JHZR2

Staff member

Hi,

My 98 Chevy S-10 ZR2 doesnt get a lot of use. Started it today, turned on the A/C (80F and pretty humid), and found it short cycling, though plenty cold.

Ive never touched the A/C, never added any refrigerant, etc. I thought I noticed the engagement being shorter and shorter, but it was not any big concern. I suppose I should have been a bit more proactive, but dont drive the truck a ton.

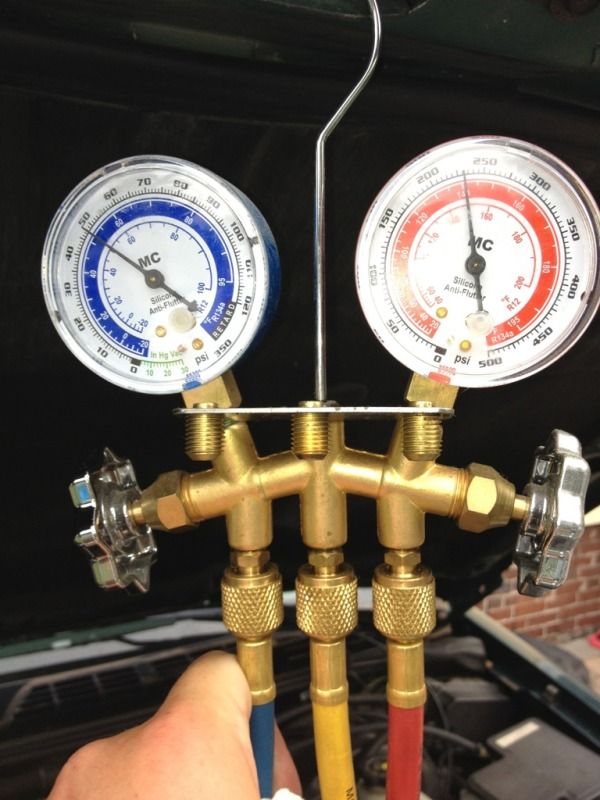

So... Ive seen a variety of recommendations on how to add refrigerant. I have 30# of R134a and US made gauges that are good and just a few years old. My thing is, I dont have a big emissions station fan to blow air at the truck, Ill be doing this in my driveway.

So what is the best approach for checking pressures and adding? Im thinking this:

1) Get a 16" house fan and blow it at the condenser.

2) Park the truck, full hot after driving in the driveway.

3) Set A/C to full blast, max setting (recirculate)

4) Set engine RPMs to 1500

5) Verify pressures and add as needed according to ambient temperature.

Is this sound? Should I crack the window or not use recirculate to add to the heat load? Should I have someone sit in the vehicle when doing this to make the heat load inside more accurate?

Thanks for any advisement.

My 98 Chevy S-10 ZR2 doesnt get a lot of use. Started it today, turned on the A/C (80F and pretty humid), and found it short cycling, though plenty cold.

Ive never touched the A/C, never added any refrigerant, etc. I thought I noticed the engagement being shorter and shorter, but it was not any big concern. I suppose I should have been a bit more proactive, but dont drive the truck a ton.

So... Ive seen a variety of recommendations on how to add refrigerant. I have 30# of R134a and US made gauges that are good and just a few years old. My thing is, I dont have a big emissions station fan to blow air at the truck, Ill be doing this in my driveway.

So what is the best approach for checking pressures and adding? Im thinking this:

1) Get a 16" house fan and blow it at the condenser.

2) Park the truck, full hot after driving in the driveway.

3) Set A/C to full blast, max setting (recirculate)

4) Set engine RPMs to 1500

5) Verify pressures and add as needed according to ambient temperature.

Is this sound? Should I crack the window or not use recirculate to add to the heat load? Should I have someone sit in the vehicle when doing this to make the heat load inside more accurate?

Thanks for any advisement.