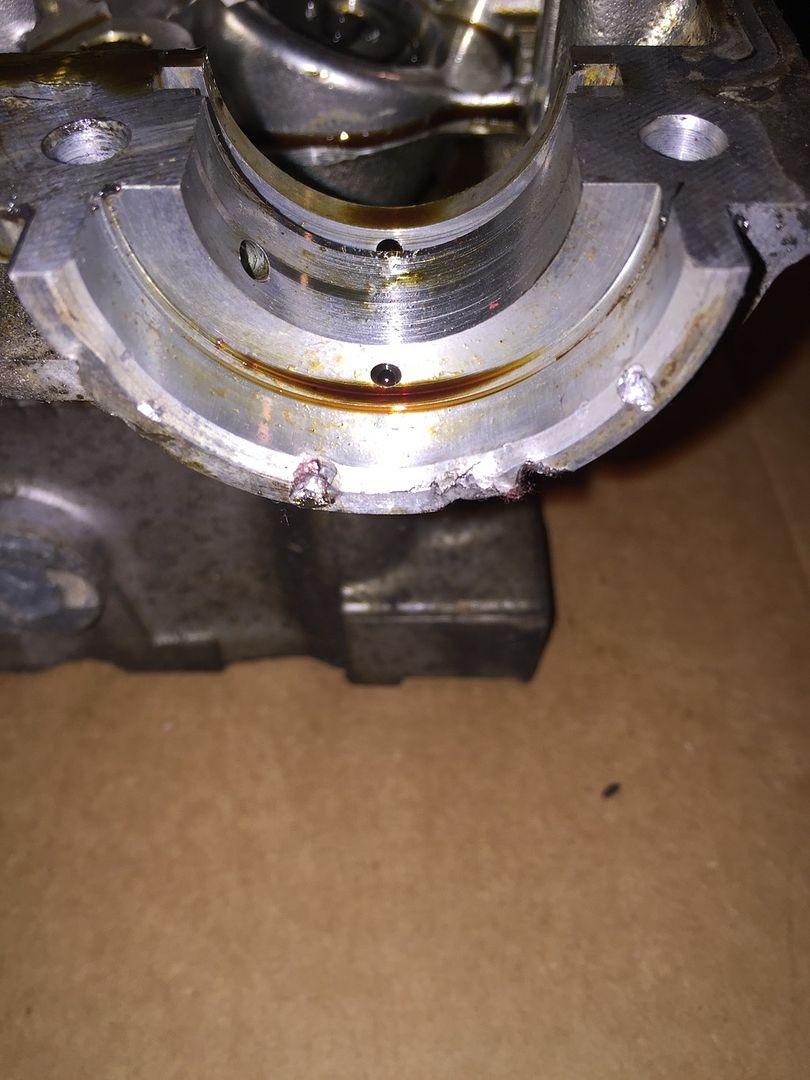

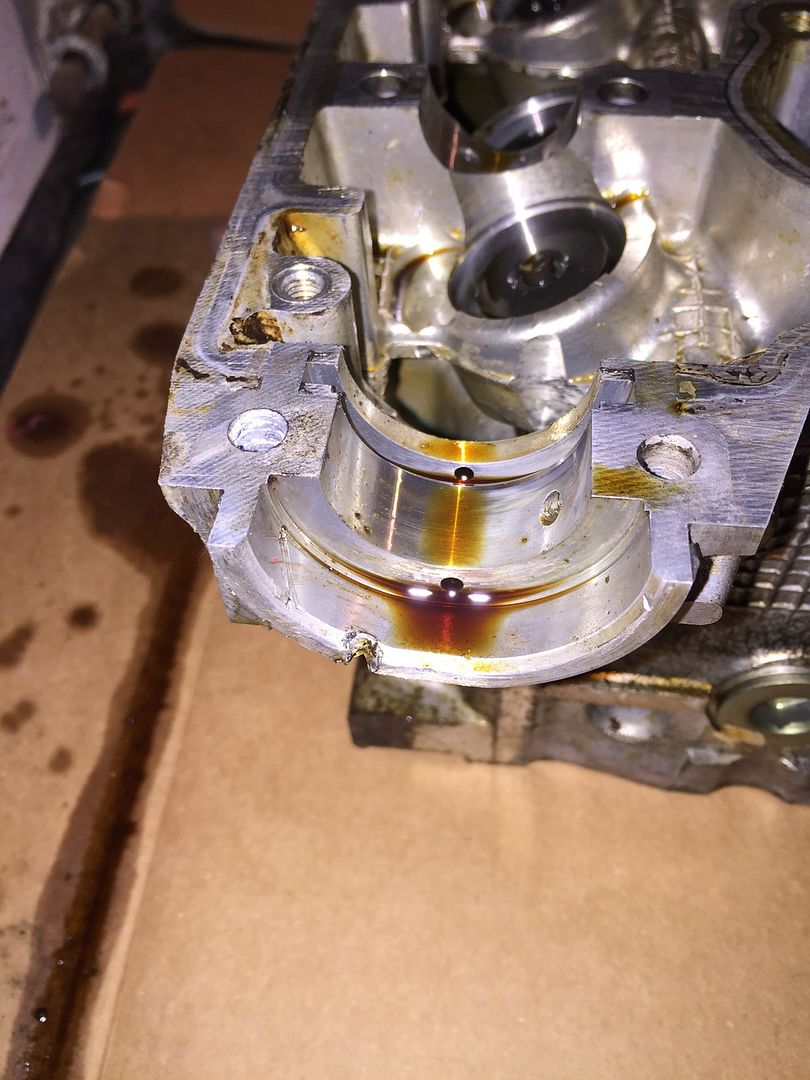

I purchased a 99 Subaru Outback to work on over the winter. One thing it needed was head gaskets. They had been done at some point in the cars life but the quality of the gaskets was questionable.

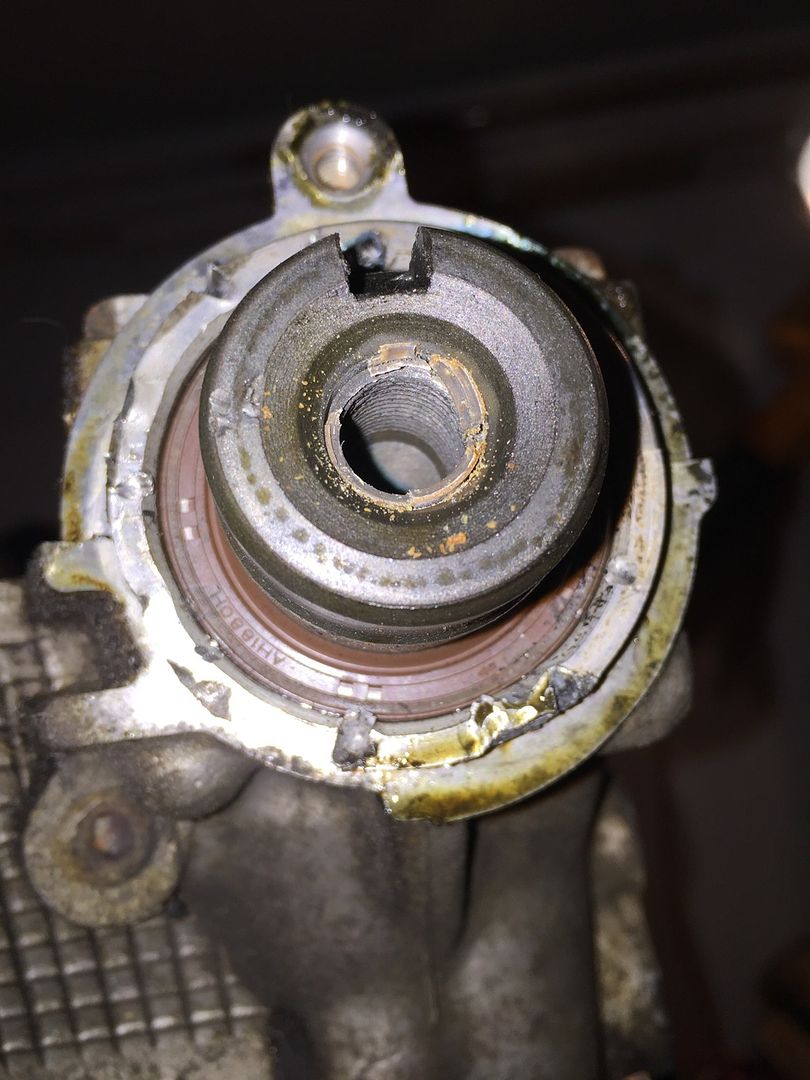

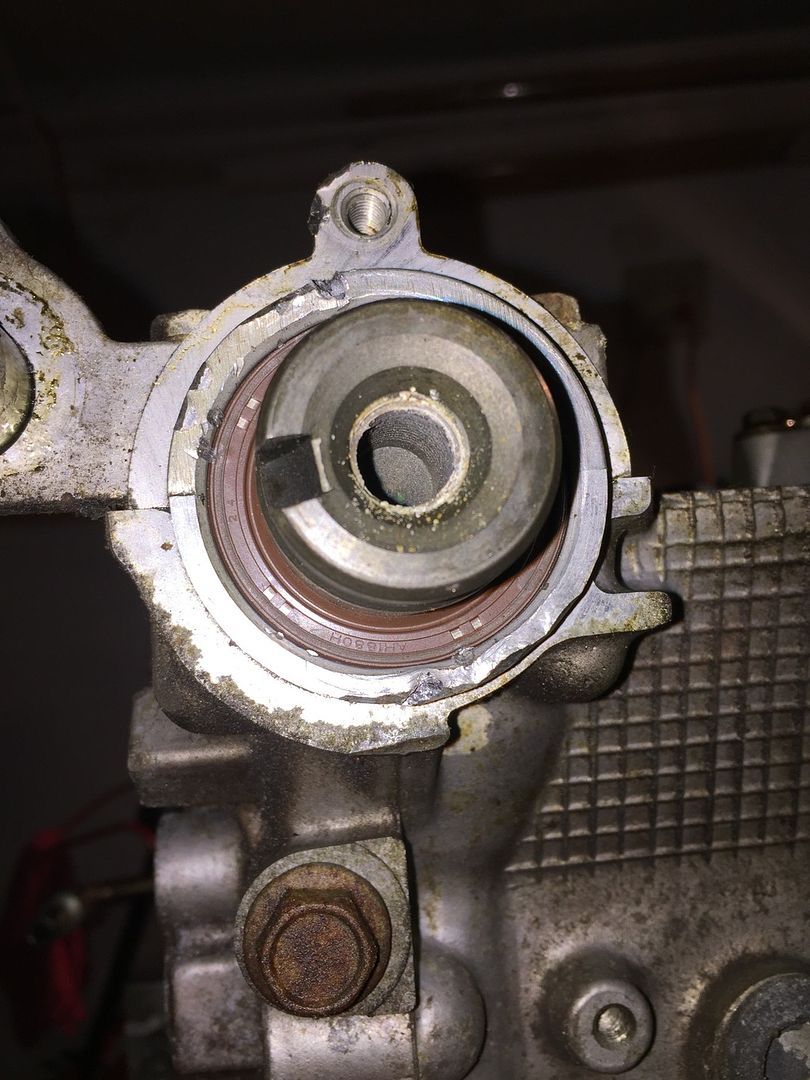

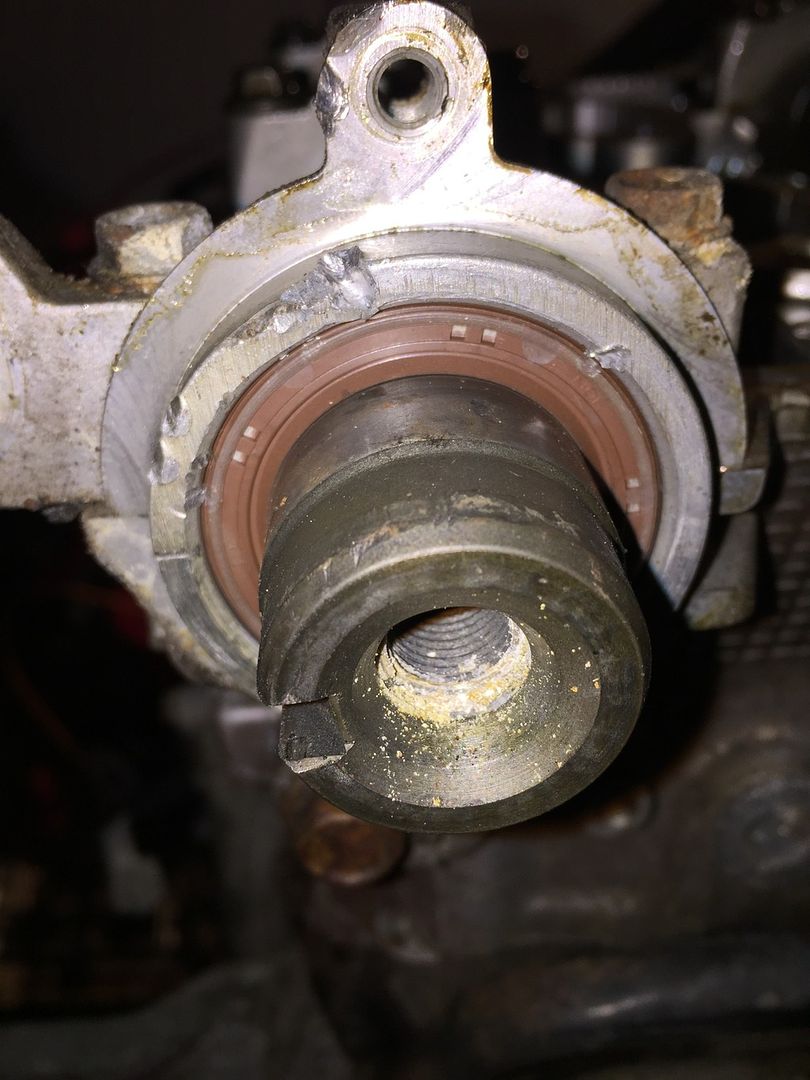

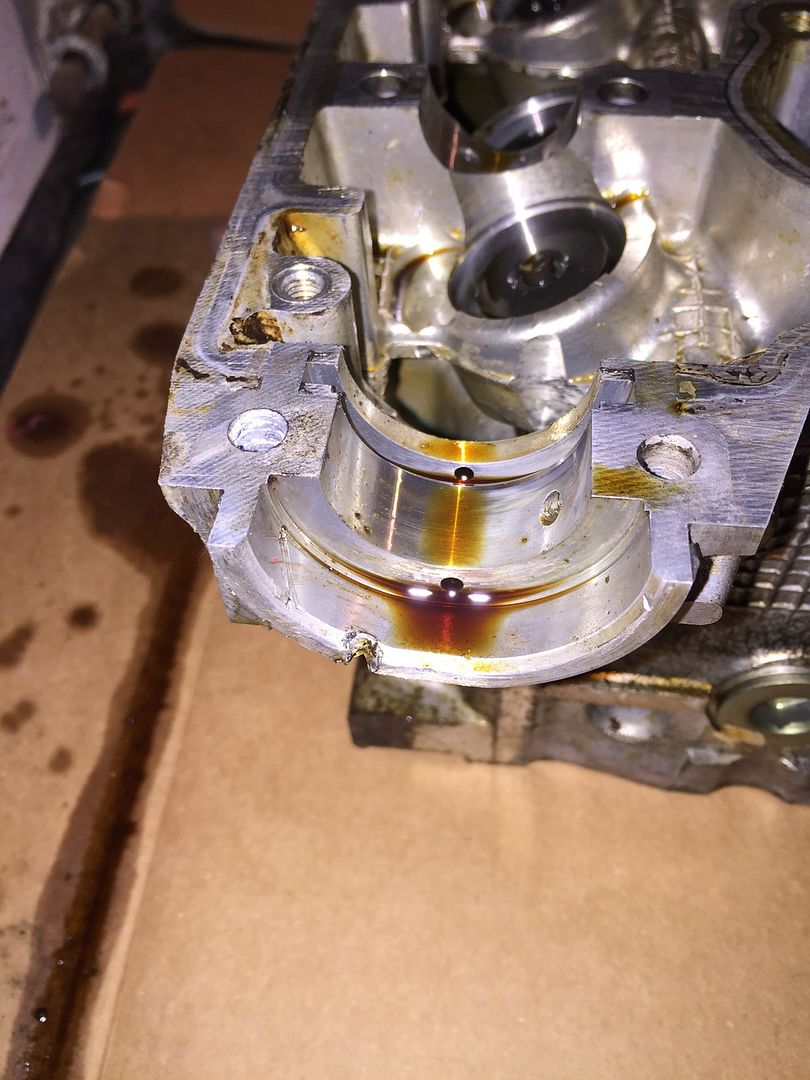

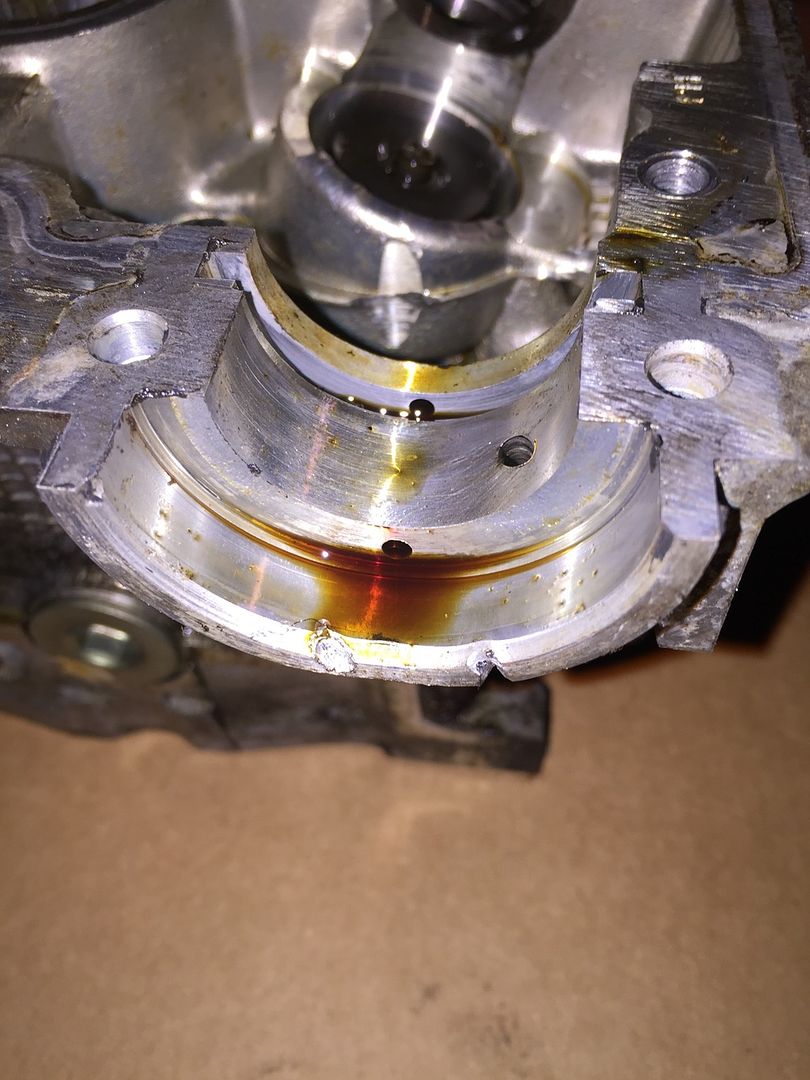

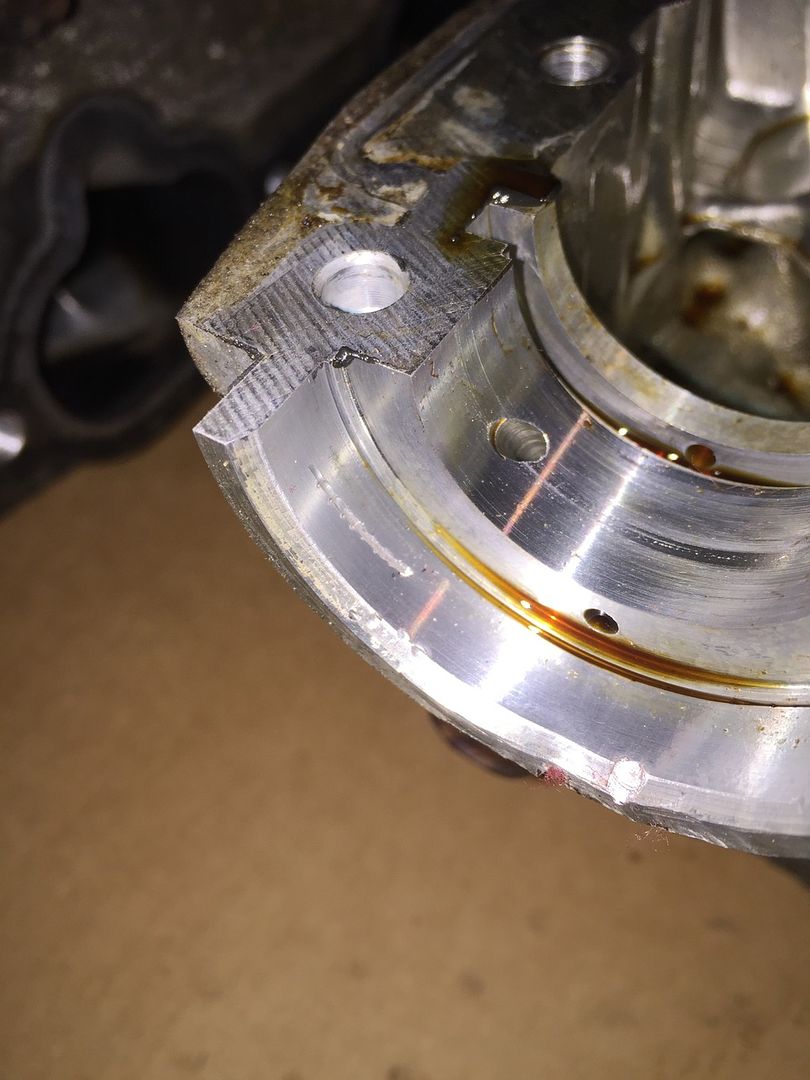

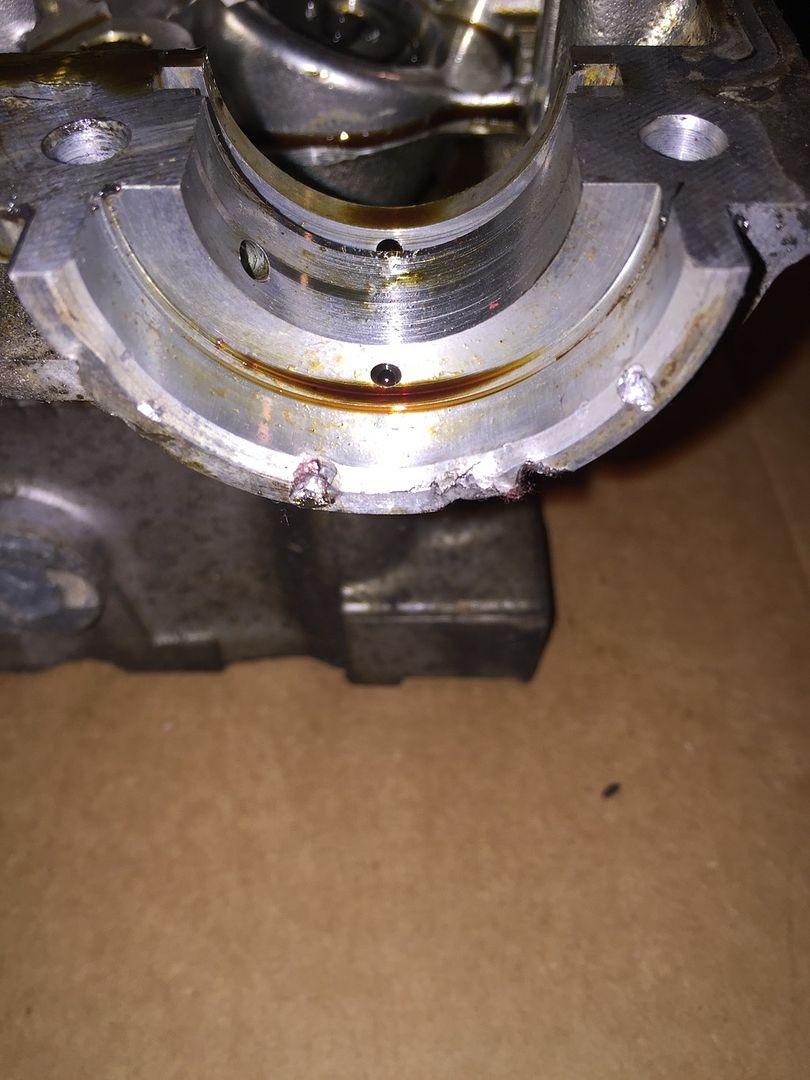

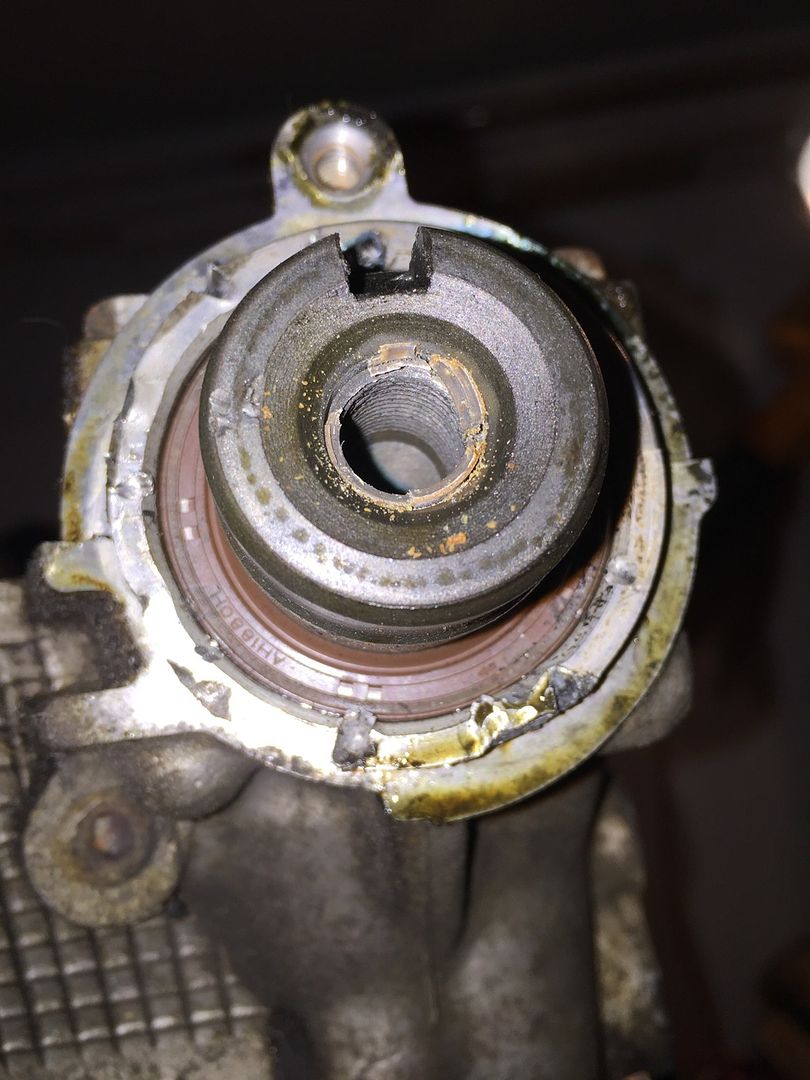

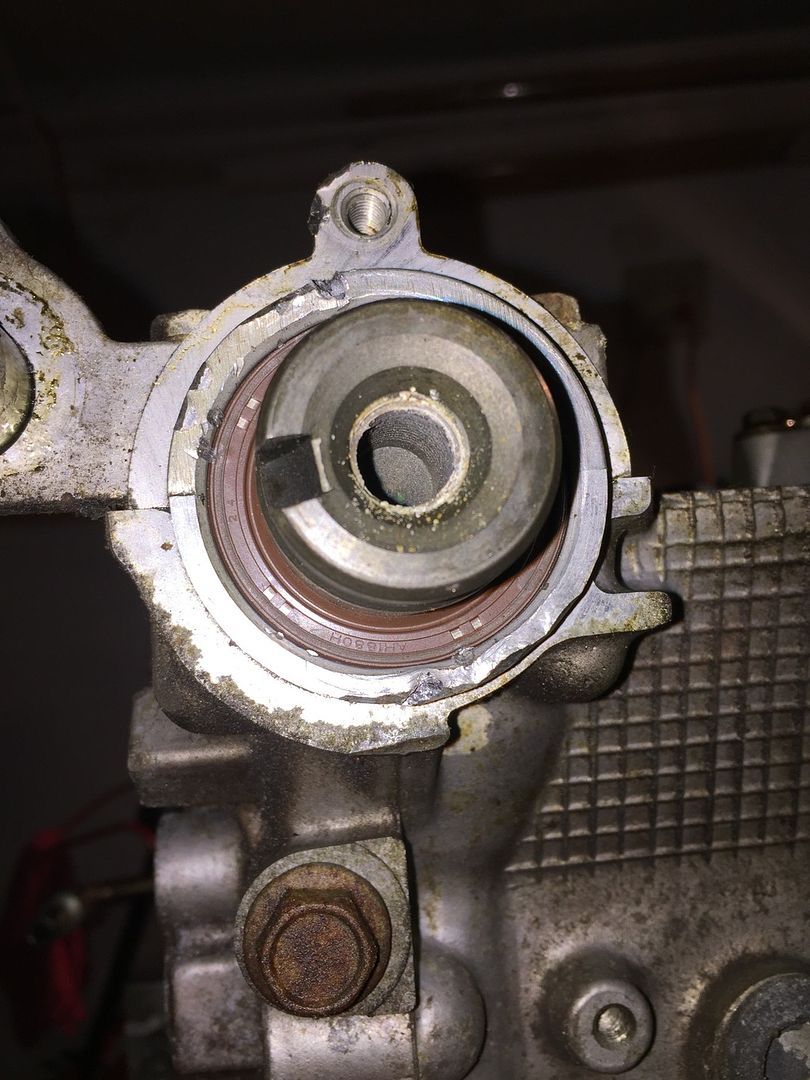

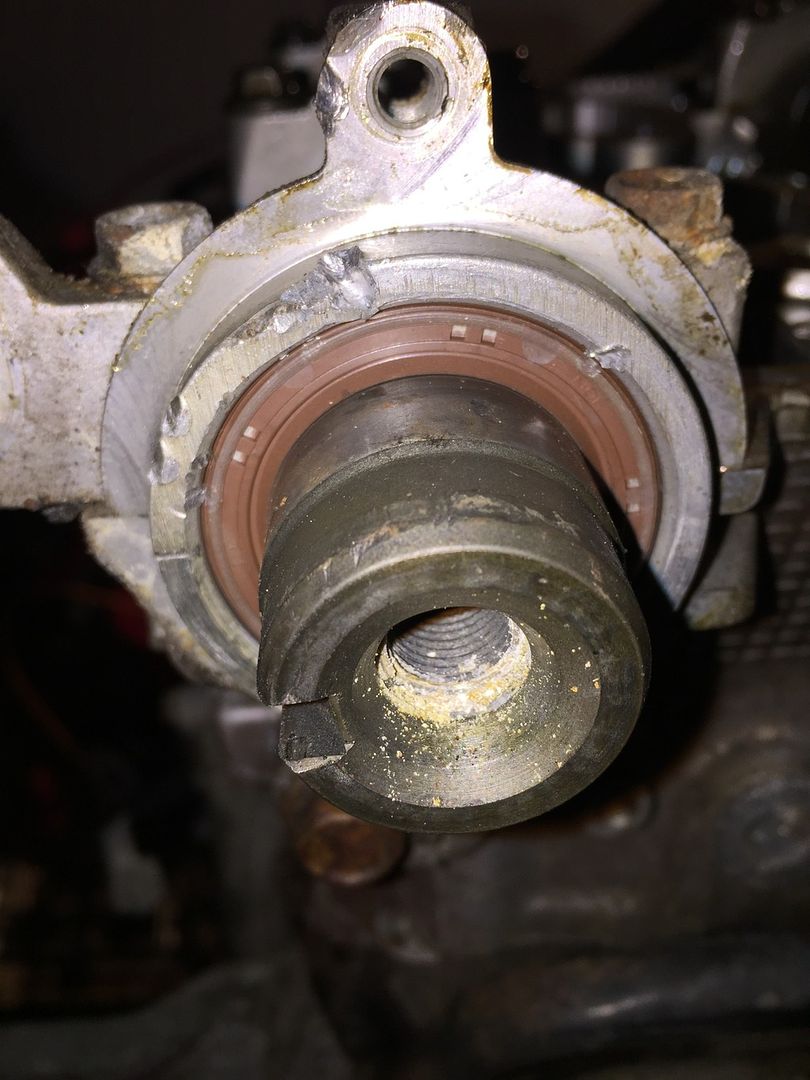

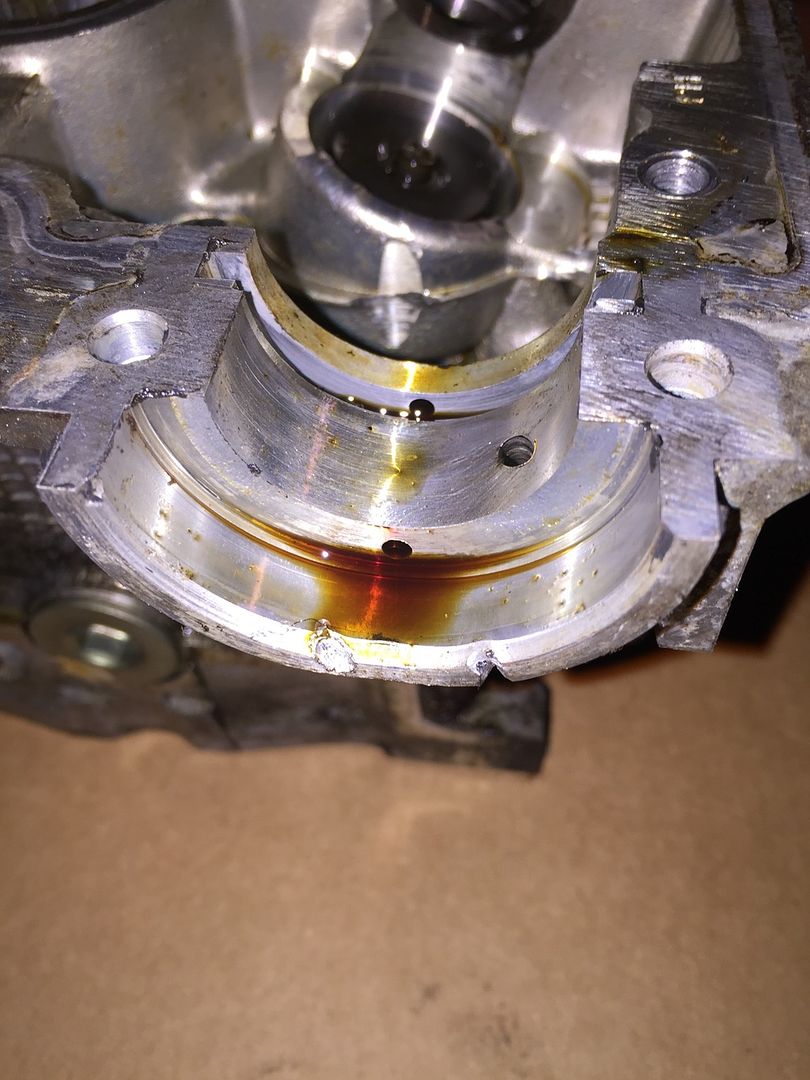

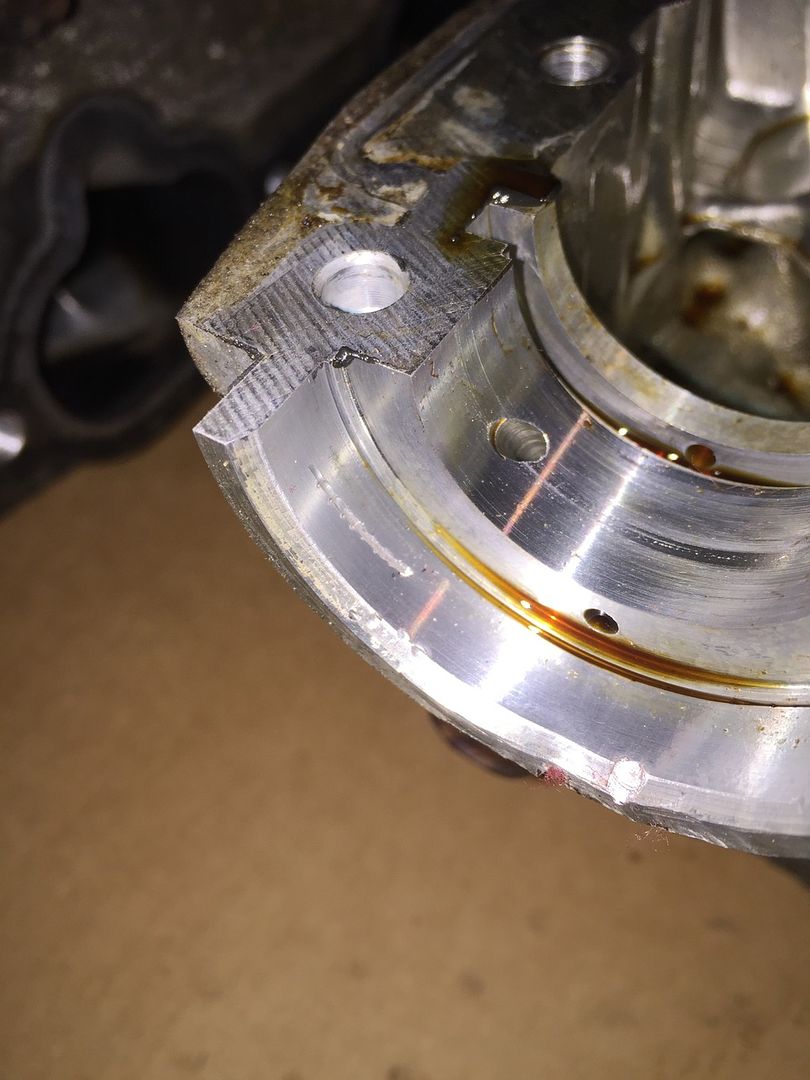

Got the heads off and discovered whoever worked on the car last really dinged up the area where the cam seals sit. Its a shame because the rest of the heads are pristine.

So, to all of you machinists, are these fixable? Can they measure the seal area with the cam cap installed and just sand or machine the raised areas that protrude into the seal area out. It seems to me its possible as the seal just sits in there. or should I not worry about it ans just install new seals? the old ones weren't leaking at all.

Got the heads off and discovered whoever worked on the car last really dinged up the area where the cam seals sit. Its a shame because the rest of the heads are pristine.

So, to all of you machinists, are these fixable? Can they measure the seal area with the cam cap installed and just sand or machine the raised areas that protrude into the seal area out. It seems to me its possible as the seal just sits in there. or should I not worry about it ans just install new seals? the old ones weren't leaking at all.