JHZR2

Staff member

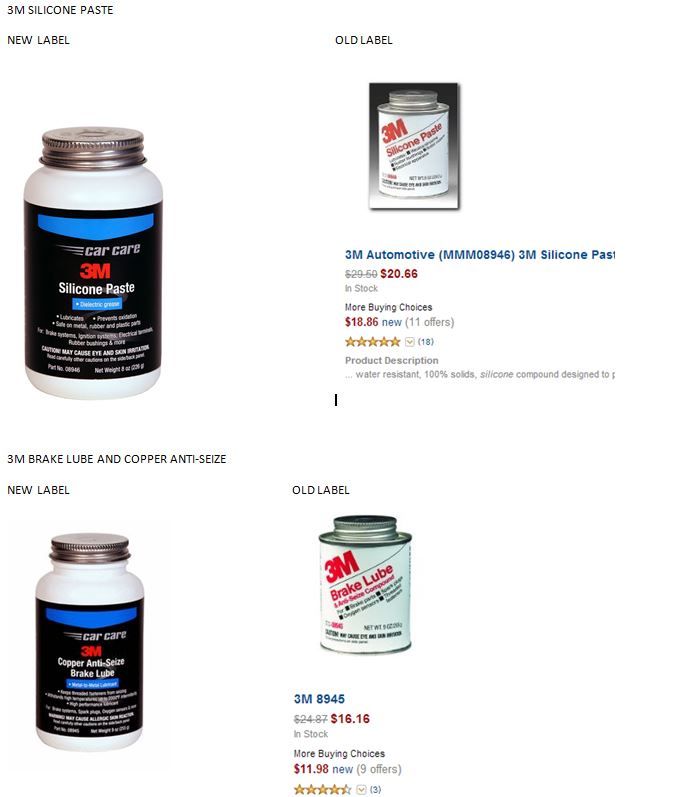

I finished my brake job and bedded in the pads, which stop nicely and work great. I took them out and got them good and hot. Hot enough that my lug bots were hot to the touch. The job was a bit of a pain because I was a bit ill prepared, and AAP wasnt the best either. But the job was done, hopefully right in the end.

I had done the brakes last about 10 years and 80k miles ago. As youll see later, the pads had plenty of meat. I was experiencing an intermittent steering wheel shake when I hit the brake. Didnt happen all the time, which was odd, and I found that the whole front end was solid - no bad ball joints or anything. So the brakes it was. One was sticking.

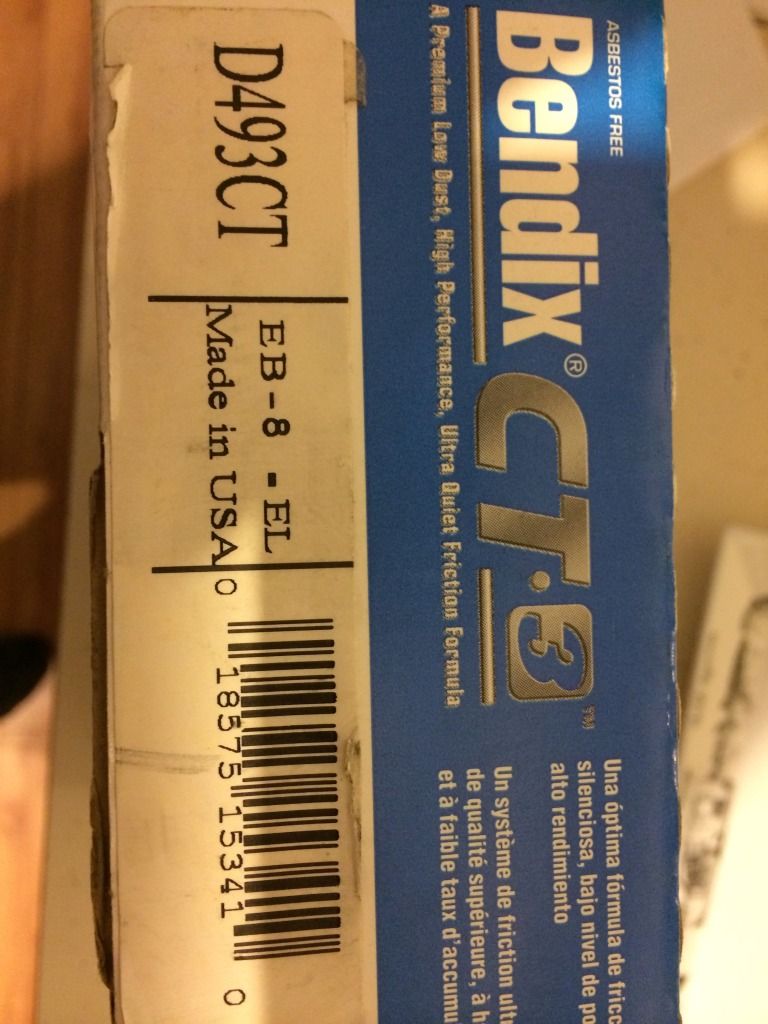

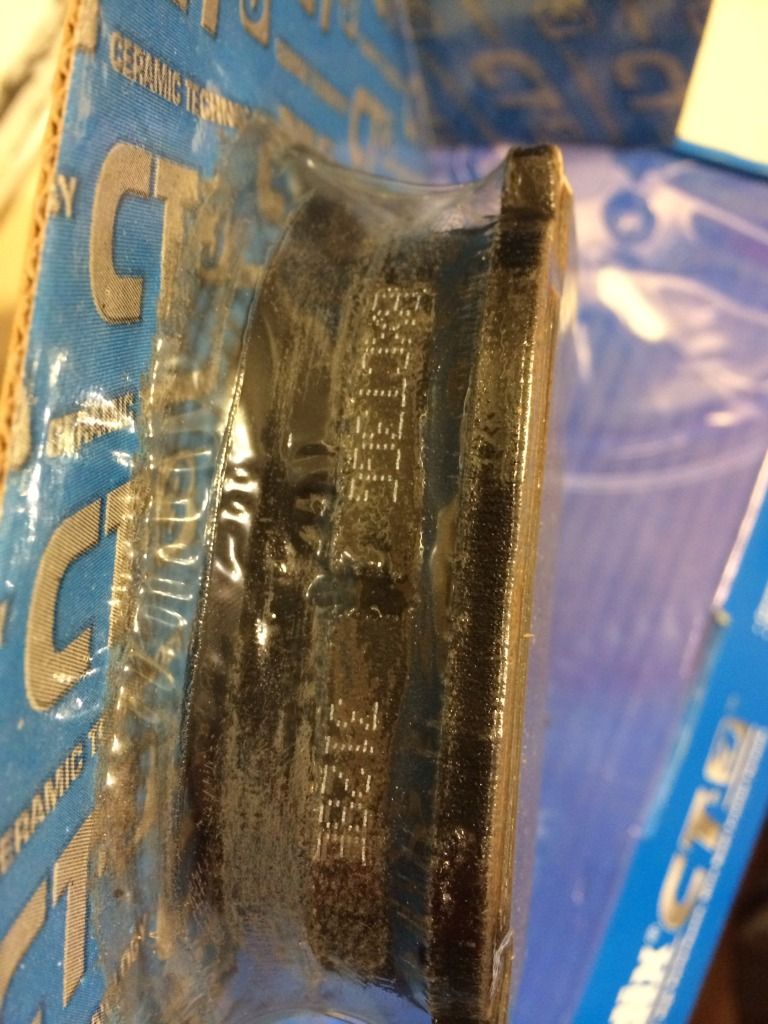

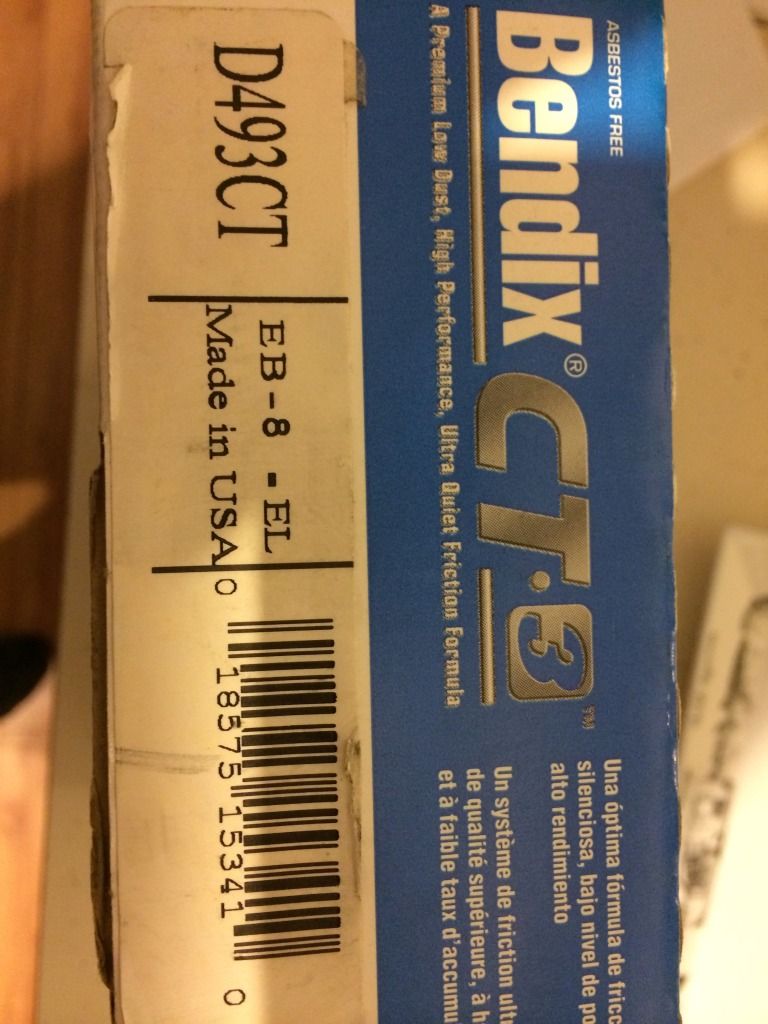

I went with Bendix CT-3 because I like those pads in other applications, and they were $18 from Amazon. I figured that if they were bad, I could always swap them. I think Ill keep them... I also used new Bendix rotors.

So I had originally planned to just swap pads and rotors, but after thinking about it a bit, I realized that I use this car for a lot of driving for work, and the pads and rotors could go another 10 years (though Ill not likely have the car that long due to rust). So I figured it was smart to change the calipers and brake lines too (turned out one side was by necessity anyway...).

Of course folks know my deal about that from my thread about AAP. They sold Fenco rebuilt calipers, which I have to say so far (knock on wood) Ive been happy with. A number of odd inconsistencies such as that one was missing a bracket (QA issue), one was not built, and another was delivered built with greased slide pins and boots. Go figure. The one that came set up I took apart to service myself. They were painted and coated with some sort of lacquer or corrosion preventative. All the threads for the brake lines and bolts were all coated as well and looked perfect. I didnt pay much attention on the first one, but the second one had a very nicely machined piston surface. We will see how they do in the long run, but surely better than a semi-seized one.

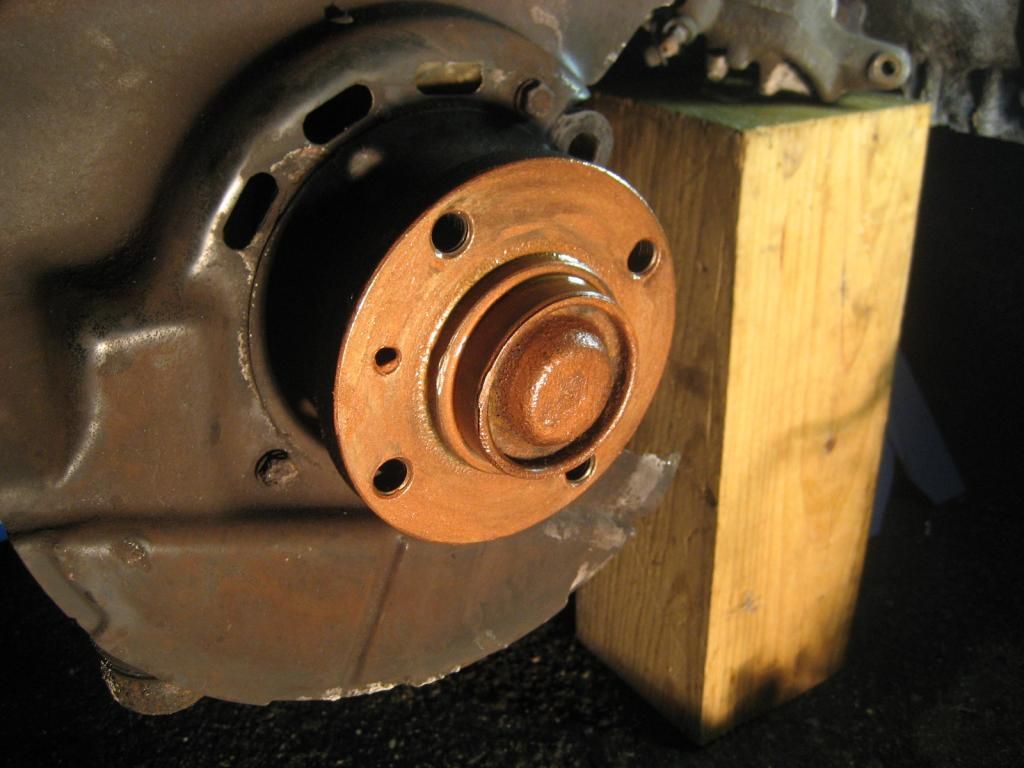

Pulled the first rotor after the issue with the set screw.

The first (left) rotor was decent in terms of shape. In my earlier years I got Zimmerman cross-drilled rotors just because I thought they looked "cool". I looked for evidence of cracking and saw none. This side had very clean holes too. The other side with the semi-seized caliper was a different story.

The first rotor:

The other side wasnt so good...

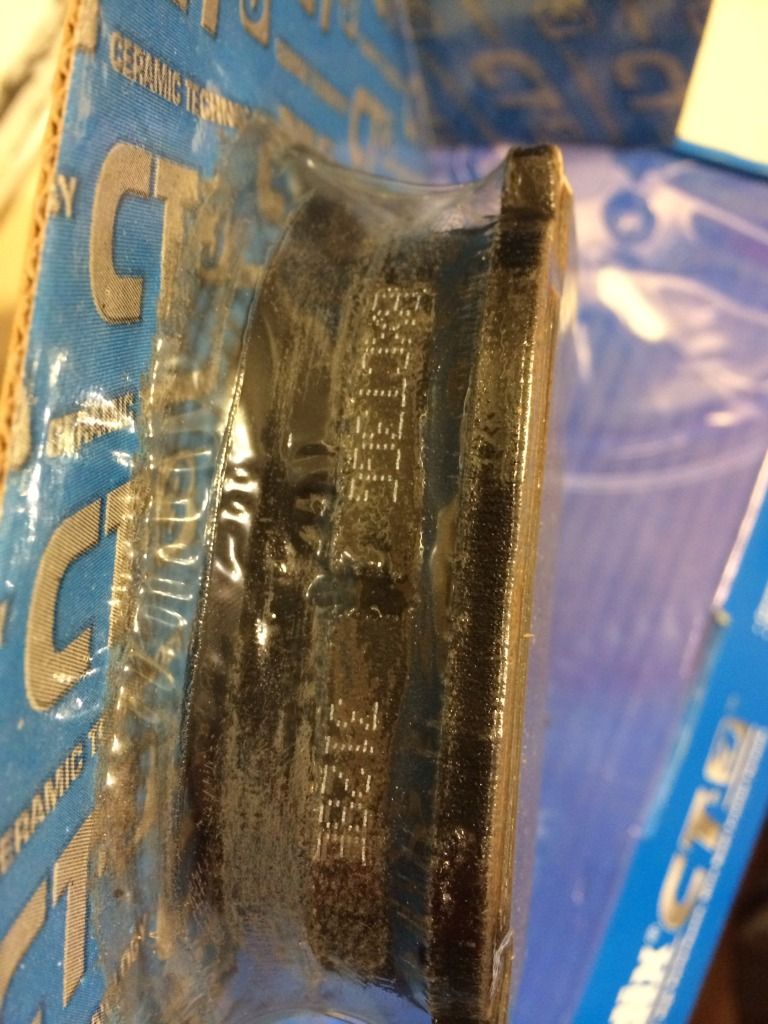

The old pads tell the tale of what happened. The pad on the side with the bad caliper was a little low, but the other side had plenty of pad. Not bad at all given the age and mileage, and given that I drive this car a TON in city and stop and go traffic between DC, NJ, PA and NY. Lots of use of the brakes. Then again I try to drive very gently and the car is light.

These pads were Pagid brand:

And I dont think they had attached shims. I used the CRC red goo generously, and it held the pads, held up and did its job - never any noise from these pads at all.

I had done the brakes last about 10 years and 80k miles ago. As youll see later, the pads had plenty of meat. I was experiencing an intermittent steering wheel shake when I hit the brake. Didnt happen all the time, which was odd, and I found that the whole front end was solid - no bad ball joints or anything. So the brakes it was. One was sticking.

I went with Bendix CT-3 because I like those pads in other applications, and they were $18 from Amazon. I figured that if they were bad, I could always swap them. I think Ill keep them... I also used new Bendix rotors.

So I had originally planned to just swap pads and rotors, but after thinking about it a bit, I realized that I use this car for a lot of driving for work, and the pads and rotors could go another 10 years (though Ill not likely have the car that long due to rust). So I figured it was smart to change the calipers and brake lines too (turned out one side was by necessity anyway...).

Of course folks know my deal about that from my thread about AAP. They sold Fenco rebuilt calipers, which I have to say so far (knock on wood) Ive been happy with. A number of odd inconsistencies such as that one was missing a bracket (QA issue), one was not built, and another was delivered built with greased slide pins and boots. Go figure. The one that came set up I took apart to service myself. They were painted and coated with some sort of lacquer or corrosion preventative. All the threads for the brake lines and bolts were all coated as well and looked perfect. I didnt pay much attention on the first one, but the second one had a very nicely machined piston surface. We will see how they do in the long run, but surely better than a semi-seized one.

Pulled the first rotor after the issue with the set screw.

The first (left) rotor was decent in terms of shape. In my earlier years I got Zimmerman cross-drilled rotors just because I thought they looked "cool". I looked for evidence of cracking and saw none. This side had very clean holes too. The other side with the semi-seized caliper was a different story.

The first rotor:

The other side wasnt so good...

The old pads tell the tale of what happened. The pad on the side with the bad caliper was a little low, but the other side had plenty of pad. Not bad at all given the age and mileage, and given that I drive this car a TON in city and stop and go traffic between DC, NJ, PA and NY. Lots of use of the brakes. Then again I try to drive very gently and the car is light.

These pads were Pagid brand:

And I dont think they had attached shims. I used the CRC red goo generously, and it held the pads, held up and did its job - never any noise from these pads at all.