want to share this from M5Board, where we've had string of Rod Bearing failures in the V8 & V10 Motorsport engines

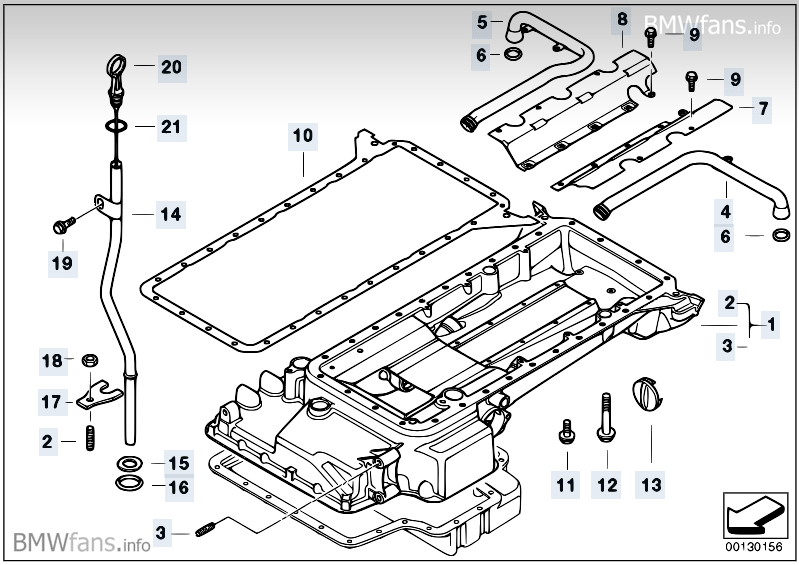

S62B50 V8

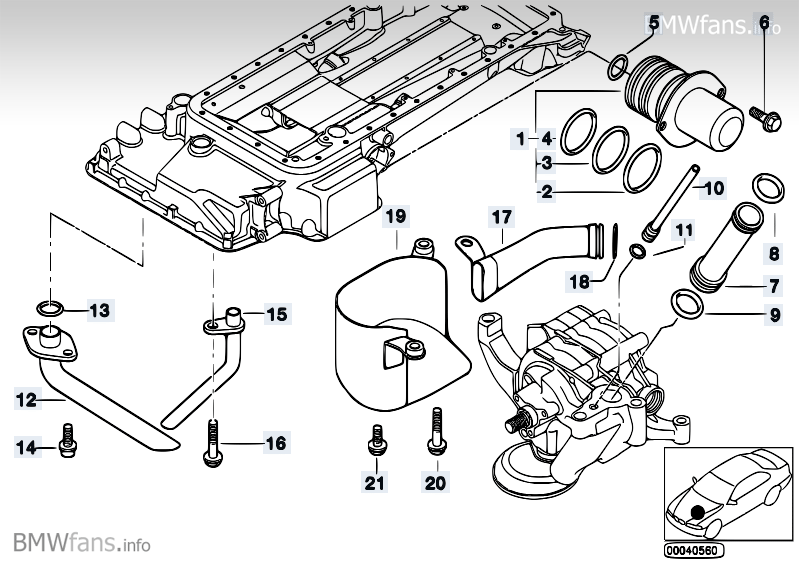

S85B50 V10

both engines are recommended Castrol TWS (10W60), but regardless of the oil used whether 30 weight or 60 weight the UOAs for well maintained cars all come back with the same level of Copper & Lead ~1ppm - 6ppm for both

here's a member (2nd owner) whom planned on doing preventative bearing change and he sent the oil that was in there to blackstone for analysis and what they found was nothing out of the ordinary.

http://www.m5board.com/vbulletin/e60-m5-e61-m5-touring-discussion/283882-rod-bearings-50k-miles.html

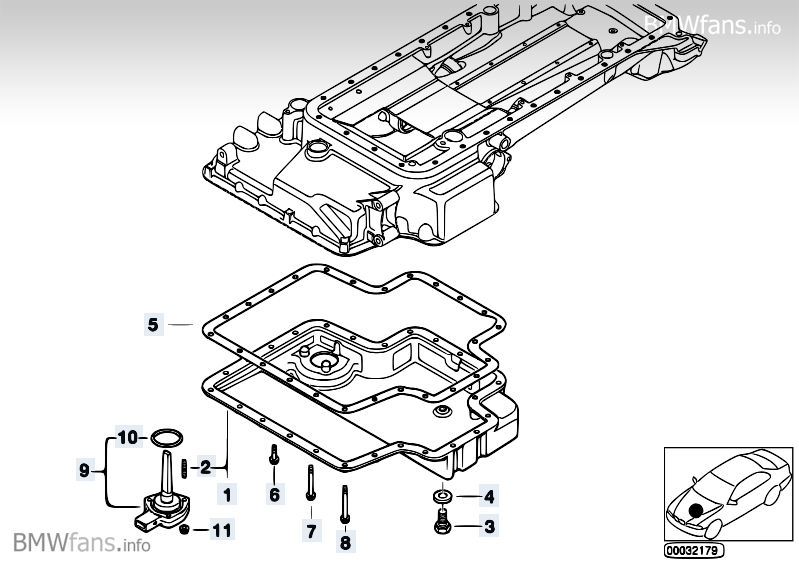

Image of Rod Bearings:

http://www.m5board.com/vbulletin/e60-m5-...tml#post3508129

Blackstone UOA:

http://www.m5board.com/vbulletin/e60-m5-...tml#post3516913

so what are your inputs on this outcome and oil analysis in general?

P.S. not singling out blackstone they just happened to be the place this member sent his oil

S62B50 V8

S85B50 V10

both engines are recommended Castrol TWS (10W60), but regardless of the oil used whether 30 weight or 60 weight the UOAs for well maintained cars all come back with the same level of Copper & Lead ~1ppm - 6ppm for both

here's a member (2nd owner) whom planned on doing preventative bearing change and he sent the oil that was in there to blackstone for analysis and what they found was nothing out of the ordinary.

http://www.m5board.com/vbulletin/e60-m5-e61-m5-touring-discussion/283882-rod-bearings-50k-miles.html

Image of Rod Bearings:

http://www.m5board.com/vbulletin/e60-m5-...tml#post3508129

Blackstone UOA:

http://www.m5board.com/vbulletin/e60-m5-...tml#post3516913

so what are your inputs on this outcome and oil analysis in general?

P.S. not singling out blackstone they just happened to be the place this member sent his oil

Last edited: