Hey guys,

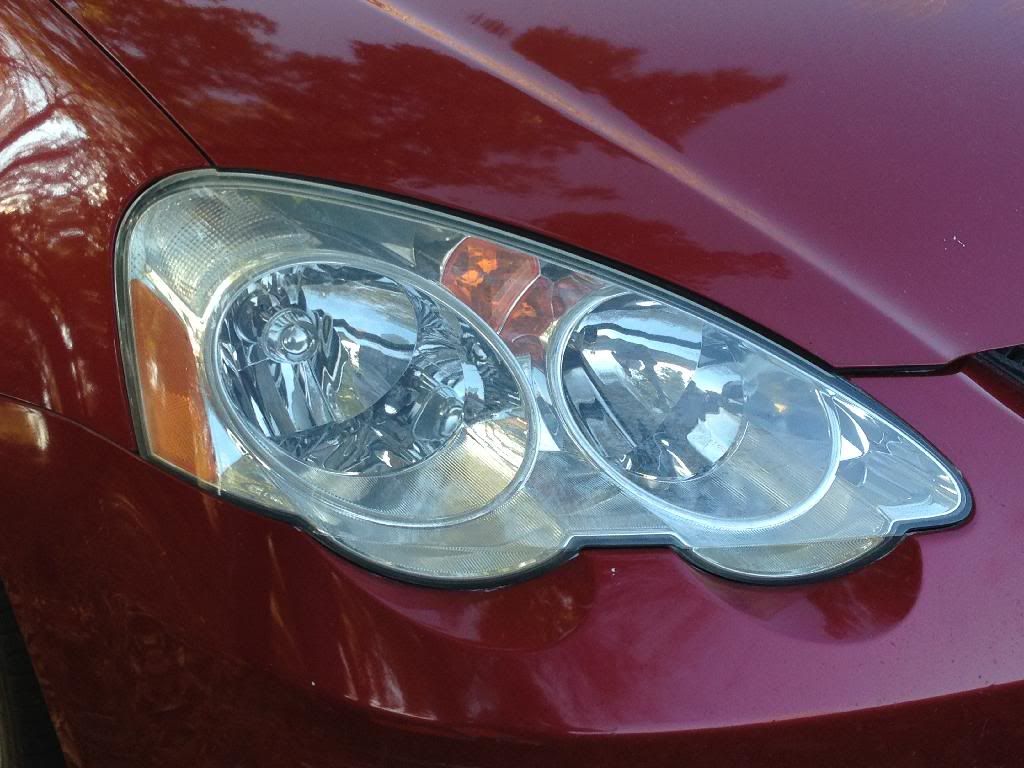

I did a headlight restoration tonight. This is probably the second one that I have ever done. While the owner is very happy with the results, I am not.

After I was done, there was still a very faint haze that I can see under bright overhead florescent lights. I am not sure if the haze can be seen in daylight.

Here was my process. I started with the 3M headlight kit, but I ultimately went to hand-sanding using Meguiars Unigrit sandpaper.

L/F Headlight:

- Dry sand with 3M 500 grit disc w/drill

- Dry sand with 3M 800 grit disc w/drill

- Wet sand with Meg 1500 unigrit by hand

- Compound with rotary, LC purple foam wool and Meguiars M105

- Found traces of 800 grit marks and pigtails…so wet sanded with Meg 1000 unigrit by hand

- Wet sand with Meg 1500 unigrit by hand

- Compound with rotary, LC purple foam wool and Meguiars M105

- Compound with rotary, B&S orange cutting foam pad and Menzerna FG400

- Final polish with Flex 3401, B&S green polishing pad and Sonax Perfect Finish

R/F Headlight:

- Wet sand with Meg 1500 unigrit by hand

- Compound with rotary, LC purple foam wool and Meguiars M105

- Compound with rotary, B&S orange cutting foam pad and Menzerna FG400

- Final polish with Flex 3401, B&S green polishing pad and Sonax Perfect Finish

The L/F headlight turned out a hair clearer than the R/F. However, both of them still have a very faint haze -- they're definitely not as clear as brand-new OE headlights.

Any ideas as to what the issue may be? I do not see any sanding pigtails or sanding marks. Perhaps plastic without a clear coat, is supposed to have a very small amount of haze?

Thanks.

I did a headlight restoration tonight. This is probably the second one that I have ever done. While the owner is very happy with the results, I am not.

After I was done, there was still a very faint haze that I can see under bright overhead florescent lights. I am not sure if the haze can be seen in daylight.

Here was my process. I started with the 3M headlight kit, but I ultimately went to hand-sanding using Meguiars Unigrit sandpaper.

L/F Headlight:

- Dry sand with 3M 500 grit disc w/drill

- Dry sand with 3M 800 grit disc w/drill

- Wet sand with Meg 1500 unigrit by hand

- Compound with rotary, LC purple foam wool and Meguiars M105

- Found traces of 800 grit marks and pigtails…so wet sanded with Meg 1000 unigrit by hand

- Wet sand with Meg 1500 unigrit by hand

- Compound with rotary, LC purple foam wool and Meguiars M105

- Compound with rotary, B&S orange cutting foam pad and Menzerna FG400

- Final polish with Flex 3401, B&S green polishing pad and Sonax Perfect Finish

R/F Headlight:

- Wet sand with Meg 1500 unigrit by hand

- Compound with rotary, LC purple foam wool and Meguiars M105

- Compound with rotary, B&S orange cutting foam pad and Menzerna FG400

- Final polish with Flex 3401, B&S green polishing pad and Sonax Perfect Finish

The L/F headlight turned out a hair clearer than the R/F. However, both of them still have a very faint haze -- they're definitely not as clear as brand-new OE headlights.

Any ideas as to what the issue may be? I do not see any sanding pigtails or sanding marks. Perhaps plastic without a clear coat, is supposed to have a very small amount of haze?

Thanks.