JHZR2

Staff member

That's right, I ordered a pair. Just two, not four... May pick up two more when Im out there later in the year.

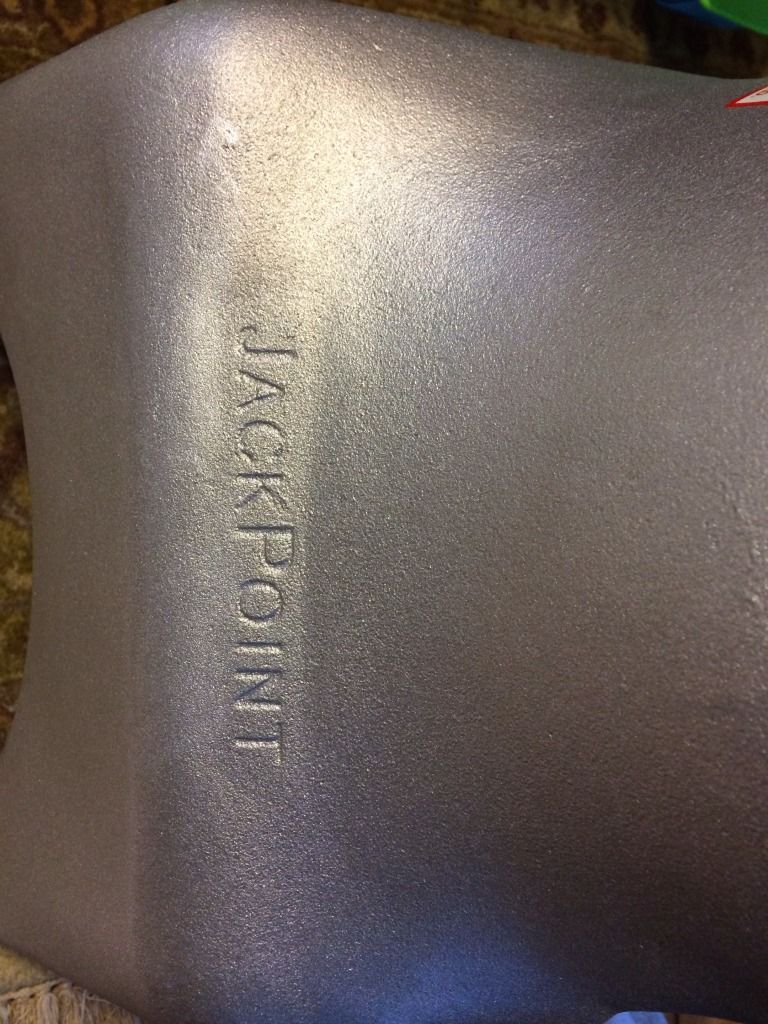

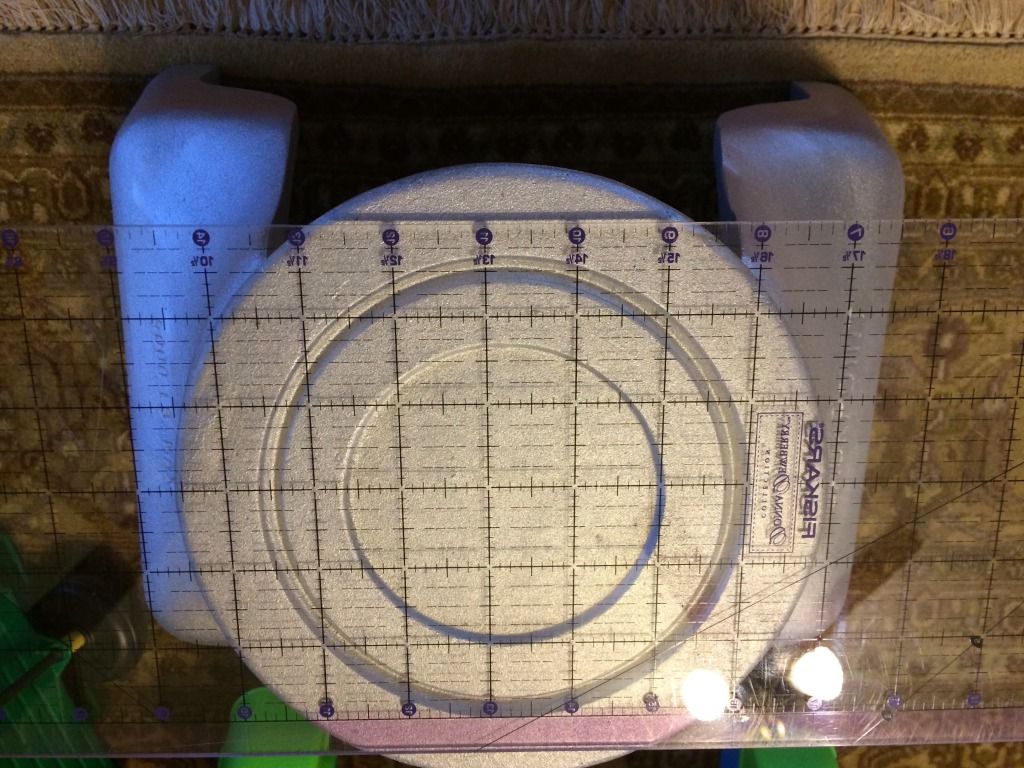

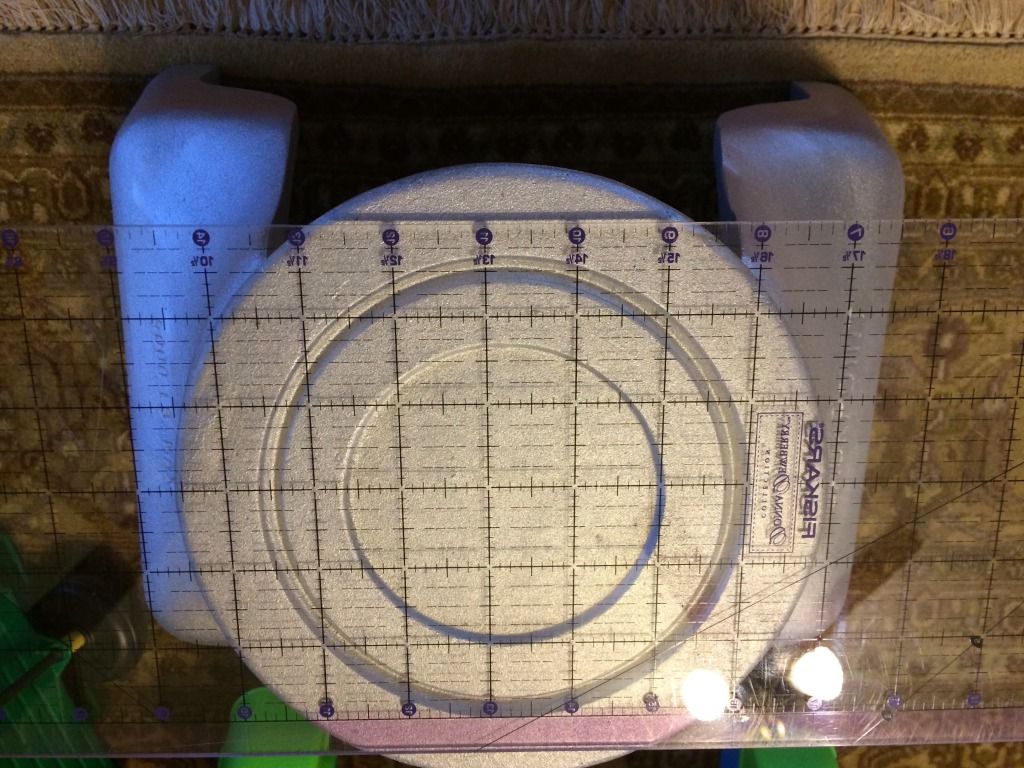

They are a good amount larger than I had thought. Maybe I misjudged by the photos. Still, they are very solid, not that heavy, and its nice that they will nest. I just bought flat tops so that I can adapt with hockey pucks and anything else I need (like square blocks for BMWs, etc.)

Some pictures:

My plan is to use the reverse logic square adapters for cars that need them, and if/when I do pinch welds, Ill identify how to best support them.

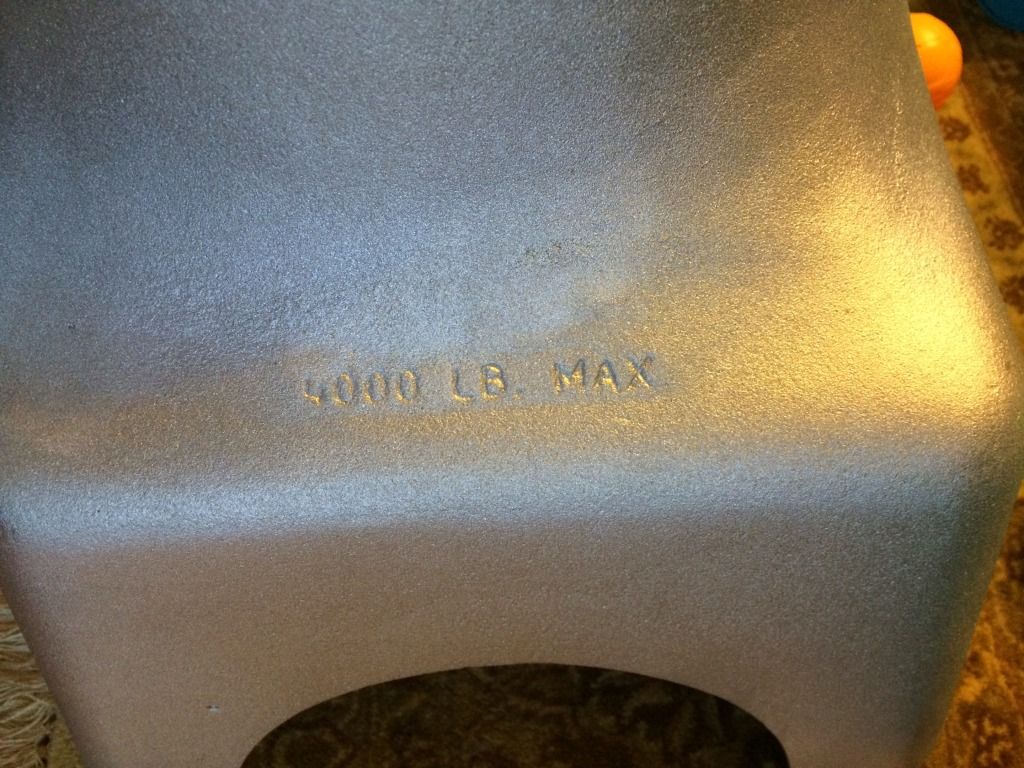

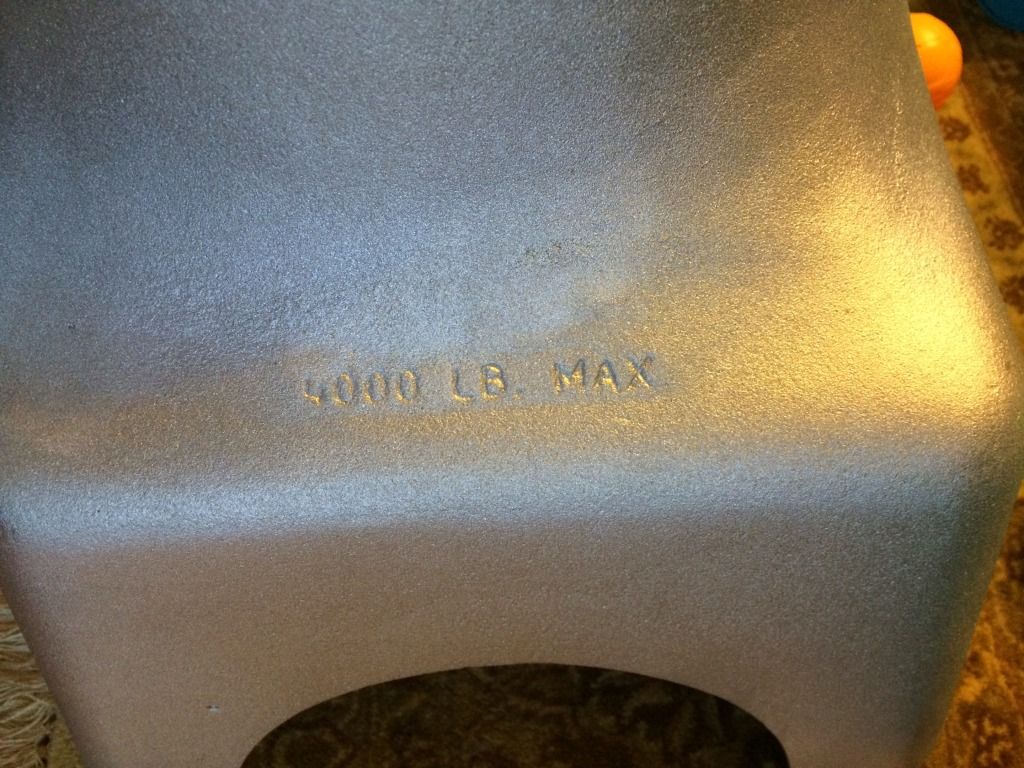

At 4000# each, I wonder if I could use ONE of them under the center brace on the front of the car and have good access. Typically Id never say to use one support, but given the width of the top pad, and assuming the rear wheels are on the ground, it may be stable.

Don't think Id ever do that though... Just thinking out loud... the contact area is HUGE!

They are a good amount larger than I had thought. Maybe I misjudged by the photos. Still, they are very solid, not that heavy, and its nice that they will nest. I just bought flat tops so that I can adapt with hockey pucks and anything else I need (like square blocks for BMWs, etc.)

Some pictures:

My plan is to use the reverse logic square adapters for cars that need them, and if/when I do pinch welds, Ill identify how to best support them.

At 4000# each, I wonder if I could use ONE of them under the center brace on the front of the car and have good access. Typically Id never say to use one support, but given the width of the top pad, and assuming the rear wheels are on the ground, it may be stable.

Don't think Id ever do that though... Just thinking out loud... the contact area is HUGE!