Originally Posted By: JHZR2

Ok well I had done all the coatings, sanding, and then let it cure weeks... Now to smooth it. As the coating fully cured and shrunk, I could see that some of the scratches from the 320 paper left a few marks that the subsequent coatings shrunk in to.

My aim is to do 800, 1000,1500, 2000 grit with soapy water, then 4f pumice and then rotten stone.

This was before. There were dust nibs in the finish, not many, but certainly some and some artifacts from earlier ones.

It worked well with some slightly soapy water and the 800 grit.

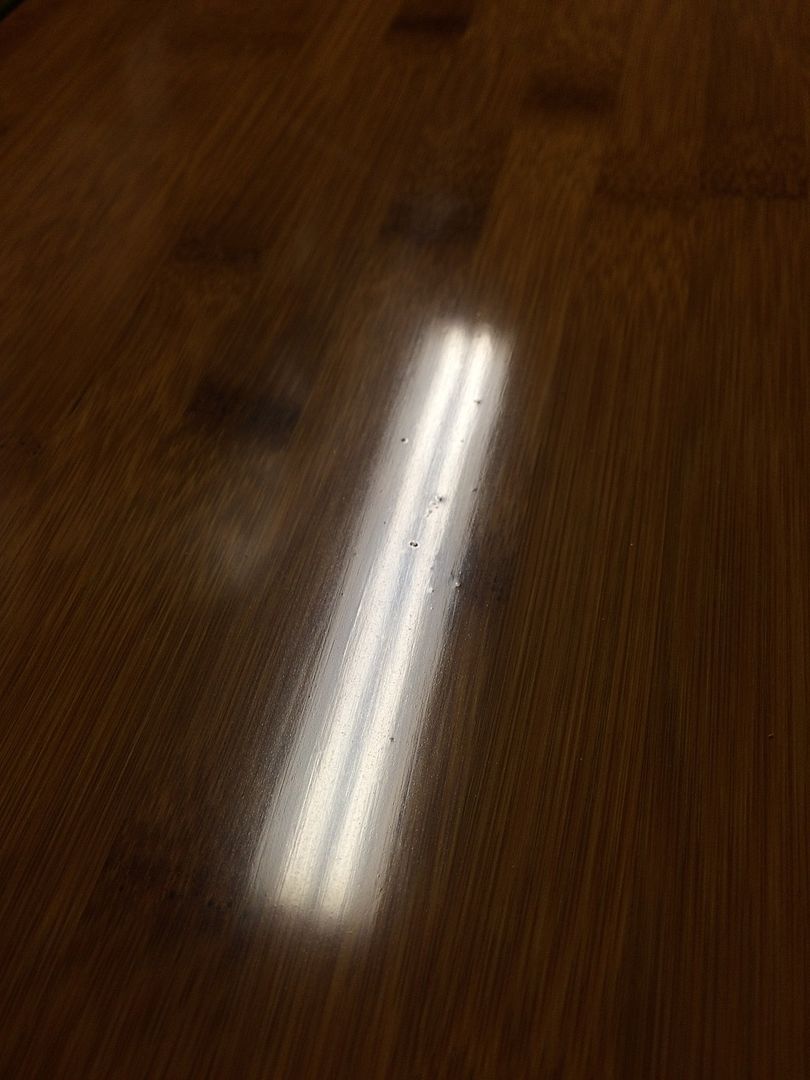

Thing was stuff like this:

What gives? There were no nibs after this, but what's with these artifacts and the smooth area around them?

I figured that Id get them all with the 1000 grit, so here's the table dry and ready:

So I sanded with 1000, wet. Nothing really to show yet.

With the paper, I'll sand with the grain, long strokes only. But once I get to my compounds, I figure I'll do circles with my felt blocks. Or should I go with the grain?

I may try using my RO after the rotten stone with a car polish and maybe even a wax. What do you think?

My two cents:

1. You're getting ahead of yourself. You flatten & level with 400 or 320, not 1000. The block helps spread the pressure so you don't cut through the finish. Think about it: If your block is 5 x 7, that's 35sqr. in. Compare that to sanding by hand, with your finger tips: Far less sqr. in. + much easier to cut through due to increased pressure/sqr. in.

2. Those shiny areas you see are low, below the areas that are dull. So you'll have to sand with a lower grit until they too are dull. To do that with 1000 or even 800 will take until Independence Day. Further, this is why your paper clogs, even wet sanding. Again, I'd suggest reading a book by one of the pros mentioned earlier. They'd never recommend leveling a finish with 1000.

3. You do have to be careful when using soapy water. Why? Because if you do cut through the finish, you'll wet the wood, which will swell. You'll also have water trapped below the finish, which isn't good. I prefer to use mineral spirits, which won't cause this.

4. Your willingness to learn this is admirable. As you've discovered, it's not easy. I'm not sure just how "flat" the bamboo surface was before you began. Remember flatness when finishing is measured in the thickness of the finish when cured. Filling in an unlevel ripple in the wood that's say, 1/16" of an inch with a film that cures to maybe 1/100 of an inch will take a many, many layers.

The telescope I restored is made of BB ply, which is quite flat as long as there are no divots in the veneer. Not sure if your bamboo table was as flat to start with. My point is it makes a HUGE difference with the flatness of the wood itself, even before any finish is applied. A ROS is good at many things, but it won't flatten wood or any finish. That's why you use a sanding block.

5. As an experiment, you might try using a smaller, palm sized sanding block made of something very hard & flat. No sponge rubber or foam as a backing. I made mine out of two layers of 3/4" BB ply glued together with a 1/8" hard rubber sheet glued to the bottom. This prevents the paper from slipping and ripping ar the 90° edge. With 400g, go after a small area like the one shown with low spots and see how long it takes to get it evenly dull. If it going too slow, then do the same with 320g. Work an area about 12" x 12" at a time. If soapy water works for you, then use it. But sand it wet. Once it's even, stop and do another 12x12 section.

Once the entire surface is evenly dull, THEN AND ONLY THEN, do you go up through the grits, using less pressure. Good luck!