My Prius had a torsion beam rear suspension, which is basically a solid rear axle as it has no factory adjustments for toe or camber. The solution to the lack of adjustments is to install SPC ez-shims in order to obtain the necessary amount of camber or toe change.

In order to install the shims, you need to remove the rear hub assembly and the backing plate. Then, you install the shim, followed by reinstalling the backing plate and hub. Toyota’s factory service manual states that the correct torque for the 4 hub bolts is 66 lb-ft. However, SPC states on the instructions that you should use either 38 lb-ft or 44 lb-ft for this application depending on the model of shim used. There’s also small print on the instructions that the manufacturer’s recommended torque value + 15% is a general guideline.

When I installed these shims, I used 66 lb-ft since 38 or 44 is far below the recommended amount by Toyota. When I reached 66 lb-ft, I went back to check the bolts once more and noticed that the bolts could still move. (Think of a flat tranny pan gasket, sort of.) Basically, each time I tried to turn the bolt to double-check that I had reached the appropriate torque value, the SPC shim would crush a bit more and the bolt would continue to turn. However, after 5-7 tries in a criss-cross pattern, the bolts stopped turning and the torque wrench clicked immediately at 66 ft-lbs.

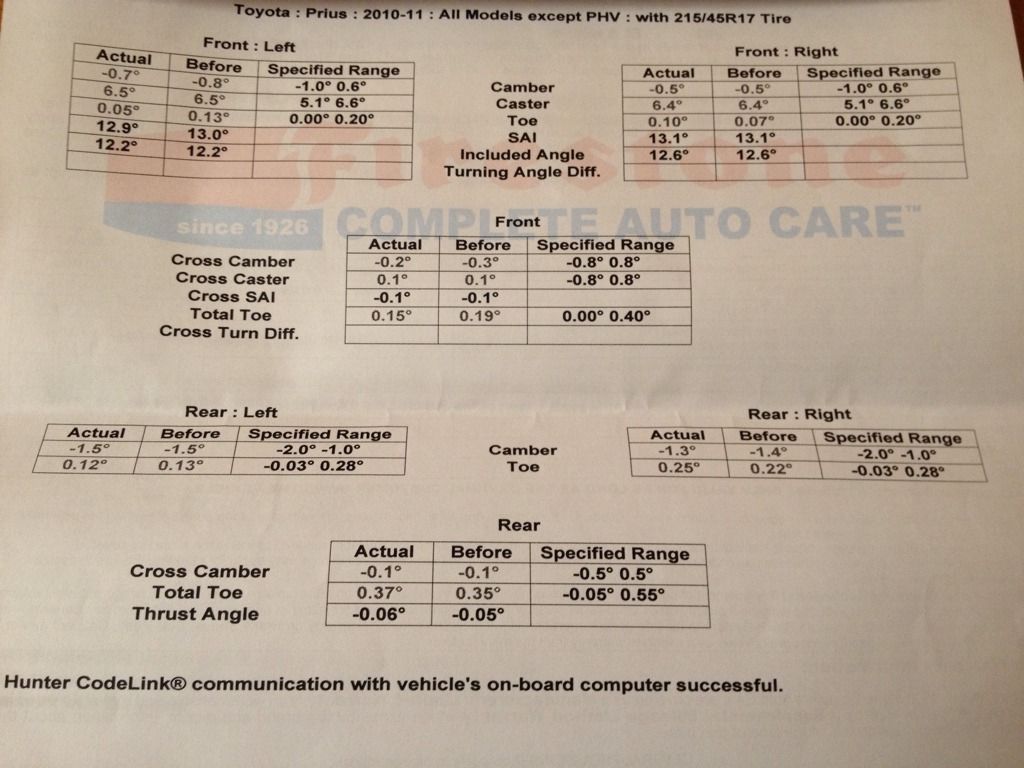

The values I was trying to target for the rear suspension was 0.14 deg of toe and -1.5 deg of camber, which are the preferred values by Toyota. I have listed below, the before/after alignment readings.

LR, before shim/after shim:

Toe: 0.33/-0.16

Camber: -1.1/-0.7

Shim used: SPC 75600, rec torque value is 44 lb-ft

RR, before shim/after shim:

Toe: 0.24/-0.16

Camber: -1.8/-1.4

Shim used: SPC 75800, rec torque value is 38 lb-ft

Clearly, something is wrong here. I arrived at the same final toe readings on both sides and the same amount of camber change on both sides. However, the values I got are not even close to what I was trying to obtain.

I called SPC’s technical hotline and I went over with them my installation procedure. We are in agreement that my installation procedure was correct, so the only possibility on the cause of these issues is the torquing of the hub bolts. I suspect that following the factory torque specs (and then some) for the hub bolts deformed the shim and caused the readings to change, since the shim does look slightly warped depending on the angle you look at it from. Tech line agreed that this maybe a possibility for my problems, and promised to research a solution.

So, my question is: can I safely use 38 or 44 lb-ft of torque for the hub bolts? Toyota recommends 66, but it is possible that this level of tightness is crushing the SPC shim too much. The hubs did feel fairly tight at 40 ft-lbs, but I also do not want the hubs to fall out.

Also, if anyone has any experience with these things, I would greatly appreciate it. Thanks!

In order to install the shims, you need to remove the rear hub assembly and the backing plate. Then, you install the shim, followed by reinstalling the backing plate and hub. Toyota’s factory service manual states that the correct torque for the 4 hub bolts is 66 lb-ft. However, SPC states on the instructions that you should use either 38 lb-ft or 44 lb-ft for this application depending on the model of shim used. There’s also small print on the instructions that the manufacturer’s recommended torque value + 15% is a general guideline.

When I installed these shims, I used 66 lb-ft since 38 or 44 is far below the recommended amount by Toyota. When I reached 66 lb-ft, I went back to check the bolts once more and noticed that the bolts could still move. (Think of a flat tranny pan gasket, sort of.) Basically, each time I tried to turn the bolt to double-check that I had reached the appropriate torque value, the SPC shim would crush a bit more and the bolt would continue to turn. However, after 5-7 tries in a criss-cross pattern, the bolts stopped turning and the torque wrench clicked immediately at 66 ft-lbs.

The values I was trying to target for the rear suspension was 0.14 deg of toe and -1.5 deg of camber, which are the preferred values by Toyota. I have listed below, the before/after alignment readings.

LR, before shim/after shim:

Toe: 0.33/-0.16

Camber: -1.1/-0.7

Shim used: SPC 75600, rec torque value is 44 lb-ft

RR, before shim/after shim:

Toe: 0.24/-0.16

Camber: -1.8/-1.4

Shim used: SPC 75800, rec torque value is 38 lb-ft

Clearly, something is wrong here. I arrived at the same final toe readings on both sides and the same amount of camber change on both sides. However, the values I got are not even close to what I was trying to obtain.

I called SPC’s technical hotline and I went over with them my installation procedure. We are in agreement that my installation procedure was correct, so the only possibility on the cause of these issues is the torquing of the hub bolts. I suspect that following the factory torque specs (and then some) for the hub bolts deformed the shim and caused the readings to change, since the shim does look slightly warped depending on the angle you look at it from. Tech line agreed that this maybe a possibility for my problems, and promised to research a solution.

So, my question is: can I safely use 38 or 44 lb-ft of torque for the hub bolts? Toyota recommends 66, but it is possible that this level of tightness is crushing the SPC shim too much. The hubs did feel fairly tight at 40 ft-lbs, but I also do not want the hubs to fall out.

Also, if anyone has any experience with these things, I would greatly appreciate it. Thanks!