Someone posted something similar previously and it got me to thinking about my own situation. It's been on my mind for a few years, but other more immediate things have pushed it back.

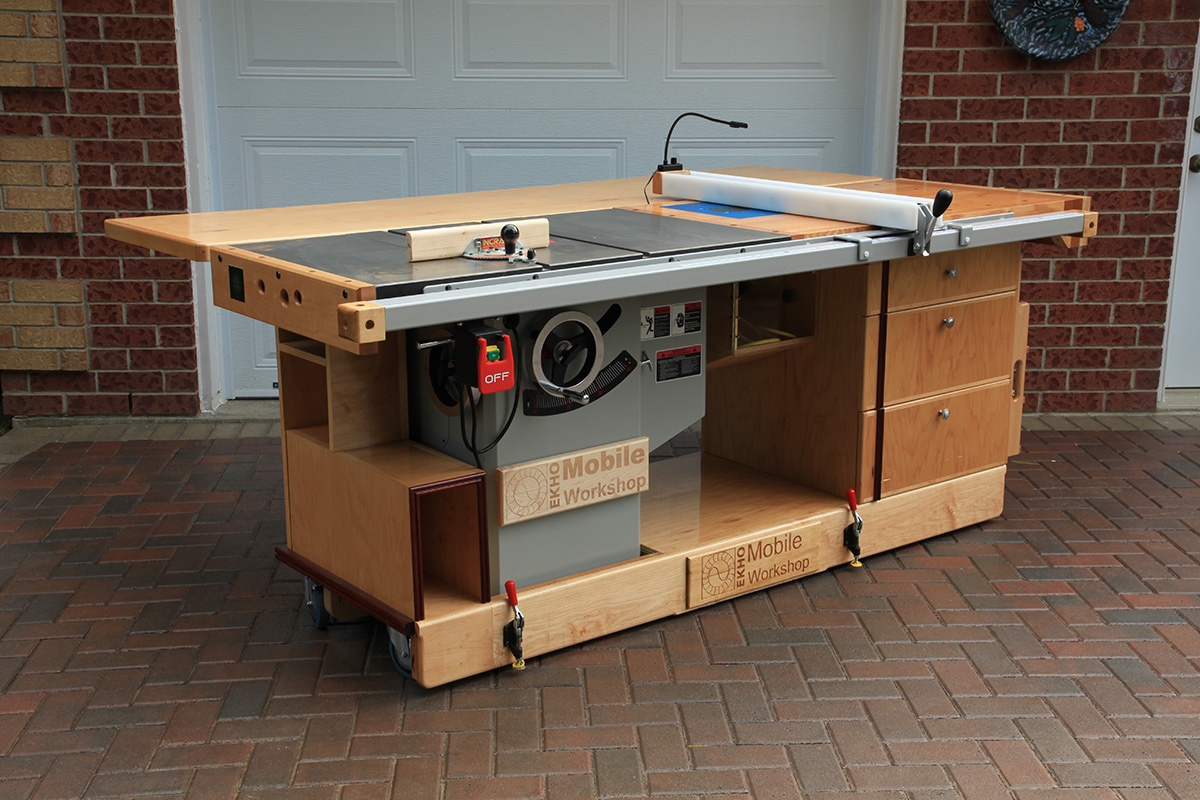

The other day I pulled it out, hearing for the umpteenth time one leg dragging on the uneven concrete floor, making a very loud screech. I've always wanted to integrate a router table into one of the extension tables and both are in bad needs of new tops. Another issue is the current version has poorly thought out storage. I built a plan from ShopNotes and it was certainly an improvement over the stationary metal stand that came with the saw. The pivot mechanism that enables you to raise it onto wheels doesn't keep the force in a vertical line, which won't work well over time, heat & humidity.

Another issue is the long wings are not supported at their ends, only along the front/back with the iron angle from the Biessemier fence I purchased 22yrs ago. The entire top needs to be in the same horizontal plane for accuracy and that's tough to do without supports.

I already know what the wings will be surfaced with to replace the Formica: White Corian. It's dead flat, easily machineable, I can write on it, the white color makes things easily noticed. When it becomes scratched up, it's easy to polish out. I can also get it at no cost. Having a built-in router set-up saves space which is at a premium in my garage. Most things are on wheels as the sled stays in the garage.

Bill Hylton has some great ideas in Router Magic. I built a set of concentric rings for a portable top and they came out very well. Another idea I'll use is no drop-in router plate. They catch dust, the clear ones sag causing joint alignment issues. I've made more than a few attempting to get one that's flat. I was considering milled aluminum plate as well. I'm currently using BB ply glued to MDF, with both sides covered in Formica to keep it flat. That's worked the best.

Another reason to ignite this project is to build some nice garage cabinets with a work surface below and big sliding drawers underneath so I don't have to get on my hands & knees! Plus it keeps the dust & spiders out. I watched a Norm Abram show where he built new fixtures for the NYW and he went with all drawers on 100# slides. Very nice indeed!

The true endangered species in my set-up is clear horizontal space and storage. Having it well organized would go a long way towards working efficiently. This cabinet construction would also be a prelude to building new cabinets in the kitchen.

I'm open to ideas, comments, suggestions from others who have done this. I've been collecting magazine articles for years on this. Time to move forward.

The other day I pulled it out, hearing for the umpteenth time one leg dragging on the uneven concrete floor, making a very loud screech. I've always wanted to integrate a router table into one of the extension tables and both are in bad needs of new tops. Another issue is the current version has poorly thought out storage. I built a plan from ShopNotes and it was certainly an improvement over the stationary metal stand that came with the saw. The pivot mechanism that enables you to raise it onto wheels doesn't keep the force in a vertical line, which won't work well over time, heat & humidity.

Another issue is the long wings are not supported at their ends, only along the front/back with the iron angle from the Biessemier fence I purchased 22yrs ago. The entire top needs to be in the same horizontal plane for accuracy and that's tough to do without supports.

I already know what the wings will be surfaced with to replace the Formica: White Corian. It's dead flat, easily machineable, I can write on it, the white color makes things easily noticed. When it becomes scratched up, it's easy to polish out. I can also get it at no cost. Having a built-in router set-up saves space which is at a premium in my garage. Most things are on wheels as the sled stays in the garage.

Bill Hylton has some great ideas in Router Magic. I built a set of concentric rings for a portable top and they came out very well. Another idea I'll use is no drop-in router plate. They catch dust, the clear ones sag causing joint alignment issues. I've made more than a few attempting to get one that's flat. I was considering milled aluminum plate as well. I'm currently using BB ply glued to MDF, with both sides covered in Formica to keep it flat. That's worked the best.

Another reason to ignite this project is to build some nice garage cabinets with a work surface below and big sliding drawers underneath so I don't have to get on my hands & knees! Plus it keeps the dust & spiders out. I watched a Norm Abram show where he built new fixtures for the NYW and he went with all drawers on 100# slides. Very nice indeed!

The true endangered species in my set-up is clear horizontal space and storage. Having it well organized would go a long way towards working efficiently. This cabinet construction would also be a prelude to building new cabinets in the kitchen.

I'm open to ideas, comments, suggestions from others who have done this. I've been collecting magazine articles for years on this. Time to move forward.