Allow me to start with yes, I have read Mr. Daniel Sterns material. He does not discuss fuse SIZE.

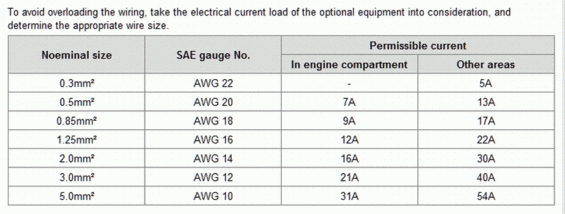

I am working on a relay setup for my 1996 Mustang. Planning on running two seperate relays, one for the low beams and one for the highbeams (so one must handle 110 watts total and one 130 watts). Now I've seen some various talk on the net and based on the below I'm not sure what the more appropriate fuse size is. I am currently planning on running 14awg power wires from the ear relay to each bulb with 12awg power wires to each relay and for both bulb grounds (each bulb has its own ground which is shared by both filaments).

According to this: http://www.oznium.com/forum/topic15761

My max current is 11.8A since my smallest wire is 14awg. Now I figure that my current draw will be inversely proportional to voltage, which should range from 12.8vdc to 14.8vdc giving a maximum current draw on the highbeam side of 10.2A and a minimum current draw on the low beams of 7.4A. Now it looks like the factory fusing is a 20A common for pretty much all the exterior lights. Now, my load is more concentrated but since the wiring will be significantly stouter than OEM would a 20A fuse still be appropriate or should I keep it down to a 15A or less?

I am working on a relay setup for my 1996 Mustang. Planning on running two seperate relays, one for the low beams and one for the highbeams (so one must handle 110 watts total and one 130 watts). Now I've seen some various talk on the net and based on the below I'm not sure what the more appropriate fuse size is. I am currently planning on running 14awg power wires from the ear relay to each bulb with 12awg power wires to each relay and for both bulb grounds (each bulb has its own ground which is shared by both filaments).

According to this: http://www.oznium.com/forum/topic15761

My max current is 11.8A since my smallest wire is 14awg. Now I figure that my current draw will be inversely proportional to voltage, which should range from 12.8vdc to 14.8vdc giving a maximum current draw on the highbeam side of 10.2A and a minimum current draw on the low beams of 7.4A. Now it looks like the factory fusing is a 20A common for pretty much all the exterior lights. Now, my load is more concentrated but since the wiring will be significantly stouter than OEM would a 20A fuse still be appropriate or should I keep it down to a 15A or less?