Thank you Zend, molakule and supercity

Originally Posted By: zeng

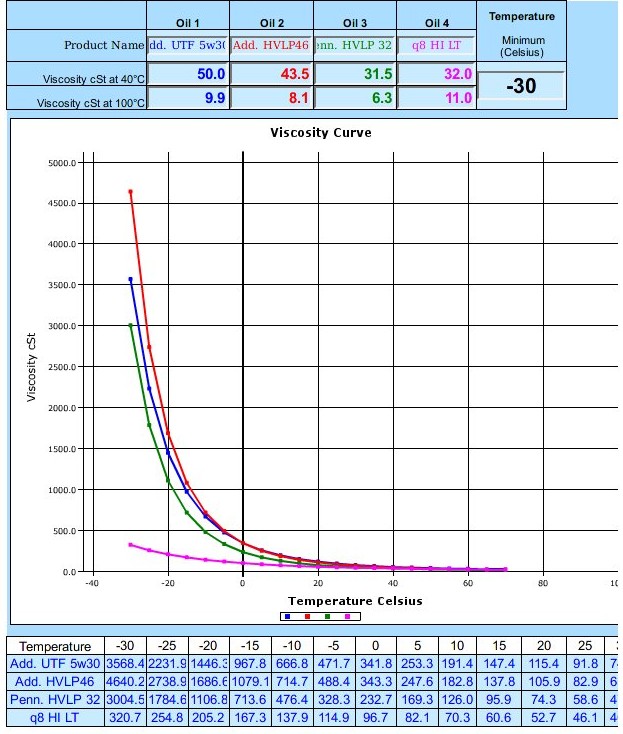

I would assume the spec'ed 20~40 mm²/s as

optimum operating viscosity, and hazard a guess of its

minimum allowable viscosity as 13~16 mm²/s.

The Q8's operating viscosity would drop to 20 mm²/s at about 60*C, above which you may loose gear pump longevity protection.

Considering the upper side over 60°C, the values for both a Q8 Artctic, HVLP46 or 5w30 UTTO are quite the same, around 20 cst. So there will be no change choosing any of them.

The only difference is on the down size, and only the Q8 performs well here.

I have really no idea of the oil temperature that will be reached in summer during work, so I don't know if there will be a problem here...

Anyway, I have a spare pump, only 80$ in China...

Quote:

I would feel the Q8 is not suitable for the powershift transmission.

Here is the plan:

- Engine: Addinol Commercial E7 5w40 CI-4/SL which can go in all my cars, truck and tractors, so universal.

ACEA E7 / E5 / E3

API CI-4 Plus / CI-4 / CH-4 / CG-4 / CF-4 / SL / SJ

MAN M 3275-1

MB-Freigabe 228.3

Volvo VDS-3

Renault RLD / RLD2

MTU Ölkategorie 2

MACK EO-N / EO-M Plus

Cummins CES 20077 / 76

Caterpillar ECF-2 / ECF-1-a

Deutz DQC III-10

Vis 100°C mm²/s 13,8 ASTM D 704

VI 174 DIN ISO 2909

Pumpfähigkeit °C bis -35 ASTM D 4684

Flammpunkt COC °C min. 225 DIN EN 2592

Pourpoint °C max. -43 ASTM D 7346

TBN mg KOH / g 9,4 DIN ISO 3771

- Powershift: Addinol UTTO Plus 5w30 (which is also the same for my tractors)

John Deere JDM J 20D (inkl. LD303, J14B/C, J20A-C)

Steyr BR 80 Getriebe / Transaxle / Hydraulik

Massey Ferguson M-1110 / 1127 / 1129 / 1141 / 1143 / 1145

Volvo WB 101

TCM Stapler

Allison C4 (C2, C3)

Caterpillar TO-2

Renk-Doromant

Kubota Super UDT

Komatsu

DIN 51524-2 (HLPD, HM)

DIN 51524-3 (HVLPD, HV)

Denison HF-2, HF-1, HF-0 (außer Demulgiervermögen)

API GL-4

Vis 40 °C mm²/s 50 ASTM D 7042

Vis 100 °C mm²/s 9,9

Viskositätsindex 183 DIN ISO 2909

Flammpunkt COC °C min. 230 DIN EN ISO 2592

Pourpoint °C max. -47 ASTM D 7346

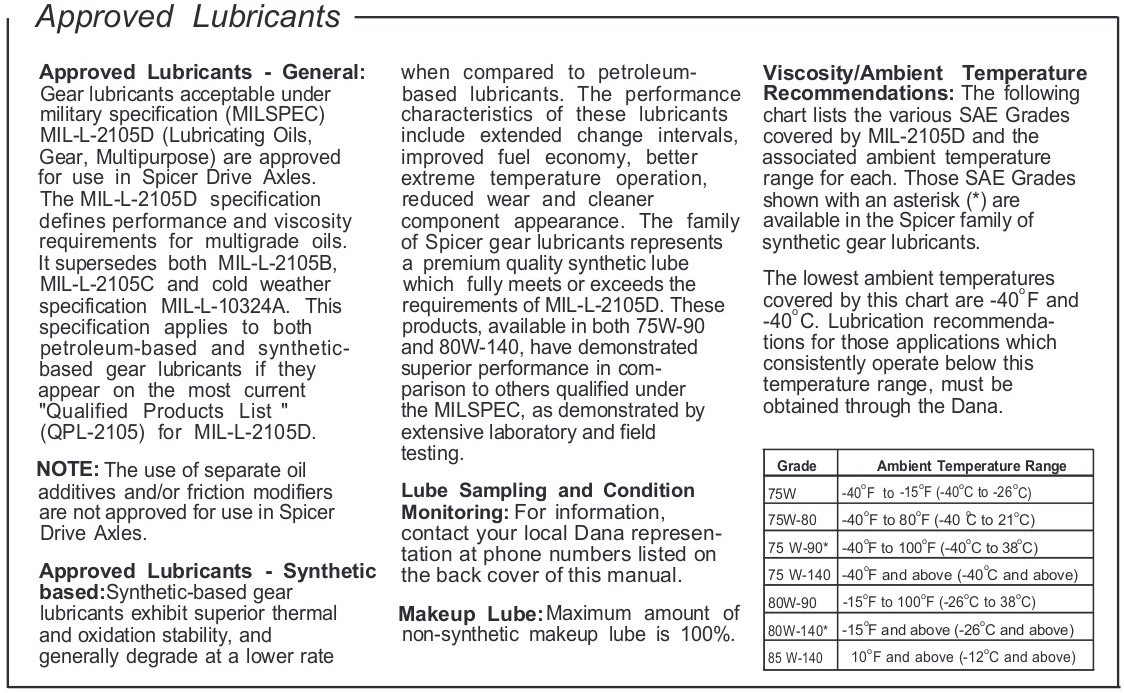

- Axles: Addinol GH 75w90 GL5 (which is also the same for my tractors)

API GL-4 / GL-5

MIL-L-2105 D

VW 501 50 (G 50)

ZF TE-ML 07A, 08

Vis 100°C / mm²/s / 15,0 / ASTM D 7042

Viskositätsindex / / 178 / DIN ISO 2909

Scheinbare Viskosität bei -40°C / mPa*s / 150.000 / DIN 51398

Flammpunkt COC / °C / 215 / DIN EN 2592

Pourpoint / °C / -45 / ASTM D7346

- Hydraulic: Q8 Hindemith LT (which can go also in my tractors hydraulics)

http://www.q8oils.co.uk/downloads_temp/e3327415-5851-48f2-9b03-cc427cd60d4b.PDF

What do you think about it ?