I've had couple of struts apart in order to change the mount/bearing and I used an air/impact gun to install the main retaining nut on top of the strut. Every time I do this the chrome shaft of the strut tends to turn with the nut. Never had one fly apart after this but it doesn't seem right. Anyone had a problem with this? Solutions?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tightening strut bearing/mount to strut difficulty

- Thread starter WobblyElvis

- Start date

- Status

- Not open for further replies.

Some struts will have flats ground in them to hold the shaft while the nut is tightend before installation. On others without that feature, you can tighten the retaining nut to the correct torque once the strut is re-installed and the vehicle lowered onto the suspension. The vehicle weight will compress the assembly and let you tighten it.

Yeah, I've never seen one yet that doesn't have some means of restraining the strut rod from turning as you tighten it to the correct spec. Are you saying yours don't have any means of restraint?

WobblyElvis

Thread starter

The only thing I have seen is the top of the strut is hex shaped to take maybe a 1/2 inch wrench but you would need a special deep socket that allows you to tighten the nut while also holding the shaft. I see on youtube it is common to just use an air gun and be done with it.

I don't see how having the weight of the car compress the strut is going to hold the chrome shaft from spinning.

Am I missing something? [other than brains]

I don't see how having the weight of the car compress the strut is going to hold the chrome shaft from spinning.

Am I missing something? [other than brains]

open side wall socket. Stick allen key/wrench in socket opening and tighten. Maybe Autozone has a rental set?

I bought a set while changing the struts on my son's BMW.

I bought a set while changing the struts on my son's BMW.

Last edited:

Originally Posted By: WobblyElvis

I don't see how having the weight of the car compress the strut is going to hold the chrome shaft from spinning.

Am I missing something? [other than brains]

Most of the weight is born by the spring, some is on the shock. It is more than enough to stabilize it to meet the moderate torque requirements of the retaining nut. It is a technique recommended by some manufacturers (Tokico, fo one).

I don't see how having the weight of the car compress the strut is going to hold the chrome shaft from spinning.

Am I missing something? [other than brains]

Most of the weight is born by the spring, some is on the shock. It is more than enough to stabilize it to meet the moderate torque requirements of the retaining nut. It is a technique recommended by some manufacturers (Tokico, fo one).

This is why I use quick struts

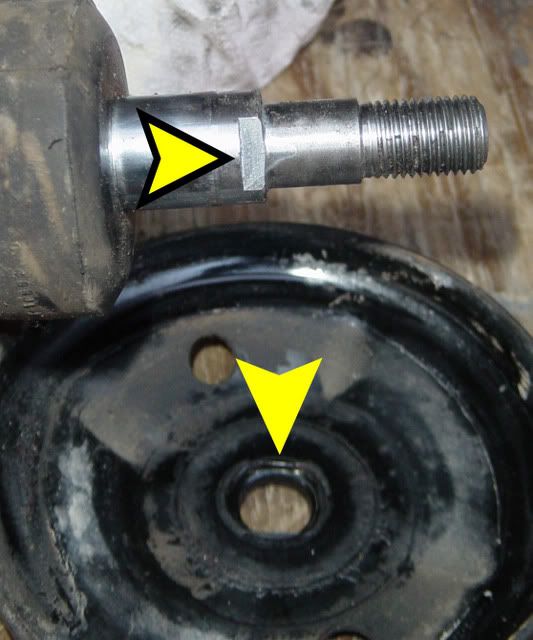

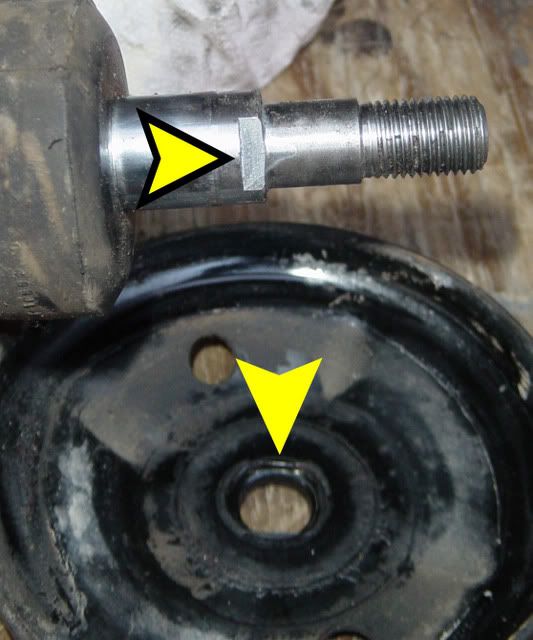

Well the ones on my Toyotas have a flat on the top of the rod that mates with a slot in the strut mount, you then restrain the strut mount from turning with a taped screwdriver between the mount studs. That keeps the rod from turning:

Originally Posted By: WobblyElvis

The only thing I have seen is the top of the strut is hex shaped to take maybe a 1/2 inch wrench but you would need a special deep socket that allows you to tighten the nut while also holding the shaft. I see on youtube it is common to just use an air gun and be done with it.

I don't see how having the weight of the car compress the strut is going to hold the chrome shaft from spinning.

Am I missing something? [other than brains]

Originally Posted By: WobblyElvis

The only thing I have seen is the top of the strut is hex shaped to take maybe a 1/2 inch wrench but you would need a special deep socket that allows you to tighten the nut while also holding the shaft. I see on youtube it is common to just use an air gun and be done with it.

I don't see how having the weight of the car compress the strut is going to hold the chrome shaft from spinning.

Am I missing something? [other than brains]

I've thought of this before too.. How much spinning would it take to ruin the internal seals of the strut??

I don't use and impact for installing. I do put a bit of antiseize on the new strut threads, as it seems to help me torque them down easier by hand. I use an allen and drop end wrench or the drop end wrench and a regular wrench on top depending on the strut.

Some strut mounts don't leave room for a wrench and you need a socket tool to put an allen through, I have not run across it yet.

something like this for those.

http://www.amazon.com/Performance-Tool-W...utomotive&i

Some strut mounts don't leave room for a wrench and you need a socket tool to put an allen through, I have not run across it yet.

something like this for those.

http://www.amazon.com/Performance-Tool-W...utomotive&i

Last edited:

It's one of the reason I prefer Monroe struts. They have a hex (allen hole) on the top that makes it real easy to tighten that nut.

I also love the vintage 1980's Craftsman ratchet.

Also, you really shouldn't be using air tools to tighten this either.

I also love the vintage 1980's Craftsman ratchet.

Also, you really shouldn't be using air tools to tighten this either.

- Status

- Not open for further replies.

Similar threads

- Replies

- 22

- Views

- 2K

- Replies

- 18

- Views

- 931

- Replies

- 139

- Views

- 10K

- Replies

- 6

- Views

- 671