You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

07 Chevy 3500, 8.1L 129K, 6K Amsoil ATM 10W30

- Thread starter TXHunter

- Start date

- Status

- Not open for further replies.

Originally Posted By: dnewton3

So is there a virgin number unique to each bottle, or is it fairly consistent for the brand/grade? What would be the delta you expect to see?

Originally Posted By: dnewton3

I realize that there is a differnce out of the bottle, but I didn't understand that it was that large of a descrapancy.

Is that typical of most PAO syns, or just the package in Amsoil?

It varies by formula, depending on the base oils and additive package. And by measurement type. You certainly can't compare labs unless they follow identical methodologies. The "oxidation" number is higher with ester bearing oils. It's a strange myth on BITOG (and other websites) that Amsoil is a "PAO syn". Amsoil uses a decent about of esters and other base oils. Bottom line here is Amsoil should very little delta oxidation number.

So is there a virgin number unique to each bottle, or is it fairly consistent for the brand/grade? What would be the delta you expect to see?

Originally Posted By: dnewton3

I realize that there is a differnce out of the bottle, but I didn't understand that it was that large of a descrapancy.

Is that typical of most PAO syns, or just the package in Amsoil?

It varies by formula, depending on the base oils and additive package. And by measurement type. You certainly can't compare labs unless they follow identical methodologies. The "oxidation" number is higher with ester bearing oils. It's a strange myth on BITOG (and other websites) that Amsoil is a "PAO syn". Amsoil uses a decent about of esters and other base oils. Bottom line here is Amsoil should very little delta oxidation number.

Originally Posted By: dhellman12

I'm not sure the frequency, but I believe he carries 3 wix paper air filters so he can blow them out and rotate until its time to replace.

I'm wondering if this is a great practice or not. Blowing out a paper filter is not generally recommended. Then rotating in a used filter. How are the used ones stored - or am I not reading this correctly.

I think a prefilter would be good here. Just take the prefilter off, knock it out and put it back on without touching the main filter.

I'm not sure the frequency, but I believe he carries 3 wix paper air filters so he can blow them out and rotate until its time to replace.

I'm wondering if this is a great practice or not. Blowing out a paper filter is not generally recommended. Then rotating in a used filter. How are the used ones stored - or am I not reading this correctly.

I think a prefilter would be good here. Just take the prefilter off, knock it out and put it back on without touching the main filter.

Originally Posted By: Pablo

Originally Posted By: dhellman12

I'm not sure the frequency, but I believe he carries 3 wix paper air filters so he can blow them out and rotate until its time to replace.

I'm wondering if this is a great practice or not. Blowing out a paper filter is not generally recommended. Then rotating in a used filter. How are the used ones stored - or am I not reading this correctly.

I think a prefilter would be good here. Just take the prefilter off, knock it out and put it back on without touching the main filter.

I would agree here. get a prefilter or possibly consider just buying a new filter every change. most decent paper filters can be bought for $12-15. this is not much more than your paying per quart for the Amsoil oil. something to consider.

Also sometimes you can get a discount buying bulk filters. see if you could get a better deal buying 10 new filters at a time and just change them every 5-6k miles and eliminate SI worry.

Originally Posted By: dhellman12

I'm not sure the frequency, but I believe he carries 3 wix paper air filters so he can blow them out and rotate until its time to replace.

I'm wondering if this is a great practice or not. Blowing out a paper filter is not generally recommended. Then rotating in a used filter. How are the used ones stored - or am I not reading this correctly.

I think a prefilter would be good here. Just take the prefilter off, knock it out and put it back on without touching the main filter.

I would agree here. get a prefilter or possibly consider just buying a new filter every change. most decent paper filters can be bought for $12-15. this is not much more than your paying per quart for the Amsoil oil. something to consider.

Also sometimes you can get a discount buying bulk filters. see if you could get a better deal buying 10 new filters at a time and just change them every 5-6k miles and eliminate SI worry.

In this app and for the type of service this guy does, why not buy a premium dry filter that can be washed, and perhaps a pre-filter screen on top of it?

Makes more sense than abusing old, used air filters. The fibers are undoubtedly harmed to some extent with each 'cleaning', since they aren't made for this purpose.

Yes, the others covered as well the point on oxidation of virgin Amsoil. The oils here seem to have done fine, not surprisingly. However, air filtration is the prime thing moving forward. How it does, so goes the trends in this app/service conditions.

Makes more sense than abusing old, used air filters. The fibers are undoubtedly harmed to some extent with each 'cleaning', since they aren't made for this purpose.

Yes, the others covered as well the point on oxidation of virgin Amsoil. The oils here seem to have done fine, not surprisingly. However, air filtration is the prime thing moving forward. How it does, so goes the trends in this app/service conditions.

dnewton3

Staff member

Originally Posted By: Pablo

Originally Posted By: dnewton3

So is there a virgin number unique to each bottle, or is it fairly consistent for the brand/grade? What would be the delta you expect to see?

Originally Posted By: dnewton3

I realize that there is a differnce out of the bottle, but I didn't understand that it was that large of a descrapancy.

Is that typical of most PAO syns, or just the package in Amsoil?

It varies by formula, depending on the base oils and additive package. And by measurement type. You certainly can't compare labs unless they follow identical methodologies. The "oxidation" number is higher with ester bearing oils. It's a strange myth on BITOG (and other websites) that Amsoil is a "PAO syn". Amsoil uses a decent about of esters and other base oils. Bottom line here is Amsoil should very little delta oxidation number.

Help me out please; I need to understand more. I must confess my chemical ignorance in this topic.

I would concur that lab-to-lab issues might be a concern, as well as any differing methods used to test oxidation. I get that. However, if I understand this thread correctly, both fluids (in this thread by this OP) were tested by the same lab, so both the lab equipment and methods used would hopefully not be in play. IOW - while that topic might be of interest in a Polaris and CAT and Blackstone topic, these two UOAs are from the same place. I would presume that this portion of the topic is moot; it does not apply.

That simply leaves us with the starting Ox number topic, right? I'll accept the statement that ester based fluids have a higher starting Ox number, but I would like to know WHY, please. Can you elaborate?

And also, is there a "hard ceiling" limit that Ox should not cross over in a report as a condemnation limit?

If so, would that limit be based on a final magnitude, or rather based upon a delta magnitude shift, or a delta percentage shift?

IOW - looking at these two reports, how does one compare/contrast any SHIFT in Ox relative to a condemnation limit? Do you say that a shift of 50 is the limit, or do you say that the ceiling is 150, and allow either to run up that high? Would you condem a fluid for a "X"% oxidation shift?

How does one know?

If we cannot understand the manner to judge the criteria by, it's pretty much meaningless ...

I made the apparant mistake of looking at them on a level playing field. If that is indeed a rookie error, then help me up to the big-league please!

Originally Posted By: dnewton3

So is there a virgin number unique to each bottle, or is it fairly consistent for the brand/grade? What would be the delta you expect to see?

Originally Posted By: dnewton3

I realize that there is a differnce out of the bottle, but I didn't understand that it was that large of a descrapancy.

Is that typical of most PAO syns, or just the package in Amsoil?

It varies by formula, depending on the base oils and additive package. And by measurement type. You certainly can't compare labs unless they follow identical methodologies. The "oxidation" number is higher with ester bearing oils. It's a strange myth on BITOG (and other websites) that Amsoil is a "PAO syn". Amsoil uses a decent about of esters and other base oils. Bottom line here is Amsoil should very little delta oxidation number.

Help me out please; I need to understand more. I must confess my chemical ignorance in this topic.

I would concur that lab-to-lab issues might be a concern, as well as any differing methods used to test oxidation. I get that. However, if I understand this thread correctly, both fluids (in this thread by this OP) were tested by the same lab, so both the lab equipment and methods used would hopefully not be in play. IOW - while that topic might be of interest in a Polaris and CAT and Blackstone topic, these two UOAs are from the same place. I would presume that this portion of the topic is moot; it does not apply.

That simply leaves us with the starting Ox number topic, right? I'll accept the statement that ester based fluids have a higher starting Ox number, but I would like to know WHY, please. Can you elaborate?

And also, is there a "hard ceiling" limit that Ox should not cross over in a report as a condemnation limit?

If so, would that limit be based on a final magnitude, or rather based upon a delta magnitude shift, or a delta percentage shift?

IOW - looking at these two reports, how does one compare/contrast any SHIFT in Ox relative to a condemnation limit? Do you say that a shift of 50 is the limit, or do you say that the ceiling is 150, and allow either to run up that high? Would you condem a fluid for a "X"% oxidation shift?

How does one know?

If we cannot understand the manner to judge the criteria by, it's pretty much meaningless ...

I made the apparant mistake of looking at them on a level playing field. If that is indeed a rookie error, then help me up to the big-league please!

Last edited:

Originally Posted By: dnewton3

Help me out please; I need to understand more. I must confess my chemical ignorance in this topic.

I would concur that lab-to-lab issues might be a concern, as well as any differing methods used to test oxidation. I get that. However, if I understand this thread correctly, both fluids (in this thread by this OP) were tested by the same lab, so both the lab equipment and methods used would hopefully not be in play. IOW - while that topic might be of interest in a Polaris and CAT and Blackstone topic, these two UOAs are from the same place. I would presume that this portion of the topic is moot; it does not apply.

It may not apply to this thread, but it always applies when accumulating data or doing the BITOG UOA section perusal. Completely different scales are used, for example.

Originally Posted By: dnewton3

That simply leaves us with the starting Ox number topic, right? I'll accept the statement that ester based fluids have a higher starting Ox number, but I would like to know WHY, please. Can you elaborate?

And also, is there a "hard ceiling" limit that Ox should not cross over in a report as a condemnation limit?

If so, would that limit be based on a final magnitude, or rather based upon a delta magnitude shift, or a delta percentage shift?

IOW - looking at these two reports, how does one compare/contrast any SHIFT in Ox relative to a condemnation limit? Do you say that a shift of 50 is the limit, or do you say that the ceiling is 150, and allow either to run up that high? Would you condem a fluid for a "X"% oxidation shift?

How does one know?

If we cannot understand the manner to judge the criteria by, it's pretty much meaningless ...

I made the apparant mistake of looking at them on a level playing field. If that is indeed a rookie error, then help me up to the big-league please!

In simple, concise terms: because of the Oxygen in esters, in simple chemical terms the carbonyl adjacent to the ether linkage - two sets of 0 atoms, that very much have the same wavelength as oxidized carbon chains and such.

Good question on the condemnation limit. Worthy of asking labs and real experts. Depending on the fluid, sometimes I have read "75% of allowable". But what is allowable? I could interpret that to mean virgin + 75%. So and oil with a virgin reading of say 40, condemnation would be 70. I would make it mentionable in a UOA if someone posted a virgin number and it increased 50% or so - start looking for the causes. Excessive heat, malfunctioning breathing system, etc

Indeed rookie error. I have brought up the fact the oxidation number is useless with out a virgin number many times over the years. It would be an good topic for Molakule or other expert to cover here.

Help me out please; I need to understand more. I must confess my chemical ignorance in this topic.

I would concur that lab-to-lab issues might be a concern, as well as any differing methods used to test oxidation. I get that. However, if I understand this thread correctly, both fluids (in this thread by this OP) were tested by the same lab, so both the lab equipment and methods used would hopefully not be in play. IOW - while that topic might be of interest in a Polaris and CAT and Blackstone topic, these two UOAs are from the same place. I would presume that this portion of the topic is moot; it does not apply.

It may not apply to this thread, but it always applies when accumulating data or doing the BITOG UOA section perusal. Completely different scales are used, for example.

Originally Posted By: dnewton3

That simply leaves us with the starting Ox number topic, right? I'll accept the statement that ester based fluids have a higher starting Ox number, but I would like to know WHY, please. Can you elaborate?

And also, is there a "hard ceiling" limit that Ox should not cross over in a report as a condemnation limit?

If so, would that limit be based on a final magnitude, or rather based upon a delta magnitude shift, or a delta percentage shift?

IOW - looking at these two reports, how does one compare/contrast any SHIFT in Ox relative to a condemnation limit? Do you say that a shift of 50 is the limit, or do you say that the ceiling is 150, and allow either to run up that high? Would you condem a fluid for a "X"% oxidation shift?

How does one know?

If we cannot understand the manner to judge the criteria by, it's pretty much meaningless ...

I made the apparant mistake of looking at them on a level playing field. If that is indeed a rookie error, then help me up to the big-league please!

In simple, concise terms: because of the Oxygen in esters, in simple chemical terms the carbonyl adjacent to the ether linkage - two sets of 0 atoms, that very much have the same wavelength as oxidized carbon chains and such.

Good question on the condemnation limit. Worthy of asking labs and real experts. Depending on the fluid, sometimes I have read "75% of allowable". But what is allowable? I could interpret that to mean virgin + 75%. So and oil with a virgin reading of say 40, condemnation would be 70. I would make it mentionable in a UOA if someone posted a virgin number and it increased 50% or so - start looking for the causes. Excessive heat, malfunctioning breathing system, etc

Indeed rookie error. I have brought up the fact the oxidation number is useless with out a virgin number many times over the years. It would be an good topic for Molakule or other expert to cover here.

dnewton3

Staff member

OK -

So if I understand, conceptually it's similar to the Si issue; silicone and silica are seen as the same thing in a UOA (indistinguishable basically). The same could be said of the oxidation issue, in that the ester has elements that the testing cannot distinguish between true oxidation and held oxygen? If I have that right, I can understand the descrapancy of the testing results is these reports.

Also seems that condemnation limits might be a bit of a "feel good or not" limit, as opposed to a hard limit. Similar to TBN condemnation then? And certainly would be harder to define with the challenge as described above, distinguishing real oxidized components versus ghost/masking elements?

Question: do the chained oxygen elements ever become free (essentially radicalized), thereby changing the count? IOW - could it be that degredation of the ester (and subsequesnt release of oxygen) offsets the real oxidation uptick of the other components, and falsely lower the count?

So if I understand, conceptually it's similar to the Si issue; silicone and silica are seen as the same thing in a UOA (indistinguishable basically). The same could be said of the oxidation issue, in that the ester has elements that the testing cannot distinguish between true oxidation and held oxygen? If I have that right, I can understand the descrapancy of the testing results is these reports.

Also seems that condemnation limits might be a bit of a "feel good or not" limit, as opposed to a hard limit. Similar to TBN condemnation then? And certainly would be harder to define with the challenge as described above, distinguishing real oxidized components versus ghost/masking elements?

Question: do the chained oxygen elements ever become free (essentially radicalized), thereby changing the count? IOW - could it be that degredation of the ester (and subsequesnt release of oxygen) offsets the real oxidation uptick of the other components, and falsely lower the count?

Last edited:

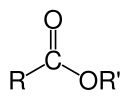

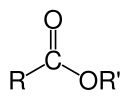

Pablo covered the chemical description. Here's the structure of an ester:

You are correct in your Silicone-SiO2 analogy. The methods used to determine oxidation are looking for oxygen bonds. The higher the number of bonds seen, the higher the oxidation value reported. If FTIR is used, it would be possible to correct for the esters, but not at the price of a UOA.

Oxygen is going to want to stay bonded. It won't go away. It is possible for chemical reactions to occur that form new compounds, most likely at the double bond. It will still show as correctly as "oxidation" in a UOA.

Ed

You are correct in your Silicone-SiO2 analogy. The methods used to determine oxidation are looking for oxygen bonds. The higher the number of bonds seen, the higher the oxidation value reported. If FTIR is used, it would be possible to correct for the esters, but not at the price of a UOA.

Oxygen is going to want to stay bonded. It won't go away. It is possible for chemical reactions to occur that form new compounds, most likely at the double bond. It will still show as correctly as "oxidation" in a UOA.

Ed

IMO, oils of a similar starting Virgin state wrt oxidation as the Amsoil, it's basically a useless number unless it were to rise quite a bit.

By that point, you'd imagine some other condemnation limit would be reached with such a lube. However, conventional oils or one's without such a high base reading may be another story. Still, I would tend to think some other factor would trigger the oil being past service limits if oxidation were ever abnormal for the lube.

What goes hand in hand with higher oxidation? You got me there. Still, a used lube in passenger cars will have rising TAN, depleting TBN, the concern over any contaminants or viscosity; amongst the other base line data we all tend to look at when seeing if an oil is suitable for continued use.

By that point, you'd imagine some other condemnation limit would be reached with such a lube. However, conventional oils or one's without such a high base reading may be another story. Still, I would tend to think some other factor would trigger the oil being past service limits if oxidation were ever abnormal for the lube.

What goes hand in hand with higher oxidation? You got me there. Still, a used lube in passenger cars will have rising TAN, depleting TBN, the concern over any contaminants or viscosity; amongst the other base line data we all tend to look at when seeing if an oil is suitable for continued use.

dnewton3

Staff member

Well I'm taking away from this more than I brought in, that's for sure.

Clearly ox numbers are pretty much worthless without any frame of reference; the delta would be much more important than the origin; Pablo is correct.

But that really doesn't give me a "warm and fuzzy" feeling about what delta is acceptable. Would it be different for each product, or each base stock, or what? Is it fair to say that an ester-based lube product can ignore oxidation, while a "lesser" lube cannot? Is a lesser lube more suspectible to oxidation? Would the delta shift occur quicker in a lesser lube, if all othe conditions were to be held the same?

I think I now can grasp the front end of the discussion, but I also see that the back end is muddled. It really does not give any person any ability to judge the ox factor, regardless. While we might be able to say that a much higher ox reading on a singular UOA could be ignored, I don't know that we could say what is bad or good at this point. What delta shift is acceptable? 20%? 50%? 80%? Is the ox degredation trend linear or parabolic? The TBN/TAN reactions are most certainly parabolic; would that be true of the oxidation response of any lube, let alone and ester-based lube?

TBN is a bit different; there is generally a floor limit, regardless of it's starting point, and regardless of the lube base stock. That's much easier to define a condemtnation limit.

What can the OP dhellman12 take away from his report? The Amsoil starts with a much higher ox value, but what level could it rise to before concern should become noteworthy? He indicated that extended OCIs were the intent; where's his condemantion point? Without being able to define/describe a limit, the ox number (regardless of it's origin) is a worthless number in the UOA. And while I understand Pablo's position (origin is meaningless because of different base stock composition), it's even moreso useless if one cannot decide where to draw the terminal line ...

Clearly ox numbers are pretty much worthless without any frame of reference; the delta would be much more important than the origin; Pablo is correct.

But that really doesn't give me a "warm and fuzzy" feeling about what delta is acceptable. Would it be different for each product, or each base stock, or what? Is it fair to say that an ester-based lube product can ignore oxidation, while a "lesser" lube cannot? Is a lesser lube more suspectible to oxidation? Would the delta shift occur quicker in a lesser lube, if all othe conditions were to be held the same?

I think I now can grasp the front end of the discussion, but I also see that the back end is muddled. It really does not give any person any ability to judge the ox factor, regardless. While we might be able to say that a much higher ox reading on a singular UOA could be ignored, I don't know that we could say what is bad or good at this point. What delta shift is acceptable? 20%? 50%? 80%? Is the ox degredation trend linear or parabolic? The TBN/TAN reactions are most certainly parabolic; would that be true of the oxidation response of any lube, let alone and ester-based lube?

TBN is a bit different; there is generally a floor limit, regardless of it's starting point, and regardless of the lube base stock. That's much easier to define a condemtnation limit.

What can the OP dhellman12 take away from his report? The Amsoil starts with a much higher ox value, but what level could it rise to before concern should become noteworthy? He indicated that extended OCIs were the intent; where's his condemantion point? Without being able to define/describe a limit, the ox number (regardless of it's origin) is a worthless number in the UOA. And while I understand Pablo's position (origin is meaningless because of different base stock composition), it's even moreso useless if one cannot decide where to draw the terminal line ...

Last edited:

Seems to me, some point at 75%. Please contact 2-3 labs.

A percentage increase in oxidation as a condemnation doesn't work well because if one oil's virgin oxidation number is 0, the condemnation would also be zero. I think the condemnation should be simply an increase in the value.

Oxidation typically rises slowly and gradually while the antioxidants are in good shape but when their concentration gets low, oxidation typically sharply increases. Look for viscosity increases when looking at oxidation values becauses oxidation increases the molecule size of what gets oxidized. Keep in mind that many oils will lose viscosity early on in gasoline engines from polymeric VII breakup, then viscosity will start to rise as oxidation occurs. So the viscosity increase is from the lowest viscosity that the oil reached, not from the virgin oil's viscosity.

Oxidation typically rises slowly and gradually while the antioxidants are in good shape but when their concentration gets low, oxidation typically sharply increases. Look for viscosity increases when looking at oxidation values becauses oxidation increases the molecule size of what gets oxidized. Keep in mind that many oils will lose viscosity early on in gasoline engines from polymeric VII breakup, then viscosity will start to rise as oxidation occurs. So the viscosity increase is from the lowest viscosity that the oil reached, not from the virgin oil's viscosity.

Originally Posted By: Pablo

Originally Posted By: dhellman12

I'm not sure the frequency, but I believe he carries 3 wix paper air filters so he can blow them out and rotate until its time to replace.

I think a prefilter would be good here. Just take the prefilter off, knock it out and put it back on without touching the main filter.

+1 an excellent point so far as 'blocking the dirt via air filter is concerned'.

However, it can interfere with the optimized air supply as per manufacturer design, which may hurt fuel economy/efficiency!

Originally Posted By: dhellman12

I'm not sure the frequency, but I believe he carries 3 wix paper air filters so he can blow them out and rotate until its time to replace.

I think a prefilter would be good here. Just take the prefilter off, knock it out and put it back on without touching the main filter.

+1 an excellent point so far as 'blocking the dirt via air filter is concerned'.

However, it can interfere with the optimized air supply as per manufacturer design, which may hurt fuel economy/efficiency!

Originally Posted By: JAG

A percentage increase in oxidation as a condemnation doesn't work well because if one oil's virgin oxidation number is 0, the condemnation would also be zero. I think the condemnation should be simply an increase in the value.

I understand mathematically. But does any oil start at zero? I do agree with you - either way - to use the the oxidation and nitration numbers, it must be an exact formulation to/by formulation comparison. And one must know the formulation to put the numbers to good use OR just have a long string of the same oil UOA's.

A percentage increase in oxidation as a condemnation doesn't work well because if one oil's virgin oxidation number is 0, the condemnation would also be zero. I think the condemnation should be simply an increase in the value.

I understand mathematically. But does any oil start at zero? I do agree with you - either way - to use the the oxidation and nitration numbers, it must be an exact formulation to/by formulation comparison. And one must know the formulation to put the numbers to good use OR just have a long string of the same oil UOA's.

Originally Posted By: fpracha

+1 an excellent point so far as 'blocking the dirt via air filter is concerned'.

However, it can interfere with the optimized air supply as per manufacturer design, which may hurt fuel economy/efficiency!

So would a clogged filter. A prefilter requires frequent perhaps daily cleaning. There are always trade-offs in sub-optimal conditions.

+1 an excellent point so far as 'blocking the dirt via air filter is concerned'.

However, it can interfere with the optimized air supply as per manufacturer design, which may hurt fuel economy/efficiency!

So would a clogged filter. A prefilter requires frequent perhaps daily cleaning. There are always trade-offs in sub-optimal conditions.

Originally Posted By: Pablo

Originally Posted By: JAG

A percentage increase in oxidation as a condemnation doesn't work well because if one oil's virgin oxidation number is 0, the condemnation would also be zero. I think the condemnation should be simply an increase in the value.

I understand mathematically. But does any oil start at zero? I do agree with you - either way - to use the the oxidation and nitration numbers, it must be an exact formulation to/by formulation comparison. And one must know the formulation to put the numbers to good use OR just have a long string of the same oil UOA's.

Yes I've seen VOAs with oxidation of zero.

Originally Posted By: JAG

A percentage increase in oxidation as a condemnation doesn't work well because if one oil's virgin oxidation number is 0, the condemnation would also be zero. I think the condemnation should be simply an increase in the value.

I understand mathematically. But does any oil start at zero? I do agree with you - either way - to use the the oxidation and nitration numbers, it must be an exact formulation to/by formulation comparison. And one must know the formulation to put the numbers to good use OR just have a long string of the same oil UOA's.

Yes I've seen VOAs with oxidation of zero.

Originally Posted By: JAG

A percentage increase in oxidation as a condemnation doesn't work well because if one oil's virgin oxidation number is 0, the condemnation would also be zero. I think the condemnation should be simply an increase in the value.

Oxidation typically rises slowly and gradually while the antioxidants are in good shape but when their concentration gets low, oxidation typically sharply increases. Look for viscosity increases when looking at oxidation values becauses oxidation increases the molecule size of what gets oxidized. Keep in mind that many oils will lose viscosity early on in gasoline engines from polymeric VII breakup, then viscosity will start to rise as oxidation occurs. So the viscosity increase is from the lowest viscosity that the oil reached, not from the virgin oil's viscosity.

+1

Look for viscosity increases.

A percentage increase in oxidation as a condemnation doesn't work well because if one oil's virgin oxidation number is 0, the condemnation would also be zero. I think the condemnation should be simply an increase in the value.

Oxidation typically rises slowly and gradually while the antioxidants are in good shape but when their concentration gets low, oxidation typically sharply increases. Look for viscosity increases when looking at oxidation values becauses oxidation increases the molecule size of what gets oxidized. Keep in mind that many oils will lose viscosity early on in gasoline engines from polymeric VII breakup, then viscosity will start to rise as oxidation occurs. So the viscosity increase is from the lowest viscosity that the oil reached, not from the virgin oil's viscosity.

+1

Look for viscosity increases.

dnewton3

Staff member

Well - again I would ask, to what condemnation level?

OK - so we look for a vis increase to coincide with the shift in oxidation. Fine. But to what limit? How much thickening is too much thickening?

I have a great example; a few years ago I ran my Dmax on dino 10w-30 and it thickened to a 40 grade. Oxidation obviously occured, but to what detrimental effect? None, really. The wear rates were as steady as a rock, and were still moving down.

Vis is affected by more than oxidation; soot and other insolubles contribute as well. So I'd have to ask about these concepts:

1) how much shift in vis is attributed to true oxidation, versus other contributors?

2) how can we quantify and track the negative effects of vis increase?

3) how much shift in vis can be safely tolerated?

Nearly any oil will first shear a bit, and then thicken from the aging (oxidation and other insolubles).

Could we find UOAs that would help us differentiate good/poor wear performance that was directly attributed to the oxdiation concern? Is there good evidence that shows we could manage the oxidation concern as a controlable input, and thereby affect the output of wear rates?

We should be very careful to not confuse correlation with causation.

An increase in vis does not equal an automatic increase in wear rates; there are plenty of examples that show no correlation whatsoever at lower levels of delta shift. An increase in vis due to an increase in oxidation will not automatically manifest into higher wear. At some point with gross shifts? Yes. But not shifts within a grade range that is already acceptable.

Would a delta shift of +40% in oxidation direct result in a 40% increase in vis? Doubtful ...

Would a delta shift in vis +10% result in a 10% increase in wear? Doubtful ...

The more I understand this topic (from a basic level), the more I really don't see it's direct value in a UOA. It's more of an input than an output. When wear is good, and contamination is low, the others are mearly items to muse over toward the end result.

Because what I'm hearing (and correct me if I'm wrong) is that oxidation isn't going to directly affect wear; it's an indirect relationship, and probably has a very muted effect at lesser magnitudes. And we can see evidence of that many times over. We see oils that shear, and yet have acceptable wear rates. We see oils that thicken, and have good wear rates. Only if the oil GROSSLY is affected by oxidation, would the wear rate shift.

If I'm off base here, then I'd have to ask to see the data trends in UOAs. I'd need to see proof.

And I can point to the SAE study (2007-01-4133) that clearly shows some oxidation is good. In that study, the oils were run out to 15k miles, and the vis most certainly thickened. And yet wear rates were still DROPPING that far out. And it was NOT PAOs or Esters that were being tested; it was GF-3 and GF-4 fluids rather than boutique high-end lubes. And my UOA data also shows that while vis changes (some of it from ox, some from other insolubles), the wear rates confirm the SAE study data.

I appreciate the chemistry lesson. But I'm just about convinced that oxidation is (nearly) a moot point. Only if it were SERIOUSLY shifted in an VERY EXAGGERATED manner, would it mean anything at all. Regardless of base stock.

OK - so we look for a vis increase to coincide with the shift in oxidation. Fine. But to what limit? How much thickening is too much thickening?

I have a great example; a few years ago I ran my Dmax on dino 10w-30 and it thickened to a 40 grade. Oxidation obviously occured, but to what detrimental effect? None, really. The wear rates were as steady as a rock, and were still moving down.

Vis is affected by more than oxidation; soot and other insolubles contribute as well. So I'd have to ask about these concepts:

1) how much shift in vis is attributed to true oxidation, versus other contributors?

2) how can we quantify and track the negative effects of vis increase?

3) how much shift in vis can be safely tolerated?

Nearly any oil will first shear a bit, and then thicken from the aging (oxidation and other insolubles).

Could we find UOAs that would help us differentiate good/poor wear performance that was directly attributed to the oxdiation concern? Is there good evidence that shows we could manage the oxidation concern as a controlable input, and thereby affect the output of wear rates?

We should be very careful to not confuse correlation with causation.

An increase in vis does not equal an automatic increase in wear rates; there are plenty of examples that show no correlation whatsoever at lower levels of delta shift. An increase in vis due to an increase in oxidation will not automatically manifest into higher wear. At some point with gross shifts? Yes. But not shifts within a grade range that is already acceptable.

Would a delta shift of +40% in oxidation direct result in a 40% increase in vis? Doubtful ...

Would a delta shift in vis +10% result in a 10% increase in wear? Doubtful ...

The more I understand this topic (from a basic level), the more I really don't see it's direct value in a UOA. It's more of an input than an output. When wear is good, and contamination is low, the others are mearly items to muse over toward the end result.

Because what I'm hearing (and correct me if I'm wrong) is that oxidation isn't going to directly affect wear; it's an indirect relationship, and probably has a very muted effect at lesser magnitudes. And we can see evidence of that many times over. We see oils that shear, and yet have acceptable wear rates. We see oils that thicken, and have good wear rates. Only if the oil GROSSLY is affected by oxidation, would the wear rate shift.

If I'm off base here, then I'd have to ask to see the data trends in UOAs. I'd need to see proof.

And I can point to the SAE study (2007-01-4133) that clearly shows some oxidation is good. In that study, the oils were run out to 15k miles, and the vis most certainly thickened. And yet wear rates were still DROPPING that far out. And it was NOT PAOs or Esters that were being tested; it was GF-3 and GF-4 fluids rather than boutique high-end lubes. And my UOA data also shows that while vis changes (some of it from ox, some from other insolubles), the wear rates confirm the SAE study data.

I appreciate the chemistry lesson. But I'm just about convinced that oxidation is (nearly) a moot point. Only if it were SERIOUSLY shifted in an VERY EXAGGERATED manner, would it mean anything at all. Regardless of base stock.

Last edited:

Originally Posted By: dnewton3

Well - again I would ask, to what condemnation level?

OK - so we look for a vis increase to coincide with the shift in oxidation. Fine. But to what limit? How much thickening is too much thickening?

I appreciate the chemistry lesson. But I'm just about convinced that oxidation is (nearly) a moot point. Only if it were SERIOUSLY shifted in an VERY EXAGGERATED manner, would it mean anything at all. Regardless of base stock.

+1.

It's not for determining condemnation level.

Ox is related to quality of the base oil and significant only when an oil's performance is really tested in the application (either high loads or high temperatures due to continuous operation or both).

Well - again I would ask, to what condemnation level?

OK - so we look for a vis increase to coincide with the shift in oxidation. Fine. But to what limit? How much thickening is too much thickening?

I appreciate the chemistry lesson. But I'm just about convinced that oxidation is (nearly) a moot point. Only if it were SERIOUSLY shifted in an VERY EXAGGERATED manner, would it mean anything at all. Regardless of base stock.

+1.

It's not for determining condemnation level.

Ox is related to quality of the base oil and significant only when an oil's performance is really tested in the application (either high loads or high temperatures due to continuous operation or both).

- Status

- Not open for further replies.

Similar threads

- Replies

- 16

- Views

- 2K

- Replies

- 29

- Views

- 6K

- Replies

- 2

- Views

- 1K

- Locked

- Replies

- 11

- Views

- 3K