This one had been collecting dust for far too many years. I recently decided to resurrect it along with the loudspeaker shown in the Photo forum.

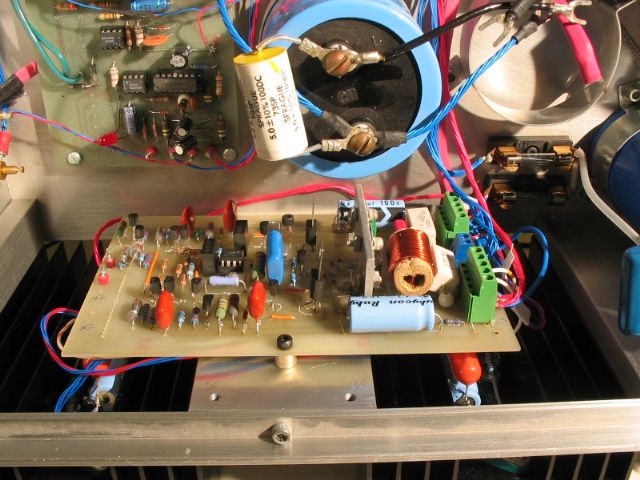

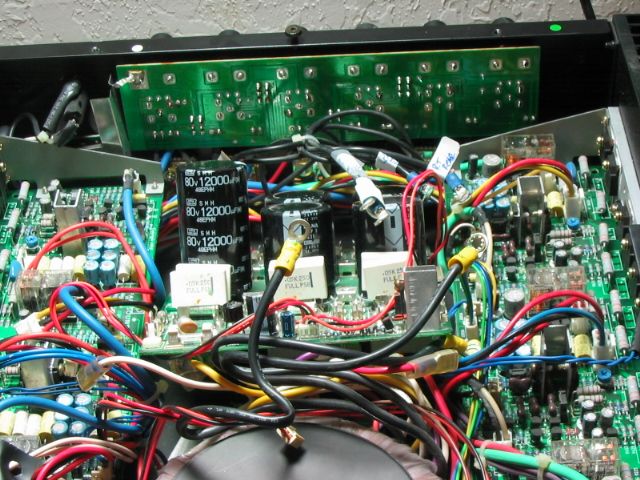

I built this from scratch about 22 years ago, including the aluminum chassis. My first audio metalworking project. Quite a learning experience. Drilled and tapped LOTS of holes...mostly in the correct place.

This amp quit working several years ago and I quickly substituted a DH220 in its place. Then recently, the DH220 quit! So I've been without the four 12" drivers that make up the bass section of my reproduction system!

I slowly powered it up using a VARIAC, one channel at a time, fed it a 1kHz sine wave and observed the output on the oscilloscope. IT looked fine. So I ran some power tests and noted that the voltage rail regulators were sagging about 5V when the amp was delivering 90W to an 8 Ohm load. They shouldn't sag at all.

So I bypassed them and redid the power testing. This time I measured 140W RMS into 8 Ohm at clipping, per channel but not both channels driven simultaneously as I only have one load.

I removed and began troubleshooting the regulators and discovered the main fault lay in the wrong zener choices and not enough voltage overhead to keep them in regulation under load. Another issue to account for is my outlet Voltage tends around 125VAC instead of 117VAC. As such, the 500VA torroid used buzzes. You may recall a similar issue with the HK Citation 7 I resurrected earlier in this forum. It was clearly not designed to run at an elevated outlet voltage and as such, had cooked itself to death: Overheating regulators, heatsinks too hot to touch, toasting the main ckt board, peeling board traces, etc. It's now only turned on with the master switch when needed.

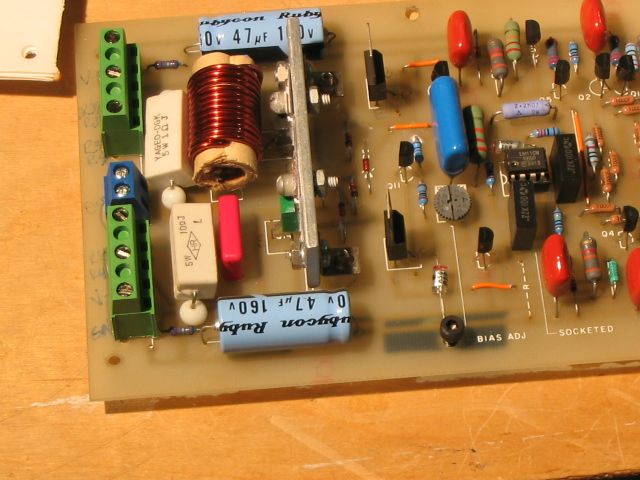

Back to the amp at hand....the regulators are now working properly and no-load to full-load Voltage drop is now within 0.1VDC! Quite an improvement in regulation!

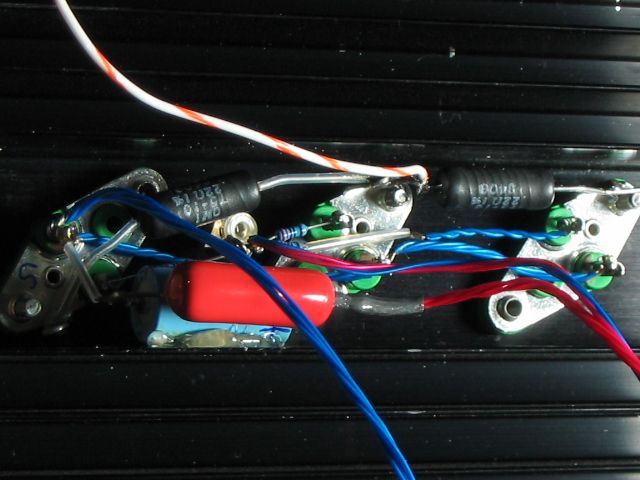

I currently have the MOSFET heatsinks out to install some 0.22 Ohm source resistors. These ensure equal current sharing and provide some source degeneration and local feedback to stabilize the output devices.

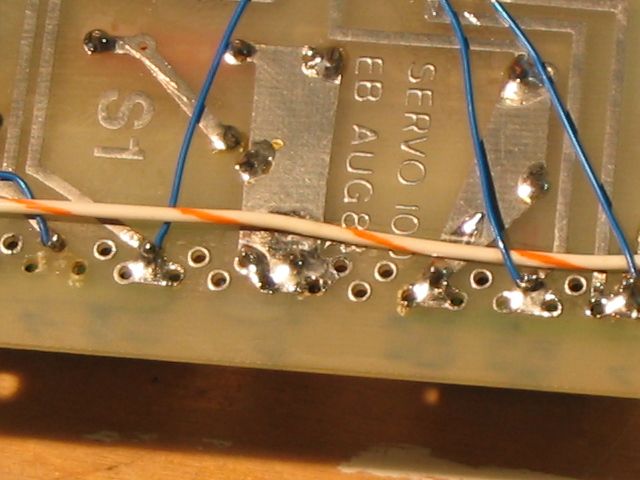

I've also removed the driver boards to update the I/O connections from wires directly soldered to the boards to using terminal blocks instead. This greatly enhances board removal and prevents PCB foil damage from repeated in & out.

I'll post photos later. It'll be great having this custom amp back in service. Then I can put the DH220 on the bench. I also have a Parasound 5 ch amp that has begun to hum through the loudspeakers. I suspect the electrolytic caps have aged, the capacitance has fallen and thus noise is getting though the power supply. It may be time for a 're-cap'...litterally.

Stay Tuned!

I built this from scratch about 22 years ago, including the aluminum chassis. My first audio metalworking project. Quite a learning experience. Drilled and tapped LOTS of holes...mostly in the correct place.

This amp quit working several years ago and I quickly substituted a DH220 in its place. Then recently, the DH220 quit! So I've been without the four 12" drivers that make up the bass section of my reproduction system!

I slowly powered it up using a VARIAC, one channel at a time, fed it a 1kHz sine wave and observed the output on the oscilloscope. IT looked fine. So I ran some power tests and noted that the voltage rail regulators were sagging about 5V when the amp was delivering 90W to an 8 Ohm load. They shouldn't sag at all.

So I bypassed them and redid the power testing. This time I measured 140W RMS into 8 Ohm at clipping, per channel but not both channels driven simultaneously as I only have one load.

I removed and began troubleshooting the regulators and discovered the main fault lay in the wrong zener choices and not enough voltage overhead to keep them in regulation under load. Another issue to account for is my outlet Voltage tends around 125VAC instead of 117VAC. As such, the 500VA torroid used buzzes. You may recall a similar issue with the HK Citation 7 I resurrected earlier in this forum. It was clearly not designed to run at an elevated outlet voltage and as such, had cooked itself to death: Overheating regulators, heatsinks too hot to touch, toasting the main ckt board, peeling board traces, etc. It's now only turned on with the master switch when needed.

Back to the amp at hand....the regulators are now working properly and no-load to full-load Voltage drop is now within 0.1VDC! Quite an improvement in regulation!

I currently have the MOSFET heatsinks out to install some 0.22 Ohm source resistors. These ensure equal current sharing and provide some source degeneration and local feedback to stabilize the output devices.

I've also removed the driver boards to update the I/O connections from wires directly soldered to the boards to using terminal blocks instead. This greatly enhances board removal and prevents PCB foil damage from repeated in & out.

I'll post photos later. It'll be great having this custom amp back in service. Then I can put the DH220 on the bench. I also have a Parasound 5 ch amp that has begun to hum through the loudspeakers. I suspect the electrolytic caps have aged, the capacitance has fallen and thus noise is getting though the power supply. It may be time for a 're-cap'...litterally.

Stay Tuned!