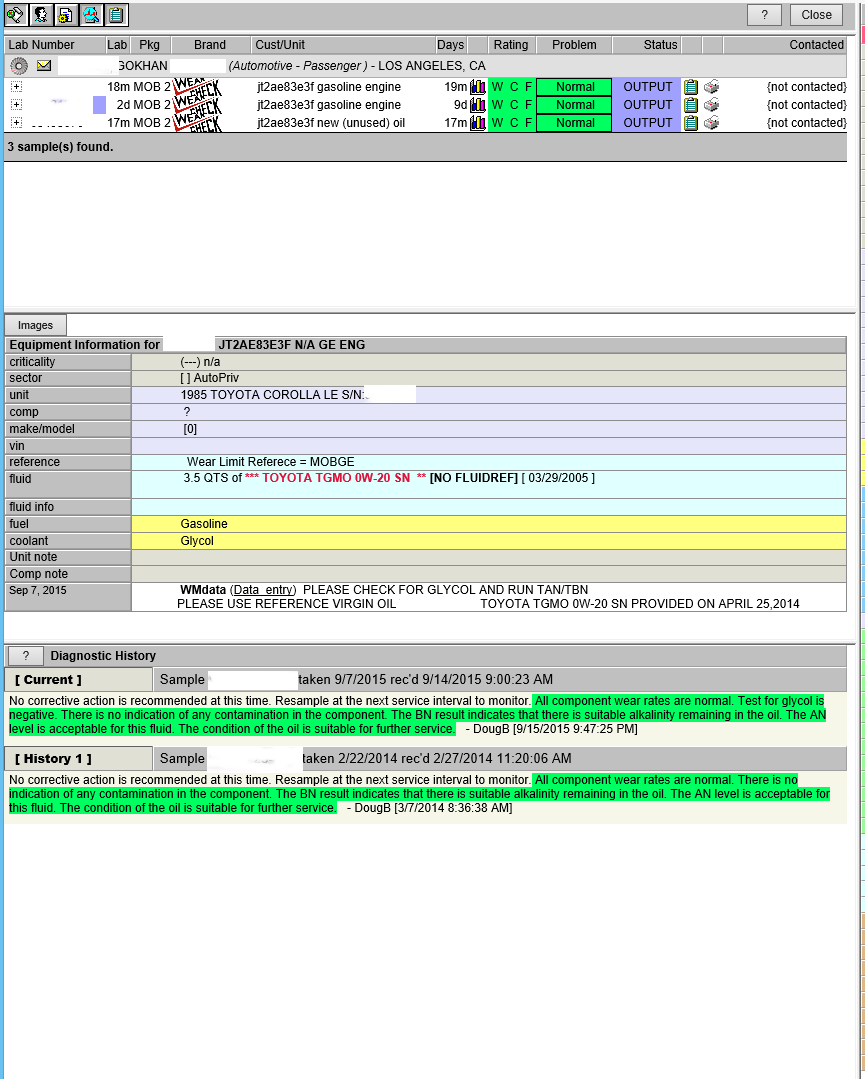

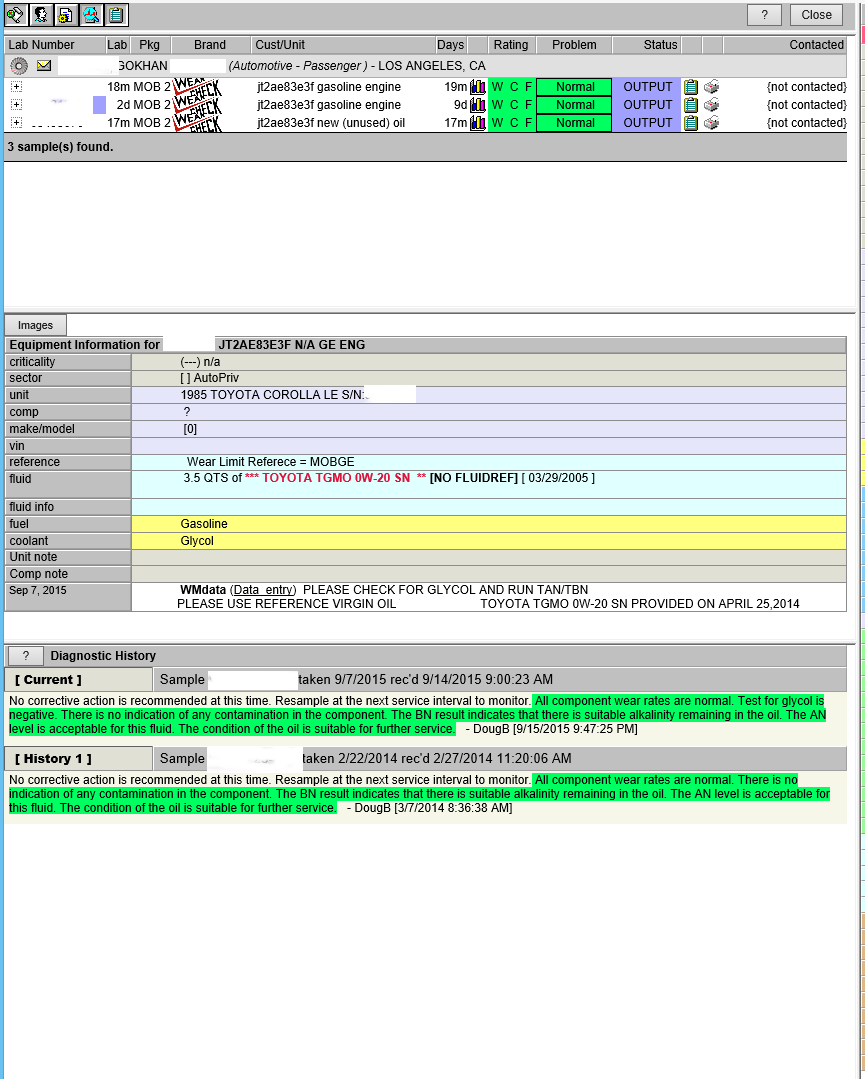

This is my third UOA with Toyota (TGMO) 0W-20 SN/GF-5 made in US by ExxonMobil.

The OCI duration is 5286 miles, 506 days. No makeup oil was added and the oil consumption was minimal -- about 0.3 - 0.4 quarts over the OCI (similar to last OCI) and probably mostly due to a small leak at the oil pan. Almost no oil consumption is thanks to replacing my valve-stem oil seals. Oil-change capacity is 3.5 quarts with oil-filter change. Dry-fill capacity is 3.9 quarts. The filter used is Toyota 90915-YZZF2. Cumulative miles and age on the 1.6-liter carbureted SOHC engine at the time of the UOA sample is 260480 miles, ~ 30 years. In addition to some high-speed freeway driving, the car mostly saw a lot of short trips that you would think would be hard on the oil. Temperatures in the area were mild, warm, or hot during last year.

I used the $30 (shipping included) high-quality aluminum Blackstone vacuum pump for oil sampling and it worked wonderfully. It's clean, fast, accurate, and lets you have a UOA oil before you change the oil so that you can use a different oil next time if you aren't satisfied. I strongly recommend it to everyone over the messy drain-hole method -- it's much, much, much better. Note that the pump doesn't touch the oil and doesn't require cleaning.

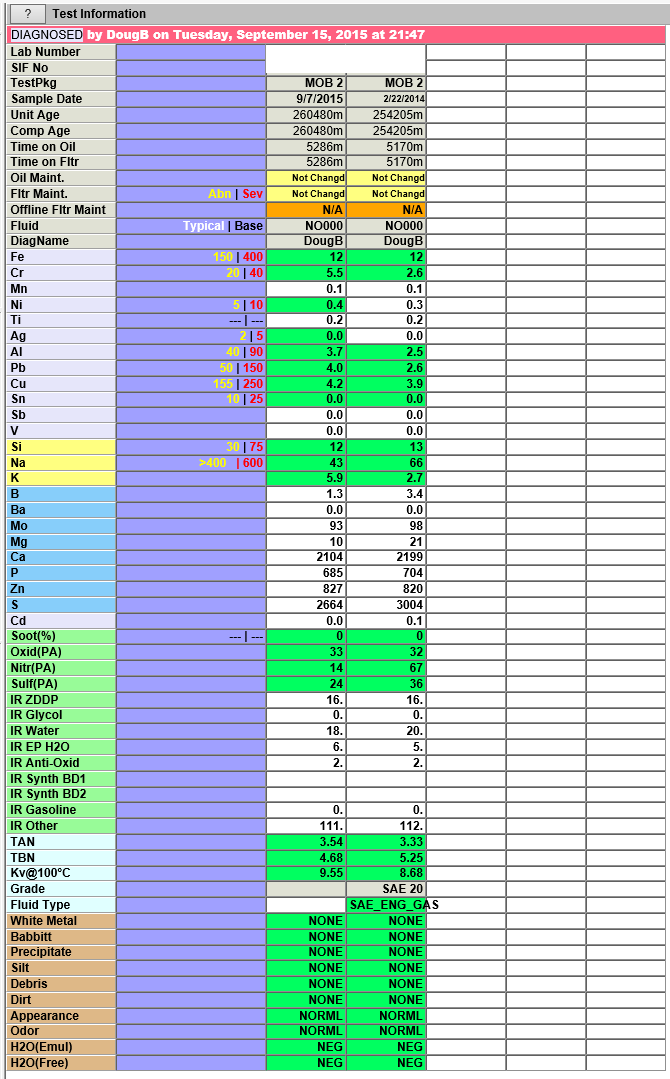

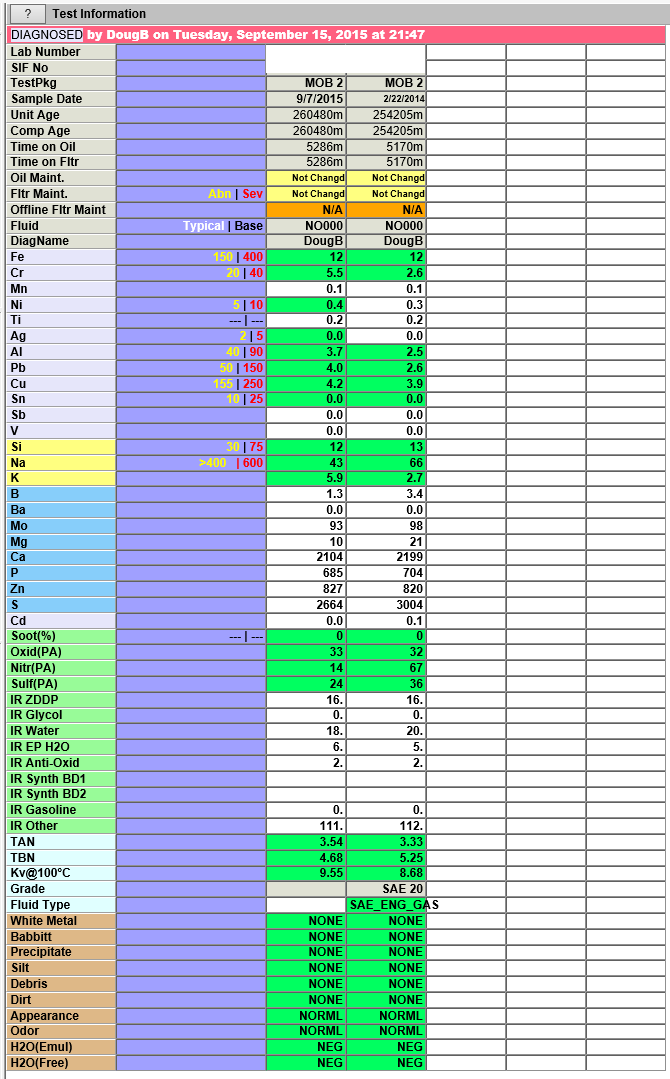

Note that the TBN and TAN are 4.68 and 3.54. My rule of thumb is that the TBN needs to stay larger than the TAN over the OCI for optimal protection. Note that the TBN value by WearCheck is the true TBN using the modern test method. Blackstone TBN values are underestimated.

Silicon is very impressive: 12 ppm vs. the 11 ppm of the virgin oil -- almost no dust is entering the engine, thanks to my meticulous seating of the air-filter gaskets over the carburetor.

Note that the viscosity at 9.55 cSt is very high for a 0W-20. I am guessing this to be due to some antifreeze contamination. There is 43 ppm sodium (Na) in the UOA signaling antifreeze contamination. However, they didn't find any glycol in the IR test. Go figure.

These are my previous UOAs, TGMO 0W-20 SN @ 249035 miles and PYB 5W-20 SN @ 243729 miles:

Previous Blackstone UOAs

Here is the official VOA of TGMO 0W-20 SN virgin oil

I am going to use ACDelco cooling-system seal tabs (part no. 10-108), hoping that it will stop my coolant seep. It seems to be happening through some holes in the aluminum cylinder head.

Note that this time the driving conditions were worse with a lot of short trips. Also, I broke the 1-year-maximum-OCI rule (!!) and waited for 506 days before I sampled for the UOA since my mileage was still low. These probably contributed to worse wear-metal results on the lead, aluminum, and chromium this time. I think I will give the thick oil a try next time (in my oil change this or next weekend) and run Mobil 1 0W-40 SN. What do you guys think?

The OCI duration is 5286 miles, 506 days. No makeup oil was added and the oil consumption was minimal -- about 0.3 - 0.4 quarts over the OCI (similar to last OCI) and probably mostly due to a small leak at the oil pan. Almost no oil consumption is thanks to replacing my valve-stem oil seals. Oil-change capacity is 3.5 quarts with oil-filter change. Dry-fill capacity is 3.9 quarts. The filter used is Toyota 90915-YZZF2. Cumulative miles and age on the 1.6-liter carbureted SOHC engine at the time of the UOA sample is 260480 miles, ~ 30 years. In addition to some high-speed freeway driving, the car mostly saw a lot of short trips that you would think would be hard on the oil. Temperatures in the area were mild, warm, or hot during last year.

I used the $30 (shipping included) high-quality aluminum Blackstone vacuum pump for oil sampling and it worked wonderfully. It's clean, fast, accurate, and lets you have a UOA oil before you change the oil so that you can use a different oil next time if you aren't satisfied. I strongly recommend it to everyone over the messy drain-hole method -- it's much, much, much better. Note that the pump doesn't touch the oil and doesn't require cleaning.

Note that the TBN and TAN are 4.68 and 3.54. My rule of thumb is that the TBN needs to stay larger than the TAN over the OCI for optimal protection. Note that the TBN value by WearCheck is the true TBN using the modern test method. Blackstone TBN values are underestimated.

Silicon is very impressive: 12 ppm vs. the 11 ppm of the virgin oil -- almost no dust is entering the engine, thanks to my meticulous seating of the air-filter gaskets over the carburetor.

Note that the viscosity at 9.55 cSt is very high for a 0W-20. I am guessing this to be due to some antifreeze contamination. There is 43 ppm sodium (Na) in the UOA signaling antifreeze contamination. However, they didn't find any glycol in the IR test. Go figure.

These are my previous UOAs, TGMO 0W-20 SN @ 249035 miles and PYB 5W-20 SN @ 243729 miles:

Previous Blackstone UOAs

Here is the official VOA of TGMO 0W-20 SN virgin oil

I am going to use ACDelco cooling-system seal tabs (part no. 10-108), hoping that it will stop my coolant seep. It seems to be happening through some holes in the aluminum cylinder head.

Note that this time the driving conditions were worse with a lot of short trips. Also, I broke the 1-year-maximum-OCI rule (!!) and waited for 506 days before I sampled for the UOA since my mileage was still low. These probably contributed to worse wear-metal results on the lead, aluminum, and chromium this time. I think I will give the thick oil a try next time (in my oil change this or next weekend) and run Mobil 1 0W-40 SN. What do you guys think?