Originally Posted By: OneEyeJack

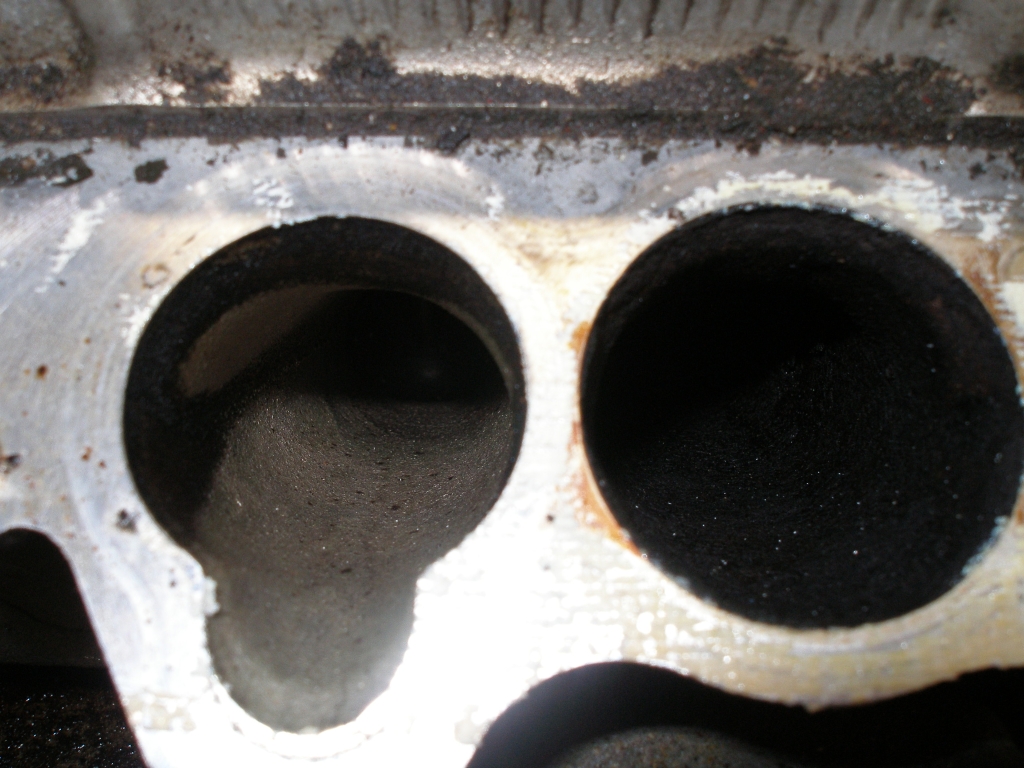

This DI architecture needs more work to get these problems solved. Addition upstream injectors are being added to some engines and this can't be anything other that a direct response to these problems. The push toward this DI stuff is probably a response to smog legislation no matter what the marketing department proposes. It's expensive. If you drive one of the vehicles you probably need to get after the problem from the day you drive off the lot, maybe even confirm the problem with a UOA or two. It appears that you need to get into the intake track upstream from the combustion chamber and include the valves. Chemicals must be used right away to keep up with the problem instead of trying to fix it later. I went through the walnut blast with an Audi even before DI. I don't think I'll be one of those people with a DI engine anytime soon. I can find other ways to help save the earth.

+1

This DI architecture needs more work to get these problems solved. Addition upstream injectors are being added to some engines and this can't be anything other that a direct response to these problems. The push toward this DI stuff is probably a response to smog legislation no matter what the marketing department proposes. It's expensive. If you drive one of the vehicles you probably need to get after the problem from the day you drive off the lot, maybe even confirm the problem with a UOA or two. It appears that you need to get into the intake track upstream from the combustion chamber and include the valves. Chemicals must be used right away to keep up with the problem instead of trying to fix it later. I went through the walnut blast with an Audi even before DI. I don't think I'll be one of those people with a DI engine anytime soon. I can find other ways to help save the earth.

+1