? Further information and stated conditions please sir.

The comments I posted regarding Iron and Silicon are quotes from Alan Bender, Technical Lab Director at Oil Analyzers. I am a long time customer and I'm sure I can obtain his phone number and I'm sure he would be happy to discuss his positions and reasons with you sir.

Your post said that you would change the oil at 75ppm iron because that iron in the oil was disintegrating and causing damage. What I said (and what your response reinforced) was that the iron and other elements detectable through AAS or ICP analysis is not the material that is damaging the engine. In fact, I'd go as far as saying that the detectable elements in an analysis may be irrelevant in regards to initiating engine damage. It is an indicator but not a cause.

We found that a significant portion of the elements detected by AAS were at the sub-micron level. A critical factor in an oil was the level of water which became acidic due to combustion byproducts. This caused corrosion and those corrosion products were atomic in size but still show up on the analysis.

Bottom line, once the problem is showing up on an AAS or ICP the damage (if any) is already done. Those elements showing up on the analysis aren't the ones then doing further damage, they are too small. An engine that is destroying itself may shed large particles but those are not detectable by analysis. If you are going by "ppm wear metals" alone you would think the engine is running just fine when in fact it may be on the verge of failure. Doing a wash-down of the filter and an examination of the residue under an electron microscope will show you those particles.

Originally Posted By: Ihatetochangeoil

Iron is a wear metal detected with Elemental Analysis by ICP (inductively-coupled plasma), which detects up to 24 metals, measuring less than 10 microns in size, that can be present in used oil due to wear, contamination or additives. Wear Metals include iron, chromium, nickel, aluminum, copper, lead, tin, cadmium, silver, titanium and vanadium. Contaminant Metals include silicon, sodium, and potassium. Multi-Source Metals include molybdenum, antimony, manganese, and lithium. Additive Metals include boron, magnesium, calcium, barium, phosphorous and zinc. Elemental Analysis is instrumental in determining the type and severity of wear occurring within a unit as is performed by both Blackstone and Polaris.

"That 75ppm of iron that shows up is not in itself doing any damage to your engine. It may mean that damage is occurring (which wouldn't be helped by changing the oil), but the elements that show up on the analysis as being in the oil aren't the ones causing the damage."

Really? So 75 ppm iron are OK with what mileage on the oil? Further information and stated conditions please sir.

The comments I posted regarding Iron and Silicon are quotes from Alan Bender, Technical Lab Director at Oil Analyzers. I am a long time customer and I'm sure I can obtain his phone number and I'm sure he would be happy to discuss his positions and reasons with you sir.

The wear metal analysis as mentioned above only detects a certain size of particles. There are larger particles present and the number you get from ICP or other AES methods is only indicative of a trend; not an absolute value. Since there are a lot more iron contact points, indications of excessive wear will show up in the iron count at a faster rate than the other metals most of the time.

Obviously if it is ring wear or something specific like that, the numbers would tell a different story, but if you are looking at them as indications of general wear, the breaking point of iron is higher than the others because of the total content. For an indication of general wear and contamination of wear metals, 150 ppm (or 75 ppm, whatever limit you want) will correspond to lower numbers of the other metals for that reason. If it were all aluminum, then the aluminum number would be the higher number in general.

This is how I have always understood it, but I'll readily admit I don't do a lot of UOA work. So if someone can explain it better than me, please do.

And to reaffirm UltraFanUK's response, yes a number of the other metals are softer than iron and therefore, are less of a risk to cause surface wear or scoring. Whereas the Si number is very important when it relates to dirt since it is very damaging to surfaces.

Obviously if it is ring wear or something specific like that, the numbers would tell a different story, but if you are looking at them as indications of general wear, the breaking point of iron is higher than the others because of the total content. For an indication of general wear and contamination of wear metals, 150 ppm (or 75 ppm, whatever limit you want) will correspond to lower numbers of the other metals for that reason. If it were all aluminum, then the aluminum number would be the higher number in general.

This is how I have always understood it, but I'll readily admit I don't do a lot of UOA work. So if someone can explain it better than me, please do.

And to reaffirm UltraFanUK's response, yes a number of the other metals are softer than iron and therefore, are less of a risk to cause surface wear or scoring. Whereas the Si number is very important when it relates to dirt since it is very damaging to surfaces.

Originally Posted By: MotoTribologist

And to reaffirm UltraFanUK's response, yes a number of the other metals are softer than iron and therefore, are less of a risk to cause surface wear or scoring. Whereas the Si number is very important when it relates to dirt since it is very damaging to surfaces.

I've always wondered, can you even measure the silicon fro SiO2 using ICP or AAS without a HF digestion? I'm not sure if you can or not.

And to reaffirm UltraFanUK's response, yes a number of the other metals are softer than iron and therefore, are less of a risk to cause surface wear or scoring. Whereas the Si number is very important when it relates to dirt since it is very damaging to surfaces.

I've always wondered, can you even measure the silicon fro SiO2 using ICP or AAS without a HF digestion? I'm not sure if you can or not.

Originally Posted By: MotoTribologist

And to reaffirm UltraFanUK's response, yes a number of the other metals are softer than iron and therefore, are less of a risk to cause surface wear or scoring.

Only if the sizes that are capable of being detected cause additional wear, which the text from Oil Analyzers would indicate it is not.

If I dissolved a gram of iron in nitric acid and then put that solution into the oil you would get large numbers for Fe on an analysis but none of that iron would do any harm to the engine. If on the other hand I put a gram of iron filings larger than approximately 10 microns into the engine, the potential for harm would be great but none of that iron would show up on an analysis. Considering the upper size bound for particle detection via AAS or ICP I don't see how it translates into a condemnation limit for the oil (but it certainly may for the engine).

And to reaffirm UltraFanUK's response, yes a number of the other metals are softer than iron and therefore, are less of a risk to cause surface wear or scoring.

Only if the sizes that are capable of being detected cause additional wear, which the text from Oil Analyzers would indicate it is not.

If I dissolved a gram of iron in nitric acid and then put that solution into the oil you would get large numbers for Fe on an analysis but none of that iron would do any harm to the engine. If on the other hand I put a gram of iron filings larger than approximately 10 microns into the engine, the potential for harm would be great but none of that iron would show up on an analysis. Considering the upper size bound for particle detection via AAS or ICP I don't see how it translates into a condemnation limit for the oil (but it certainly may for the engine).

Originally Posted By: kschachn

Originally Posted By: MotoTribologist

And to reaffirm UltraFanUK's response, yes a number of the other metals are softer than iron and therefore, are less of a risk to cause surface wear or scoring.

Only if the sizes that are capable of being detected cause additional wear, which the text from Oil Analyzers would indicate it is not.

If I dissolved a gram of iron in nitric acid and then put that solution into the oil you would get large numbers for Fe on an analysis but none of that iron would do any harm to the engine. If on the other hand I put a gram of iron filings larger than approximately 10 microns into the engine, the potential for harm would be great but none of that iron would show up on an analysis. Considering the upper size bound for particle detection via AAS or ICP I don't see how it translates into a condemnation limit for the oil (but it certainly may for the engine).

But again, the numbers are only indicative of the true value, and not an absolute value. If there are more sub 10 micron particles present, there are theoretically more larger particles as well. It isn't perfect, but its the best we have. Combined with analytical ferrography you can get a pretty good estimation of the true contaminant condition.

Originally Posted By: MotoTribologist

And to reaffirm UltraFanUK's response, yes a number of the other metals are softer than iron and therefore, are less of a risk to cause surface wear or scoring.

Only if the sizes that are capable of being detected cause additional wear, which the text from Oil Analyzers would indicate it is not.

If I dissolved a gram of iron in nitric acid and then put that solution into the oil you would get large numbers for Fe on an analysis but none of that iron would do any harm to the engine. If on the other hand I put a gram of iron filings larger than approximately 10 microns into the engine, the potential for harm would be great but none of that iron would show up on an analysis. Considering the upper size bound for particle detection via AAS or ICP I don't see how it translates into a condemnation limit for the oil (but it certainly may for the engine).

But again, the numbers are only indicative of the true value, and not an absolute value. If there are more sub 10 micron particles present, there are theoretically more larger particles as well. It isn't perfect, but its the best we have. Combined with analytical ferrography you can get a pretty good estimation of the true contaminant condition.

Originally Posted By: MotoTribologist

But again, the numbers are only indicative of the true value, and not an absolute value. If there are more sub 10 micron particles present, there are theoretically more larger particles as well. It isn't perfect, but its the best we have. Combined with analytical ferrography you can get a pretty good estimation of the true contaminant condition.

Without an oil filter there would likely be a bell-shaped distribution curve. But that's not the case, and even a filter with low efficiency will trap sub 20 micron particles especially near the end of an OCI.

But again, the numbers are only indicative of the true value, and not an absolute value. If there are more sub 10 micron particles present, there are theoretically more larger particles as well. It isn't perfect, but its the best we have. Combined with analytical ferrography you can get a pretty good estimation of the true contaminant condition.

Without an oil filter there would likely be a bell-shaped distribution curve. But that's not the case, and even a filter with low efficiency will trap sub 20 micron particles especially near the end of an OCI.

Originally Posted By: kschachn

Originally Posted By: MotoTribologist

But again, the numbers are only indicative of the true value, and not an absolute value. If there are more sub 10 micron particles present, there are theoretically more larger particles as well. It isn't perfect, but its the best we have. Combined with analytical ferrography you can get a pretty good estimation of the true contaminant condition.

Without an oil filter there would likely be a bell-shaped distribution curve. But that's not the case, and even a filter with low efficiency will trap sub 20 micron particles especially near the end of an OCI.

I totally agree.

Originally Posted By: MotoTribologist

But again, the numbers are only indicative of the true value, and not an absolute value. If there are more sub 10 micron particles present, there are theoretically more larger particles as well. It isn't perfect, but its the best we have. Combined with analytical ferrography you can get a pretty good estimation of the true contaminant condition.

Without an oil filter there would likely be a bell-shaped distribution curve. But that's not the case, and even a filter with low efficiency will trap sub 20 micron particles especially near the end of an OCI.

I totally agree.

- Joined

- Oct 28, 2014

- Messages

- 1,187

We're getting a little off topic. The OPs question was Condemnation limits for different metals, not particle sizes or the capabilities of ICP or AAS...

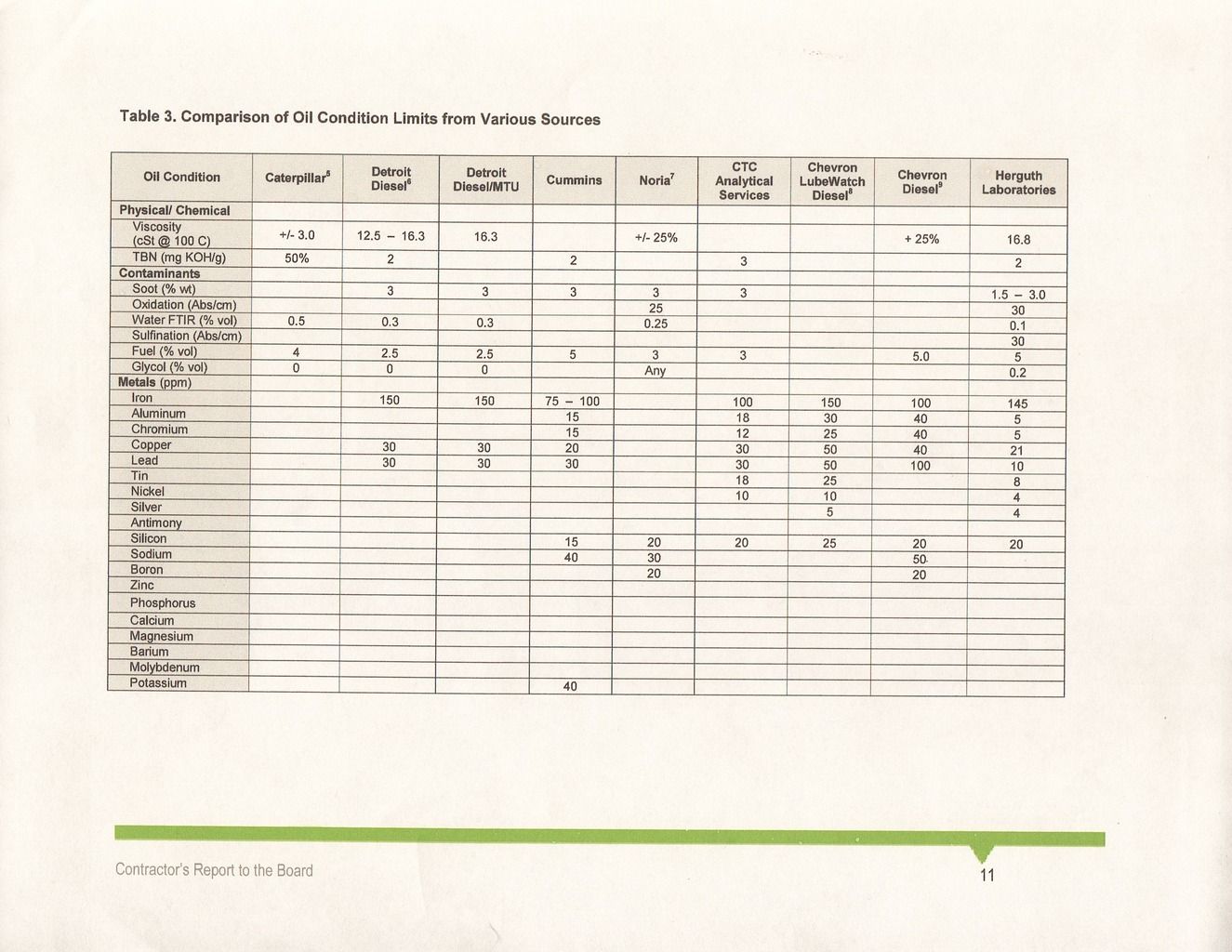

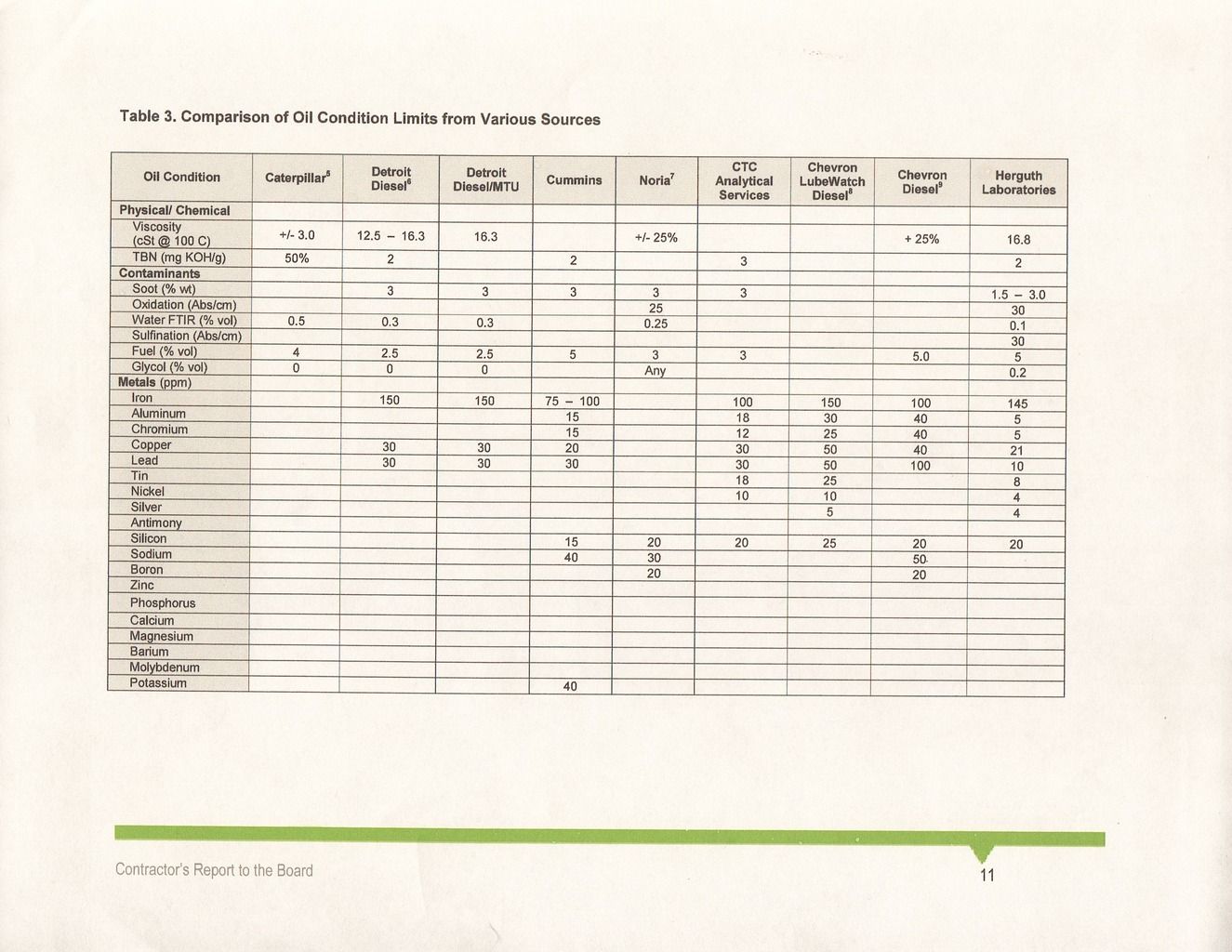

With that in mind, I located among my resources a chart of condemning limits from different sources; and I might say to the OP that such condemning limits from OEMs are rather hard to come by; I think Ford, General Motors, Honda, etc., would rather us buy another new car than the general public become aware of their planned obsolescence, but I digress.

And it is completely on topic for me to say I disagree with everything that UltrafanUK stated regarding condemning limits. If you think 100ppm per 10K for cars is OK and 200 ppm for trucks is OK, rendering wear rates of 10 or 20?? If you consider a wear rate of 10 or 20 normal, perhaps you need to reread this:

http://www.bobistheoilguy.com/used-oil-analysis-how-to-decide-what-is-normal/

My opinion would be that with a wear rate of 10 or 20, there is a mechanical issue that needs to be investigated. Perhaps a rocker arm bolt coming loose? Just speculation, but the point is that 10 or 20 for a wear rate is not normal.

And then read pp 12-13 here for condemning limits: http://www.oil-lab.com/downloads/Petroleum_Technologies.pdf

With that in mind, I located among my resources a chart of condemning limits from different sources; and I might say to the OP that such condemning limits from OEMs are rather hard to come by; I think Ford, General Motors, Honda, etc., would rather us buy another new car than the general public become aware of their planned obsolescence, but I digress.

And it is completely on topic for me to say I disagree with everything that UltrafanUK stated regarding condemning limits. If you think 100ppm per 10K for cars is OK and 200 ppm for trucks is OK, rendering wear rates of 10 or 20?? If you consider a wear rate of 10 or 20 normal, perhaps you need to reread this:

http://www.bobistheoilguy.com/used-oil-analysis-how-to-decide-what-is-normal/

My opinion would be that with a wear rate of 10 or 20, there is a mechanical issue that needs to be investigated. Perhaps a rocker arm bolt coming loose? Just speculation, but the point is that 10 or 20 for a wear rate is not normal.

And then read pp 12-13 here for condemning limits: http://www.oil-lab.com/downloads/Petroleum_Technologies.pdf

A problem with this thread is that the question was made about generic "condemnation limits" but what, exactly was being condemned was not defined. Is it the oil or the engine? That difference is illustrated by your spreadsheet where Noria's limits (presumably for the oil) show oil-related condition limits whereas the manufacturer limits appear to be related to engine health, not oil health. So in that context and related to your assertion that metals as expressed by AAS or ICP are in and of themselves harmful the thread really is not off topic. Your first post that wear metals in the oil were in and of themselves damaging was what prompted the discussion on particle size threshold.

Noria is not concerned with metals in the oil from an oil standpoint whereas the engine manufacturers are. This is because the metal in the oil is representative of the engine health. Those engine manufacturers are establishing UOA limits that reflect an issue with their engines. There is some overlap in silicon but note that this seems to extend to other testing laboratores ("CTC Analytical Services" "Chevron LubeWatch Diesel", "Herguth Laboratories".) In any case, It may very well be that those oil testing facilities have a concern for the engine just by the simple fact that silicon at any level is detrimental.

So you think that Honda, GM and Ford don't have such limits somewhere, possibly available to their dealer network but not to the public? Heavy equipment manufacturers may assume that their operators have a higher probability of performing a used oil analysis than do passenger car owners.

Do you have the footnotes that are referenced in your spreadsheet?

Noria is not concerned with metals in the oil from an oil standpoint whereas the engine manufacturers are. This is because the metal in the oil is representative of the engine health. Those engine manufacturers are establishing UOA limits that reflect an issue with their engines. There is some overlap in silicon but note that this seems to extend to other testing laboratores ("CTC Analytical Services" "Chevron LubeWatch Diesel", "Herguth Laboratories".) In any case, It may very well be that those oil testing facilities have a concern for the engine just by the simple fact that silicon at any level is detrimental.

So you think that Honda, GM and Ford don't have such limits somewhere, possibly available to their dealer network but not to the public? Heavy equipment manufacturers may assume that their operators have a higher probability of performing a used oil analysis than do passenger car owners.

Do you have the footnotes that are referenced in your spreadsheet?

I don't think there is a problem with this thread. The OP seems happy with the responses and we've exchanged ideas. Is that not the point? I think it is being over-complicated to answer more than the OP asked.

- Status

- Not open for further replies.

Similar threads

- Replies

- 13

- Views

- 796

- Replies

- 26

- Views

- 2K

- Replies

- 9

- Views

- 402

- Replies

- 11

- Views

- 1K