Hi all,

For their loaders hydraulics, caterpillar ask for a TO-4 oil with a least 900ppm of Zinc.

But these oils are multifunctionnal hydraulic/transmission so I'd like to know if the 900ppm is needed for the hydraulic use or only for the transmission part...

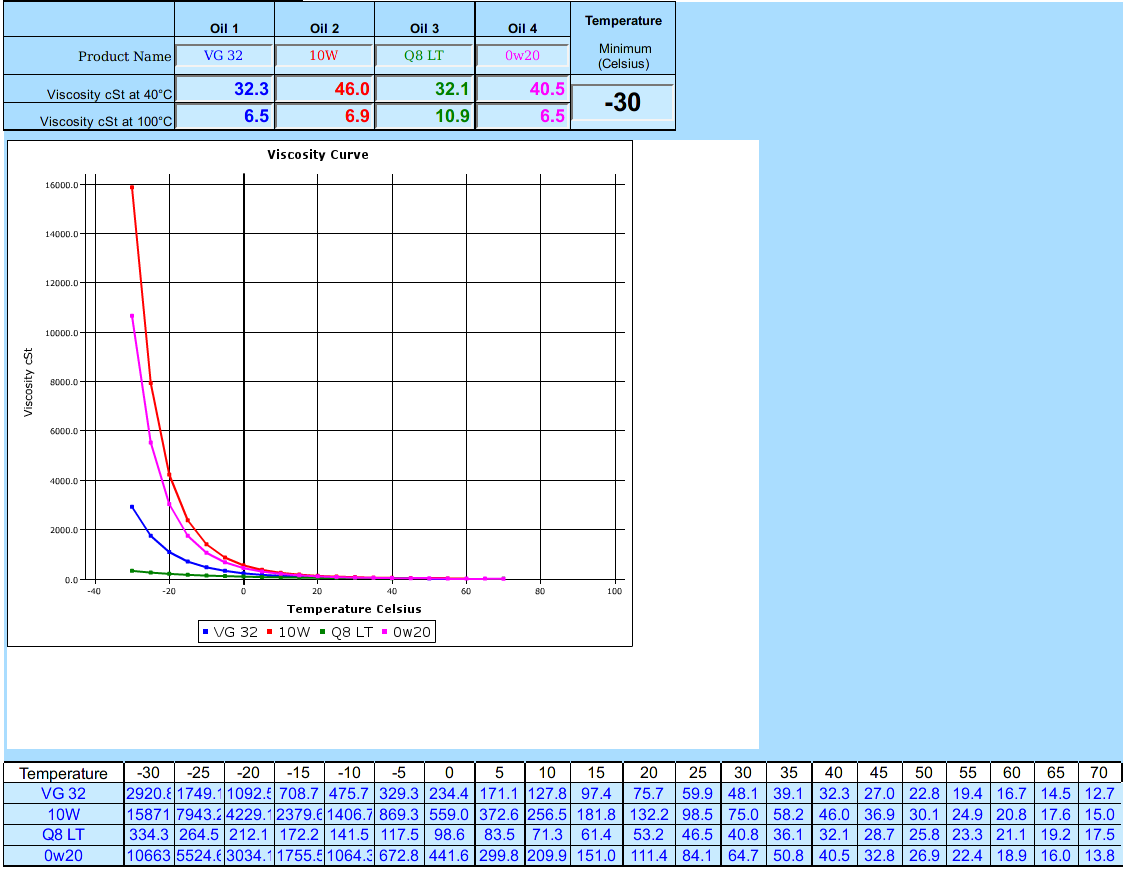

I need to use a loader with a gear hydraulic pump from -30°C to + 30°C (-22°F to 86°F), so if I want a TO-4, I need the artic version which cost a LOT...

So, can I chose a simple VG 22 or VG 32, detergent or not, without problem for only the hydraulic knowing that they have a low Zinc ppm, or do I still need a high Zinc in the hydraulic oil ?

Thanks !

For their loaders hydraulics, caterpillar ask for a TO-4 oil with a least 900ppm of Zinc.

But these oils are multifunctionnal hydraulic/transmission so I'd like to know if the 900ppm is needed for the hydraulic use or only for the transmission part...

I need to use a loader with a gear hydraulic pump from -30°C to + 30°C (-22°F to 86°F), so if I want a TO-4, I need the artic version which cost a LOT...

So, can I chose a simple VG 22 or VG 32, detergent or not, without problem for only the hydraulic knowing that they have a low Zinc ppm, or do I still need a high Zinc in the hydraulic oil ?

Thanks !

Last edited: