Originally Posted By: ChevyBadger

Originally Posted By: Brybo86

And I'll say it again.... Pics please

click on the ebay link, I will try to remember to get pics of it fomorrow.

There is only 1 pic and it's black and white. Taken circa 1982 with Kodak film then scanned with a $40 All in one printer scanner fax machine.

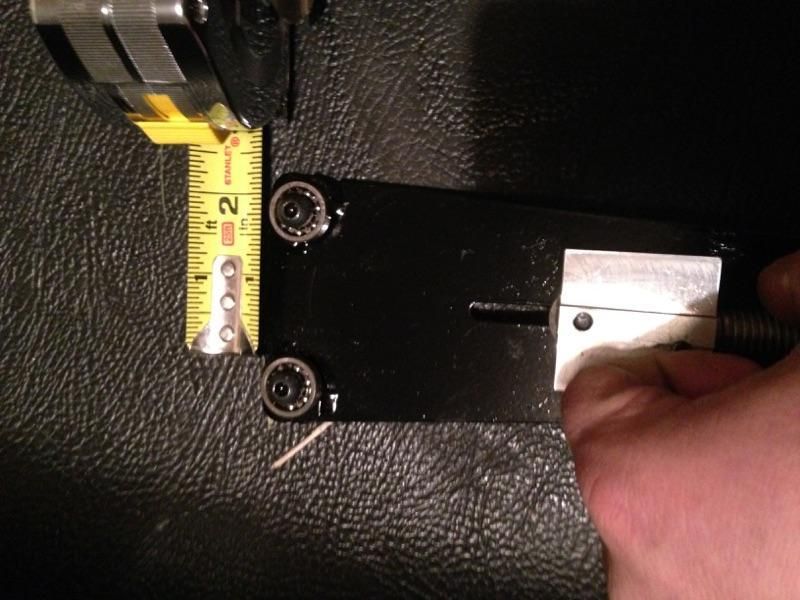

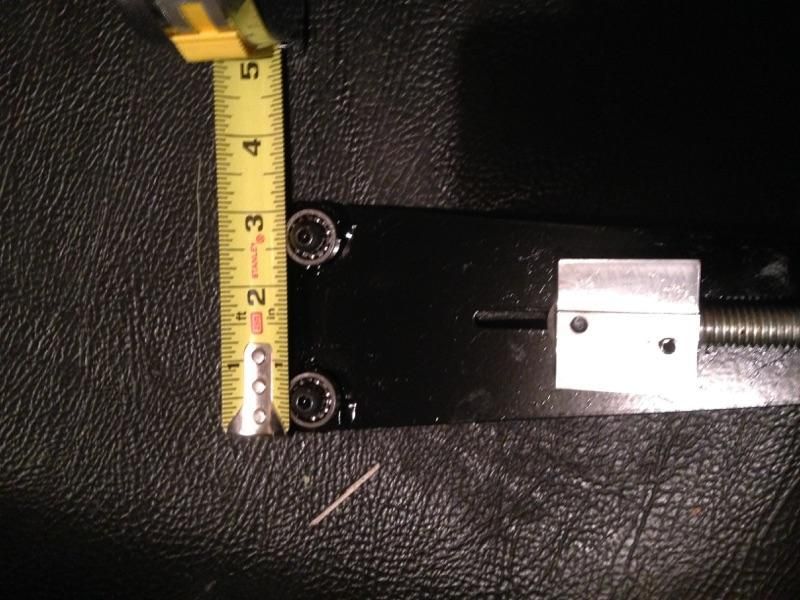

Distance between idler wheels would be nice as well.

Originally Posted By: Brybo86

And I'll say it again.... Pics please

click on the ebay link, I will try to remember to get pics of it fomorrow.

There is only 1 pic and it's black and white. Taken circa 1982 with Kodak film then scanned with a $40 All in one printer scanner fax machine.

Distance between idler wheels would be nice as well.

Last edited: